Welcome To CHUANGRONG

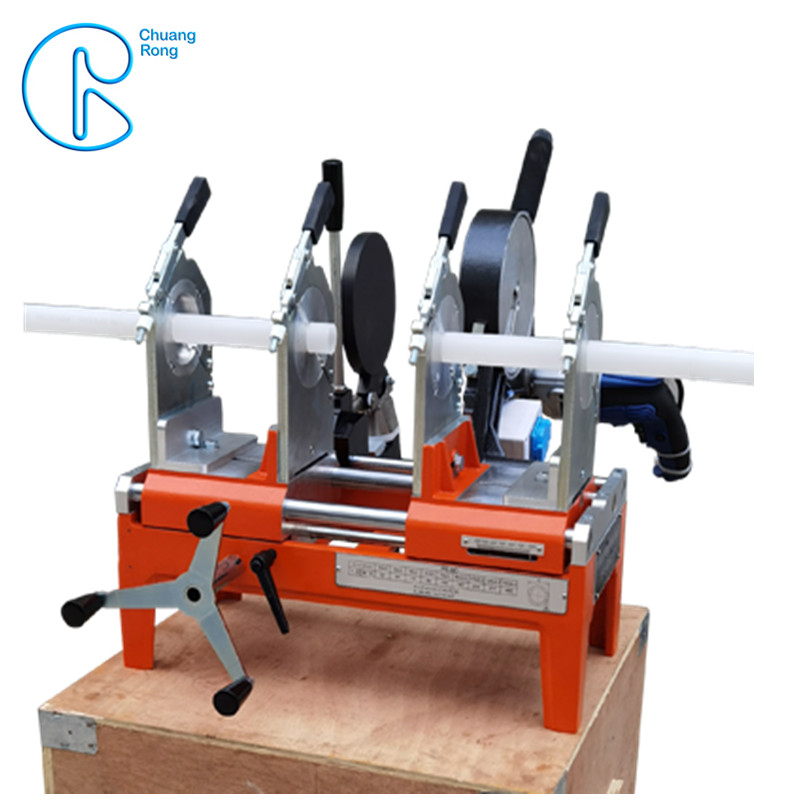

63 – 160 MM / 63 – 200 MM Plastic Pipe Manual Butt Fusion Machine One Year Warranty

Basic Information

| Product Name: | Manual Butt fusion Machine | Tube Diameter: | 63-200mm |

|---|---|---|---|

| Usage: | Plastic Pipe Butt Welding | After-sales Service Provided: | Engineers Available To Service Machinery Overseas |

| Warranty: | One year | Port: | Shanghai Or As Required |

Product Description

Single operation,suittable for use in complex construction cases.Applies to the site,a trench connecting PE,PP,PVDF pipes, pipe fittings can also be produced in the workshop.

The main body supports and centres the plastic pipe withe one (two) fixed and one movable clamps.

The milling cutter is the tool which clean and smooth the both ends of the pipes before the heating process.

The pipe ends will be heated by this heater before the welding process , butt welding machine PTFE- coated heating element and uniform surface temperuture.

The protective casing prevents heat loss of the heater and protects the trimmer from extermal effects.

Specification

| Model | CRDHS160 | CRDHS2A200 | CRDHS4A200 |

| Range(mm) | 63/75/90/110/125/140/160 | 63/75/90/110/125/140/160/180/200 | 63/75/90/110/125/140/160/180/200 |

| The Heating Plate Temperature | 170℃-250℃(±5℃)Max270℃ | 170℃-250℃(±5℃)Max270℃ | 170℃-250℃(±5℃)Max270℃ |

| Power Supply | 2.15KW | 2.45KW | 2.45KW |

| Total Weight | 45.5kg | 54.5kg | 55.5kg |

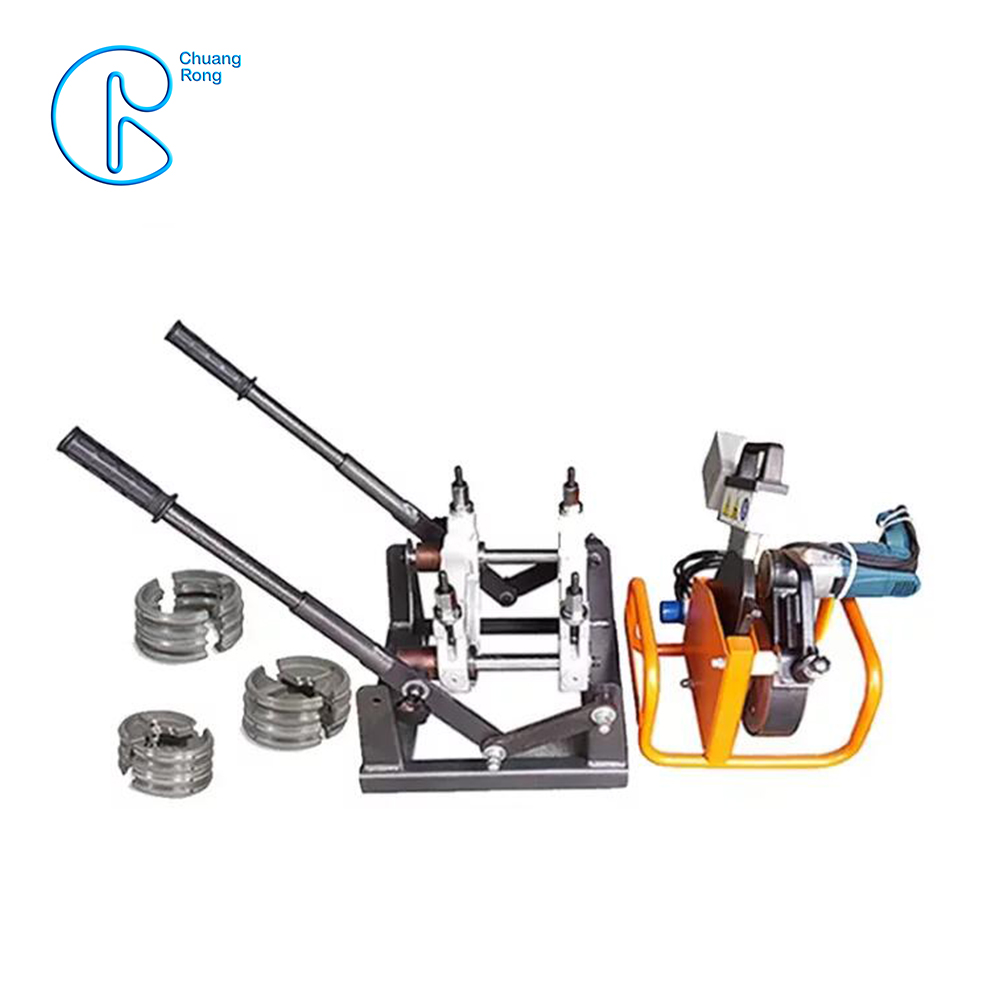

| Optional Accessory | Stub end holder,Data looger and special inserts | ||

Features

1. From the track,cutter,electric panels and frame composition

2. Heating plate with separate temperature control system,teflon coating

3. Chassis frame is made of high-strengh low-weight design

4. Electrical boxes integrated design,reducing the number of parts

Packing

Wooden casedimension : 870*520*580mm

Gross : 55KG

Application

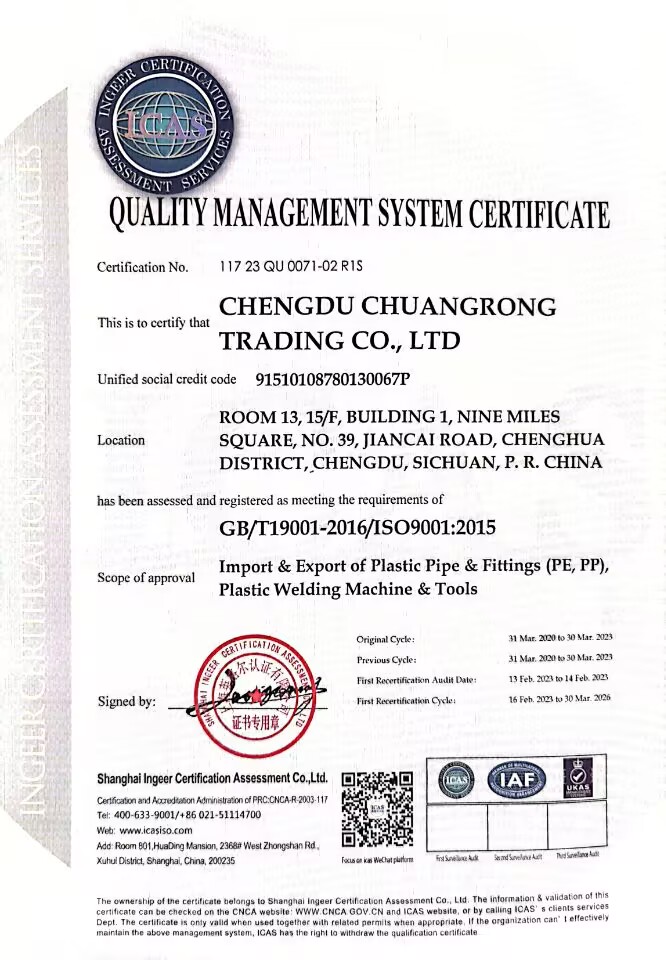

Certifiction

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top