Welcome To CHUANGRONG

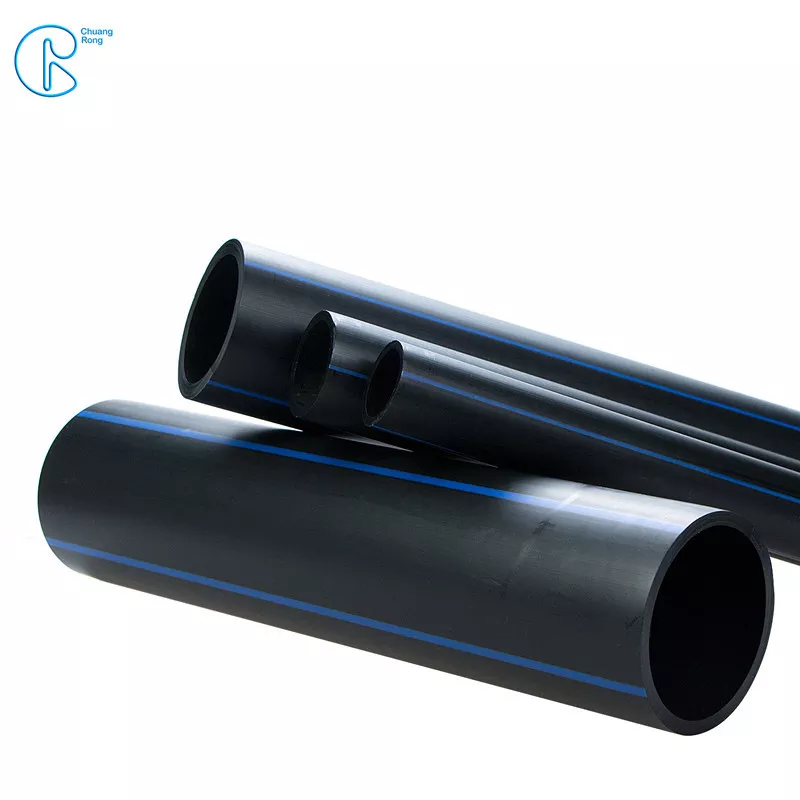

China Wholesale 63mm Pe Pipe Factory – High Density Polyethylene HDPE Pipe Polypipe for Drinking Water Supply – CHUANGRONG

China Wholesale 63mm Pe Pipe Factory – High Density Polyethylene HDPE Pipe Polypipe for Drinking Water Supply – CHUANGRONG Detail:

Basic Information

| Application: | Drinking Water Supply | Standard: | ISO4427/EN12201, DIN8074/8075 |

|---|---|---|---|

| Material: | 100% Virgin Material PE100 &PE80 | Specification: | DN20mm-1600mm |

| Product Name: | High Density Polyethylene HDPE Pipe Polypipe For Drinking Water Supply | Pipe Color: | Black With Blue Stripe |

Certificate:WRAS,ISO, CE,BV,SGS

Colors Available:Black color with blue strips, blue color, Orange or as request.

Packing Method:Normal export packing.

Pipe dia.20mm-63mm can be in coils with 50m/100m length,

Pipe dia. >63mm in bars with 5.8m/11.8m length

Production Lead Time:Depending on the order quantity.

Normally about 5 days for 20ft container, 10 days for a 40ft container.

Supply Ability:100000 Ton/Year

Payment Method:T/T, L/C at sight,West Union

Trading Method:EXW, FOB, CFR, CIF,DDU

Application of HDPE Pipe for Water Supply

Physical Properties

| No. | Item | Requirements | |

| 1 | Percentage of breaking-elongation,% | ≥350 | |

| 2 | Longitudinal reversion(110℃),% | ≤3 | |

| 3 | Oxidation induction time (200℃)min | ≥20 | |

| 4 | Weather resistance 1. (After the pipe has accepted the aging energy which equal to or more than 3.5GJ/m2) | 80℃ static hydraulic strength (165h) | No break, no leakage. |

| Percentage of breaking-elongation,% | ≥350 | ||

| Oxidation induction time (200℃)min | ≥10 | ||

| No | Items | HDPE Pipe |

| 1 | Molecular | ≥300 000 |

| 2 | Density | 0.960 g/cm3 |

| 3 | Tensile breaking strength | ≥28 Mpa |

| 4 | Longitudinal contraction rate of return | ≤3% |

| 5 | Breaking elongation | ≥500% |

| 6 | Resistant to corrosion | good |

| 7 | Tensile strength | ≥28Mpa |

| 8 | Static hydraulic strength | 1)20℃,cycle stress 12.4Mpa,100h,no break,no leakage |

| 2)80℃,cycle stress5.5Mpa,165h,no break,no leakage | ||

| 3)80℃,cycle stress5.0Mpa,1000h,no break,no leakage | ||

| 9 | MFR(190℃,5kg,)g/10min | ≤25% |

| 10 | Oxidation induction time (200℃)min | ≥20 |

Product Description

HDPE Pipes, Polyethylene (PE Pipe) are sorted by strength classified according to the intensity of the earlier technological

developments.

HDPE Pipe pressure classes that can be made between PN4-PN25 and the production of the desired diameter and size .

HDPE pipes system has undergone many tests. One of today’s most widely used pipe.

HDPE pipes systems which is economical, easy in handling, efficient performance, easy method of coupling,and quite useful.

Specification

| PE100 | 0.4MPa | 0.5MPa | 0.6MPa | 0.8MPa | 1.0MPa | 1.25MPa | 1.6MPa | 2.0MPa | 2.5MPa |

| Outside Diameter | PN4 | PN5 | PN6 | PN8 | PN10 | PN12.5 | PN16 | PN20 | PN25 |

| SDR41 | SDR33 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 | SDR7.4 | |

| Wall Thickness (en) | |||||||||

| 20 | - | - | - | - | - | - | 2.0 | 2.3 | 3.0 |

| 25 | - | - | - | - | - | 2.0 | 2.3 | 3.0 | 3.5 |

| 32 | - | - | - | - | 2.0 | 2.4 | 3.0 | 3.6 | 4.4 |

| 40 | - | - | - | 2.0 | 2.4 | 3.0 | 3.7 | 4.5 | 5.5 |

| 50 | - | - | 2.0 | 2.4 | 3.0 | 3.7 | 4.6 | 5.6 | 6.9 |

| 63 | - | - | 2.5 | 3.0 | 3.8 | 4.7 | 5.8 | 7.1 | 8.6 |

| 75 | - | - | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 | 8.4 | 10.3 |

| 90 | - | - | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 | 10.1 | 12.3 |

| 110 | - | - | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 | 12.3 | 15.1 |

| 125 | - | - | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 | 14.0 | 17.1 |

| 140 | - | - | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 | 19.2 |

| 160 | - | - | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 | 21.9 |

| 180 | - | - | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 | 24.6 |

| 200 | - | - | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 | 27.4 |

| 225 | - | - | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 | 25.2 | 30.8 |

| 250 | - | - | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 | 34.2 |

| 280 | - | - | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 | 38.3 |

| 315 | 7.7 | 9.7 | 12.1 | 15.0 | 18.7 | 23.2 | 28.6 | 35.2 | 43.1 |

| 355 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | 39.7 | 48.5 |

| 400 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 | 54.7 |

| 450 | 11.0 | 13.8 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 | 61.5 |

| 500 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 | - |

| 560 | 13.7 | 17.2 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 | - |

| 630 | 15.4 | 19.3 | 24.1 | 30.0 | 37.4 | 46.3 | 57.2 | 70.3 | - |

| 710 | 17.4 | 21.8 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 | 79.3 | - |

| 800 | 19.6 | 24.5 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 | 89.3 | - |

| 900 | 22.0 | 27.6 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 | - | - |

| 1000 | 24.5 | 30.6 | 38.2 | 47.7 | 59.3 | 72.5 | 90.2 | - | - |

| 1200 | 29.4 | 36.7 | 45.9 | 57.2 | 67.9 | 88.2 | - | - | - |

| 1400 | 34.3 | 42.9 | 53.5 | 66.7 | 82.4 | 102.9 | - | - | - |

| 1600 | 39.2 | 49.0 | 61.2 | 76.2 | 94.1 | 117.6 | - | - | - |

Application

HDPE pipes have been in existence sicne the mid 50’s . The experience shows tha HDPE pipes is solution to most pipe problems being recogized by clients and engineering consultants as the ideal pipe material for many pressure and non pressure applications from water and gas distrutionto gavity , sewers and surface water drainage for both new & rehabilitation projects.

Application field: Drinking water supply pipe for urban and rural area, liquidtransmission pipe in chemical, chemical fiber, food, forestry and metallurgy industry, waste water drainage pipe, mining slurry transmission pipe for mining field.

Connection Methods

Workshop

Material & Test Properties

| SI NO. | PROPERTIES | UNIT | REQUIREMENT | Experimental parameters | Experimental Method |

| 1 | Density | Kg/m³ | More than 930(base resin) | 190℃,5KG | D method of GB/T1033-1986,experimental preparation is according to GB/T1845.1-1989 : 3.3.1 |

| 2 | Melt Flow Rate (MFR) | g/10min | 0.2-1.4,and the maximum deviation should not exceed the nominal value of the mix | 190℃,5kg | GB/T3682-2000 |

| 3 | Thermal stability (oxidation induction time) | min | More than 20 | 200℃ | GB/T17391-1998 |

| 4 | Volatile content | Mg/kg | Less than 350 | Appendix C | |

| 5 | Moisture content b | Mg/kg | Less than 300 | ASTMD4019:1994a | |

| 6 | Carbon black content c | % | 2.0-2.5 | GB/T13021-1991 | |

| 7 | Carbon black dispersion c | grade | Less than 3 | GB/T18251-2000 | |

| 8 | Pigment dispersion d | grade | Less than 3 | GB/T18251-2000 | |

| 9 | Resistant to gas components | h | More than 20 | 80℃,2Mpa(ring stress) | Appendix D |

|

Bear fast crack propagation (RCP) |

|||||

| 10 | Full size (FS) experiment :Dn ≥250mmor S4 experiment:pipe wall thickness ≥15mm | MpaMpa | Full size experiment’s critical pressure Pc.fs ≥ 1.5XMOP | 0℃0℃ | ISO13478:1997GB/T19280-2003 |

| 11 | Bear slow crack propagation (En≥5mm) | h | 165 | 8℃,0.8Mpa(experiment pressure) f 80℃,0.92Mpa(experiment pressure) g | GB/T18476-2001 |

| a Non-black blends should meet the weatherability requirements in Table 6 b Water content is measured when the measured volatiles do not meet the requirements. When arbitration, the water content should be the measurement results as a basis for judging c Only apply to black mixd Only apply to non-black mix

e If the S4 test results do not meet the requirements, you can follow the full-size experiment to re-experiment to full-size experimental results as the final basis.

f PE80, SDR11 experimental parameters g PE100, SDR11 experimental parameters

|

|||||

Laboratory and Factory Inspection-Hydrostatic Test

Production and Delivery

CHUAGNRONG owns more 100 sets pipe production lines that are advanced at domestic and abroad,200 sets of fitting production equipment. The production capacity reaches more than 100 thousand tons. Its main contain 6 systems of water, gas, dredging, mining, irrigation and electricity, more than 20 series and more than 7000 specifications.

Certifications

We can supply ISO9001-2008,WRAS, BV ,SGS, CE etc certification. All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

If you have any questions, you can feel free to contact us in anytime . welcome to our company!

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for China Wholesale 63mm Pe Pipe Factory – High Density Polyethylene HDPE Pipe Polypipe for Drinking Water Supply – CHUANGRONG , The product will supply to all over the world, such as: Washington, Hungary, Kenya, we always keep our credit and mutual benefit to our client, insist our high quality service to moving our clients. always welcome the our friends and clients to come and visit our company and guid our business, if you are interested in our products, you can also submit your purchase information online, and we will contact you immediately, we keep our highly sincere cooperation and wish everything in your side are all well.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top