Welcome To CHUANGRONG

China Wholesale Factory – 89mm100mm HDPE High Density Polyethylene Pipe Mpp pipe For Cable / Electricity Wire – CHUANGRONG

China Wholesale Factory – 89mm100mm HDPE High Density Polyethylene Pipe Mpp pipe For Cable / Electricity Wire – CHUANGRONG Detail:

Detail Information

| roduct Name: | 100mm 89mm PE100 High Density Polyethylene Pipe For Cable Or Electricity Wire | Application: | For Cable Or Elctricity Wire |

|---|---|---|---|

| Material: | 100% Virgin Material PE100 | Specification: | DN63mm DN200mm DN315 PN16 SDR11 |

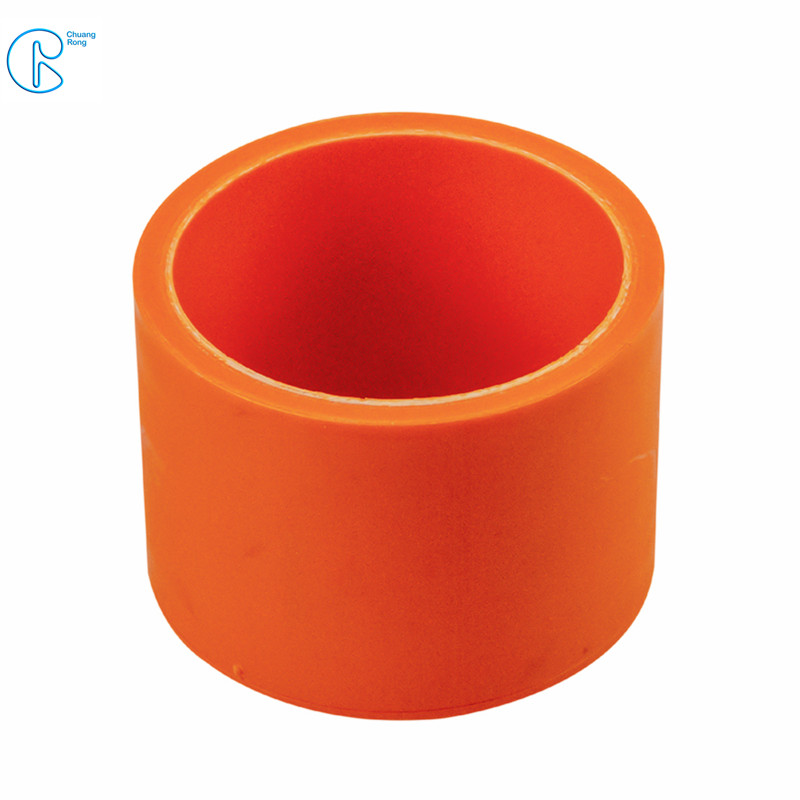

| Pipe Color: | Black With Orange Stripe | Pressure: | PN6 PN8 PN10 |

Product Description

CHUANGRONG HDPE pipe For Cable or Electricity Wire are black corlor with orange or blue strip, Which depends on requirement of end user.

MPP (modified polypropylene) pipe for electrical communication cable protection is manufactured as the new type of plastic pipe adopting modified polypropylene as the main raw material and using a special formula and processing technology,with good features of high strength,temperature resistance,handling easily,convenient installation and cost saving.The modified polypropylene trenchless pipe is widely used as the protection pipe of electrical communication cable. Its characteristics is more obvious as a towing pipe. It conforms to the development requirements of modern cities and is suitable for buried depth of 2~18m.

Physical properties index:

| Item | Index |

| Density (g/cm3) | 0.90-0.94 |

| Ring Stiffness(3%,Normal Tem,Kpa) |

SN24 ≥24 SN32 ≥32 SN40 ≥40 |

| Flattening Test (50%) | No break,no crack. |

| Hammer Impact | No break,no crack. |

| Vicat Soften Temperature ( ℃) | ≥150 |

| Tensile Strength (%) | Pipe:≥25 ; Fusion Joint: ≥22.5 |

| Elongation at Break (%) | ≥400 |

| Flexural Strength (Mpa) | ≥36 |

Specification

| E straight tube series | Nominal outer diameter | Wall thickness | Ring stiffness | Material | Package length |

| 48.3mm | 2.2mm | ≤10 level | HDPE | 6 m / root | |

| 48.3mm | 2.5mm | ≥10 level | HDPE | 6 m / root | |

| 48.3mm | 3.0mm | ≥10level | HDPE | 6 m / root | |

| 48.3mm | 4.0mm | ≥15 level | HDPE | 6 m / root | |

| 60.3mm | 2.2mm | ≤10level | HDPE | 6 m / root | |

| 60.3mm | 2.5mm | ≤10level | HDPE | 6 m / root | |

| 60.3mm | 3.0mm | ≥10level | HDPE | 6 m / root | |

| 75mm | 2.2mm | ≤10level | HDPE | 6 m / root | |

| 75mm | 2.8mm | ≤10level | HDPE | 6 m / root | |

| 75mm | 4.0mm | ≥15 level | HDPE | 6 m / root | |

| 75mm | 5.0mm | ≥15 level | HDPE | 6 m / root | |

| 89mm | 2.8mm | ≤10level | HDPE | 6 m / root | |

| 89mm | 3.5mm | ≥10level | HDPE | 6 m / root | |

| 100mm | 2.8mm | ≤10level | HDPE | 6 m / root | |

| 100mm | 3.2mm | ≤10level | HDPE | 6 m / root | |

| 100mm | 3.5mm | ≥10level | HDPE | 6 m / root | |

| 100mm | 4.0mm | ≥15 level | HDPE | 6 m / root | |

| 110mm | 2.8mm | ≤10level | HDPE | 6 m / root | |

| 110mm | 3.2mm | ≤10level | HDPE | 6 m / root | |

| 110mm | 3.5mm | ≥10level | HDPE | 6 m / root | |

| 110mm | 4.0mm | ≥15 level | HDPE | 6 m / root | |

| 160mm | 5.0mm | ≥10level | HDPE | 6 m / root | |

| 160mm | 6.0mm | ≥15 level | HDPE | 6 m / root | |

| 160mm | 7.0mm | ≥15 level | HDPE | 6 m / root |

MPP PIPE:

| Outside diameter(mm) | Thickness(mm) | Length(mm) | ||

| Ring stiffness (3% ) Normal temperature | ||||

| SN24 | SN32 | SN40 | ||

| 110 | 6 | 8 | 10 | 6000 |

| 160 | 10 | 12 | 14 | |

| 180 | 12 | 14 | 16 | 9000 |

| 200 | 14 | 16 | 18 | |

| 225 | 16 | 18 | 20 | 12000 |

| 250 | 18 | 20 | 22 | |

1. M-PP pipe has excellent electrical insulation.

2. M-PP pipe has higher thermal deformation temperature and low temperature impact performance.

3. M-PP pipe has higher tensile and compression resistance than HDPE.

4, M-PP pipe is light, smooth, frictional resistance is small, can be hot-melt butt joint.

5, M-PP tube long-term use temperature-5 ~ 70 ℃.

6. Construction instructions It is strictly forbidden to drop, hit, scratch, or expose to the sun during the transportation and construction of pipes.

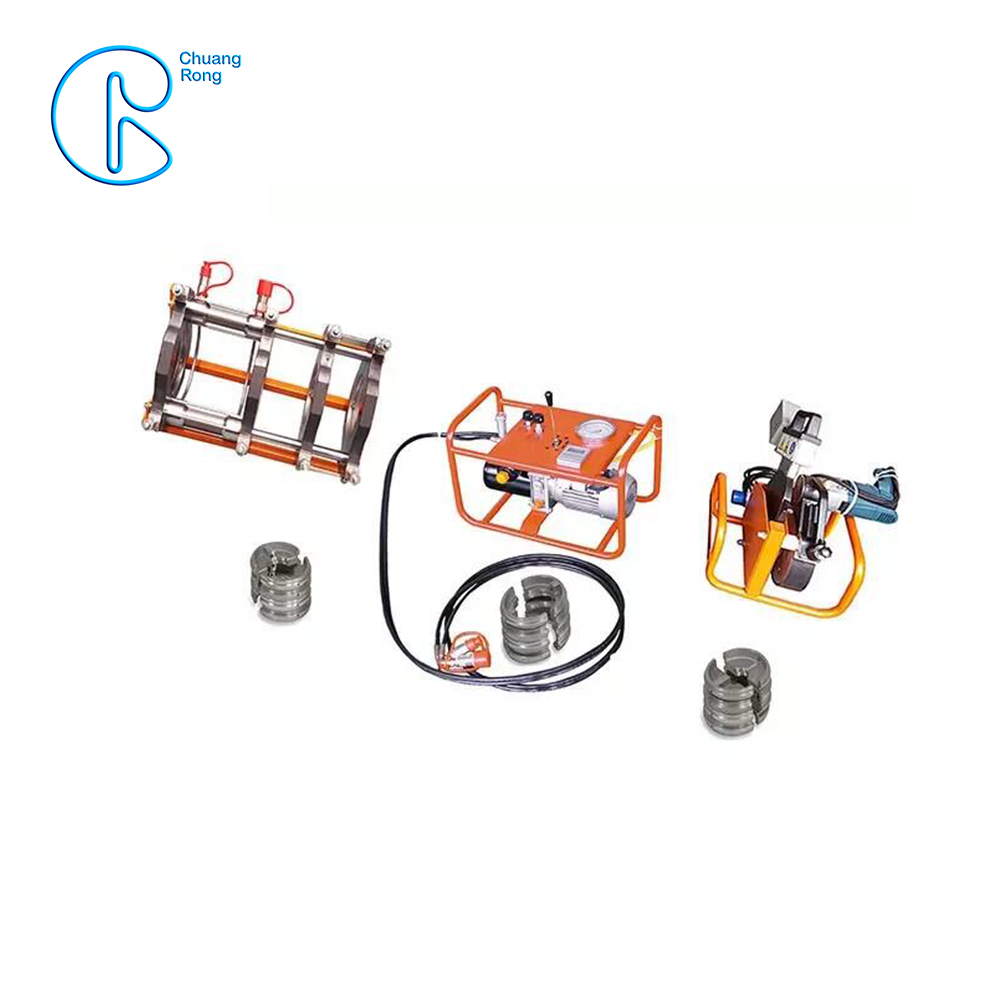

The axis of the two pipes must be aligned during the hot-melt butt joint, and the end face cutting should be vertical and flat.

The processing temperature, time, pressure, and climate conditions are adjusted accordingly. The minimum bending radius of the pipe should be ≥75 pipe outer diameter.

Application

Technology of trenchless is widely used based on its good advantages of non pollution of environment, not affect traffic, little

damage to stratigraphic texture,no need of soil transportation and pilling,cost-effective and remarkable social and economic

benefits.This kind of trenchless technology not only ensures the reliability of the network and reduces the failure rate, but also

makes the environment of the city greatly improved.There is no need to dig up and destroy the road surface largely.It is very

suitable for laying pipelines, cables and other construction works in special areas such as roads, railways, buildings and under

river etc.

Product detail pictures:

Related Product Guide:

We always continually offer you the most conscientious purchaser services, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for China Wholesale Factory – 89mm100mm HDPE High Density Polyethylene Pipe Mpp pipe For Cable / Electricity Wire – CHUANGRONG , The product will supply to all over the world, such as: Sacramento, Seychelles, Uruguay, We expect to deliver merchandise and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products and solutions all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top