Welcome To CHUANGRONG

China Wholesale 45 Degree Elbow Pipe Fitting Manufacturers – Water And Gas Supply HDPE Electrofusion Fittings , HDPE End Cap PN16 SDR11 PE100 – CHUANGRONG

China Wholesale 45 Degree Elbow Pipe Fitting Manufacturers – Water And Gas Supply HDPE Electrofusion Fittings , HDPE End Cap PN16 SDR11 PE100 – CHUANGRONG Detail:

Detail Information

| Product Name: | Electrofusion HDPE Fittings End Cap For Water And Gas Supply PN16 SDR11 PE100 | Specification: | 32mm~110*mm PE100 PN16 SDR11 |

|---|---|---|---|

| Standard: | EN 12201-3:2011,EN 1555-3:2010 | Application: | Gas,Water,Oil Etc |

| Material: | PE100 Virgin Raw Material | Port: | China Main Port |

Product Description

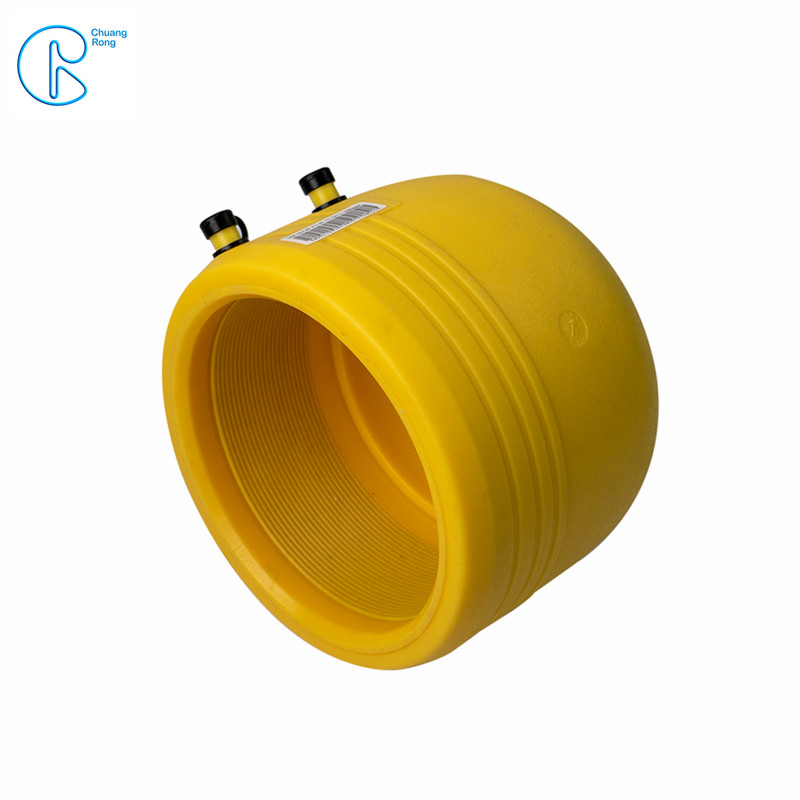

Electrofusion HDPE Fittings End Cap for Water and Gas supply PN16 SDR11 PE100

Production Description of Electrofusion HDPE End Cap

Electrofusion HDPE fittings are welded by electrofusion machine to connect HDPE pipes together:

After electrofusion welding machine plug in electricity and turn on, The copper wire buried inserted in electric fuse HDPE fittings are heated and make HDPE melt, Which joint HDPE pipe and fittings well.

Specification

| SpecificationφD | L | A | φd |

| 32 | 60 | 45 | 4.7 |

| 40 | 70 | 55 | 4.7 |

| 50 | 70 | 55 | 4.7 |

| 63 | 80 | 55 | 4.7 |

| 90 | 95 | 55 | 4.7 |

| 110 | 105 | 70 | 4.7 |

Details

| Products name | Electrofusion HDPE End Cap |

| Sizes Available | As below specification sheet in detail |

| SDR | SDR11,SDR17 |

| PN | PN16,PN10 |

| Material Brand | SINOPEC, BASELL, SABIC, BOROUGE etc |

| Executive Standard | EN 12201-3:2011,EN 1555-3:2010 |

| Colors Available | Black color , blue color, Orange or as request. |

| Packing Method | Normal export packing. by carton |

| Production Lead Time | Depending on the order quantity.Normally about 2~3 weeks for 20′ GP, 3~4 Weeks for a 40′GP. |

| Certificate | ISO, CE,BV,Factory Test Report |

| Supply Ability | 100000 Ton/Year |

| Payment Method | T/T, L/C at sight |

| Trading Method | EXW, FOB, CFR, CIF,DDU |

Factory Test report

| Test item | Standard | Conditions | Results | Unit |

| 1.Melt Flow Index | ISO1133 | 190°C & 5.0Kg 0.2-0.7 | 0.49 | g/10min |

| 2.Density | ISO1183 | @23°C ≥0.95 | 0.960 | g/cm3 |

| 3.Oxidation Induction Time | ISO11357 | 210°C >20 | 39 | Min |

| 4. Hydrostatic Pressure Test | ISO1167 | 80°C 165h, 5.4Mpa | Passed | |

| 5 Size Check | ISO3126 | 23°C | Passed | |

| 6 Appearance | Clean& Smooth | 23°C | Passed |

- The results according to test 1-3 are taken form the PE raw material supplier’s report.

- The results according to test 4-6 are taken from the internal test results of fittings sampled from the

- same batch as delivered fittings.

- Marking according EN 12201 – 3 and EN 1555 – 3.

- The pass/fail criteria are based on the requirements of the UNI EN 12201 and UNI EN 1555 standards.

Certifications

We can supply ISO9001-2008, BV ,SGS, CE etc certification.All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

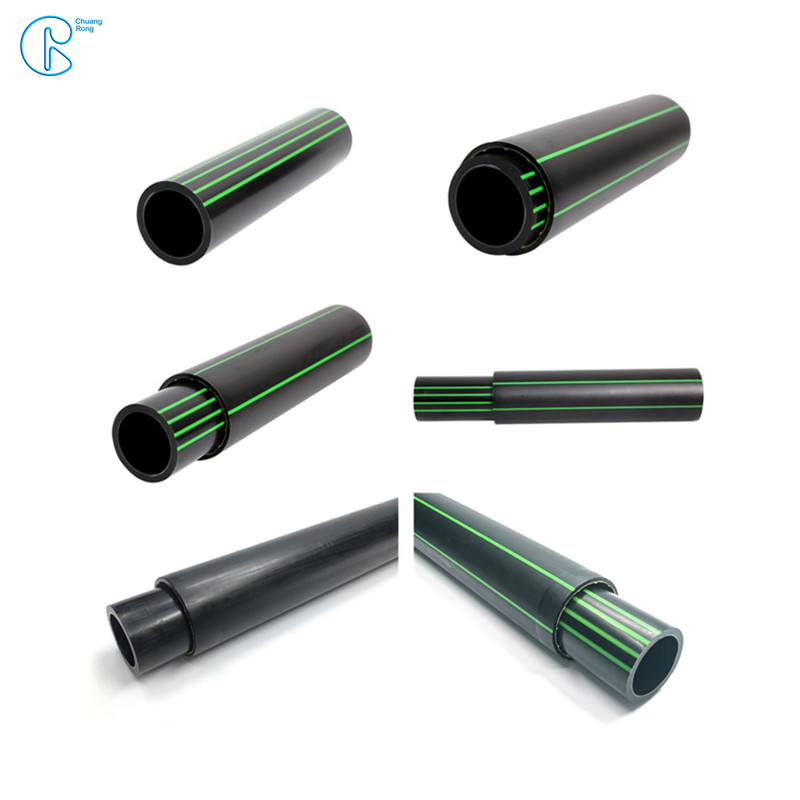

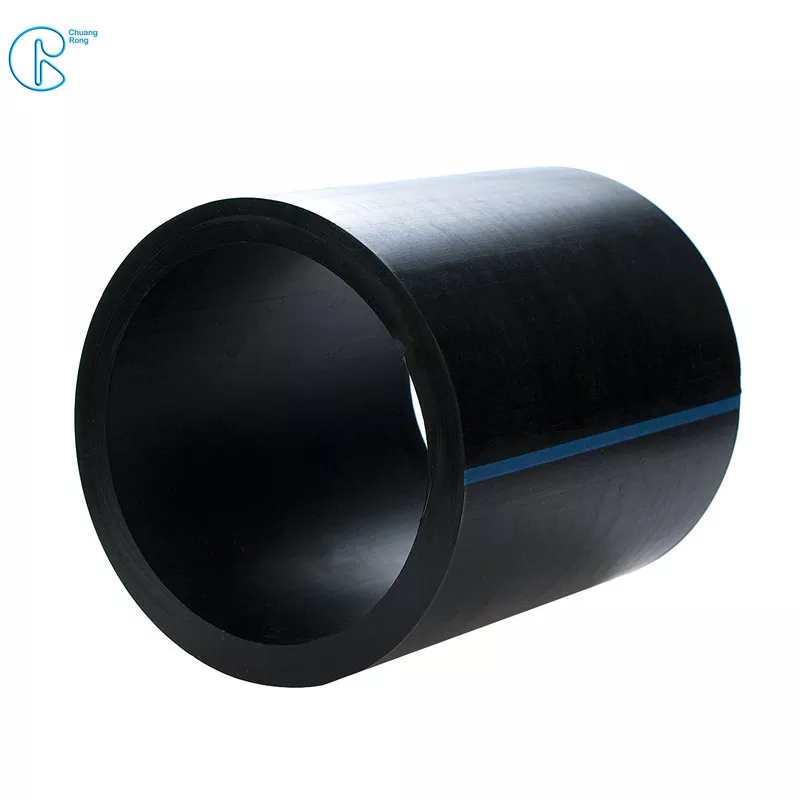

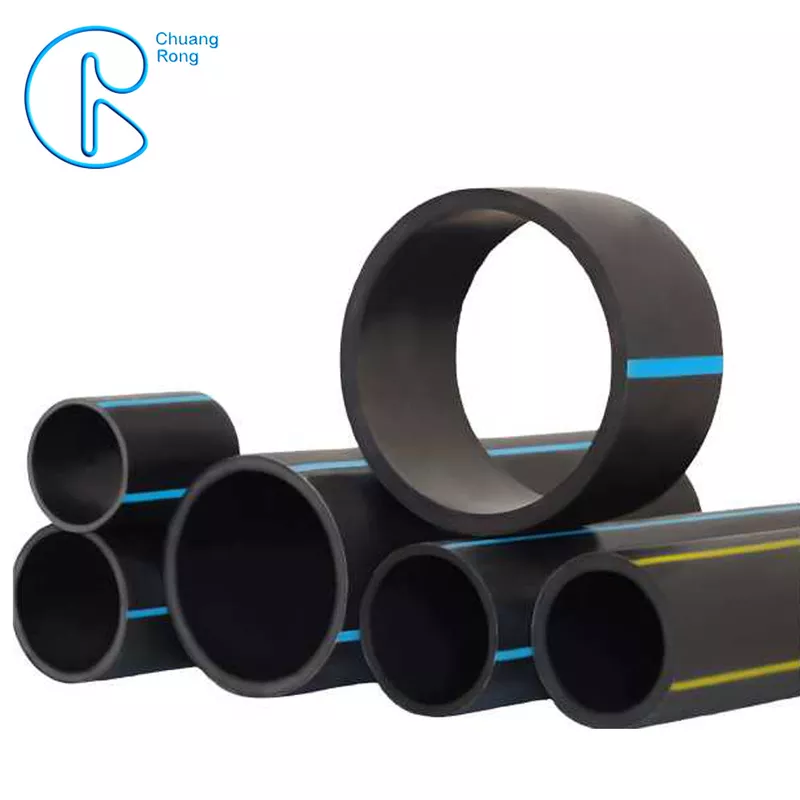

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as theory of "quality the basic, have faith in the initial and administration the advanced" for China Wholesale 45 Degree Elbow Pipe Fitting Manufacturers – Water And Gas Supply HDPE Electrofusion Fittings , HDPE End Cap PN16 SDR11 PE100 – CHUANGRONG , The product will supply to all over the world, such as: Jakarta, New York, Austria, Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products !

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top