Welcome To CHUANGRONG

China Wholesale Floor Trap Prices Factories – PN6 110mm HDPE Drainage Fittings Siphon Lateral Cross With Injection Technic – CHUANGRONG

China Wholesale Floor Trap Prices Factories – PN6 110mm HDPE Drainage Fittings Siphon Lateral Cross With Injection Technic – CHUANGRONG Detail:

Detail Information

| Product Name: | PN6 110mm HDPE Draining Fittings Siphon Lateral Cross | Application: | Sewage,Syphon,Drainage |

|---|---|---|---|

| Certificate: | ISO9001-2008, BV ,SGS, CE Etc Certification. | Port: | China Main Port(Ningbo,Shanghai Or As Required) |

| Technics: | Injection | Connection: | Buttfusion |

Product Description

PN6 110mm HDPE Draining Fittings Siphon Lateral Cross

| SIZE(mm) | 110*110 | 160*110 |

Description of HDPE Siphon Fittings

CHUANGRONG HDPE siphon pipes provide a one-stop solution for drainage.

System components of siphon HDPE pipeline, The complete proven and practical product range consists of:

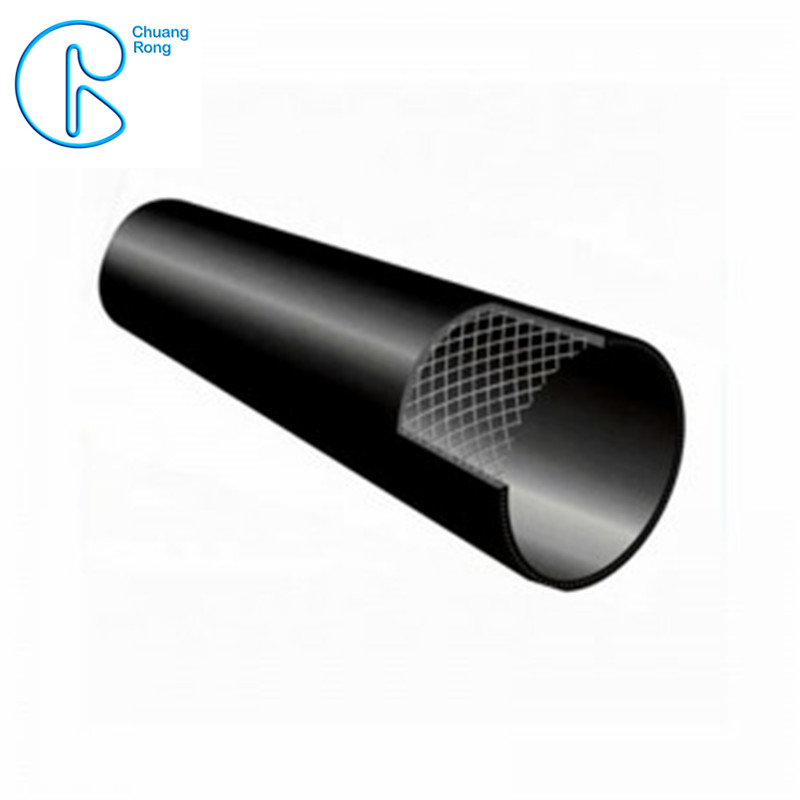

• Pipes

• Fittings

• Connections

• Fastenings

Siphon pipes and fittings are made of high-density polyethylene, it has significant advantages over traditional drainage systems. CHUANGRONG HDPE siphon pipe system has excellent mechanical properties, physical properties and chemical properties. High impact and abrasion resistance.

Resistors are very flexible and offer multiple connection options.

These comprehensive characteristics make it very suitable as a drainage material, It satisfies the needs of building drainage well, and the stable quality ensures the safety of drainage solutions.

Main Reasons to Choose us

1.Smooth inner wall, and does not change with time, small frictional resistance,save energy, the pressure loss about 30% smaller than the steel tube,can choose smaller than steel pipe diameter. Health performance is good, no additives, no possibility of pollution of drinking water, ISO standard grading polyethylene material level 0 (the lowest), no mildew material, compared with some other commonly used plastic material of polyethylene is much mildew resistance, use for a long time also not fouling.

2.Polyethylene pipe can be welded joint with pipe become an organic whole, without the possibility of joint leakage, water saving, reducing operation cost and maintenance cost examination, pipe can be manufactured in any length, but the flexible layout, saving fittings.

3.Heat expansion:The thermal expansion of HDPE also needs to be considered in the design and installation. As a rule Thumb, for every 50 ° C increase in temperature, 15 mm expansion per meter of pipe can be expected.

4.Resistance to hot water

Geberit HDPE allows temperatures up to 100 ° C for short periods of time (such as steam surges), and can be safely used as wastewater pipes without mechanical load up to 80 ° C.

5.Resistance to impact

CHUANGRONG HDPE is also very suitable for installation in The parking lot and pedestrian zone are indestructible at room temperature. Its impact resistance is very high. Even at extremely low temperatures (down to about -40 ° C).

6.Noise:HDPE limits solid conduction, However, airborne noise should be isolated. HDPE is a soft material with low Young’s modulus. This can be done through pipes or lagging.

7.Chemical resistance:CHUANGRONG HDPE has high chemical resistance: HDPE is only soluble in aliphatic and aromatic carbon and its chlorinated products exceeding 90 ° C, and insoluble in all solutions at 20 ° C. The material will be exposed to severely oxidized media (concentration HN03, concentrated H2 S04) for a long time at room temperature.

8.Tightness:After proper installation,The joints will remain watertight for the life of the building.

Because years of experience in welding. HDPE pipes have shown that butt and electric fusion.The weld forms a stronger watertight joint than the pipe.

9.PE pipe installation available welding or fused to form a completely closed seepage control system.

10.Light, easy to install, handling, connection, construction is convenient and reliable.

Application

1)Garden project: planting underground garage roof, green roof, soccer fields, golf courses, beach, saline, desert planting.2)Construction: basement floor level seepage, construction basis of the upper, lower, basement seepage level facades, insulation.3)Traffic engineering: tunnels, roads, railway embankment, dams, slope protection.4)Municipal Engineering: Metro, road embankment, landfill5)Renovation: moisture, noise, vibration, threading.

Product detail pictures:

Related Product Guide:

In an effort to provide you advantage and enlarge our business enterprise, we even have inspectors in QC Staff and assure you our greatest provider and item for China Wholesale Floor Trap Prices Factories – PN6 110mm HDPE Drainage Fittings Siphon Lateral Cross With Injection Technic – CHUANGRONG , The product will supply to all over the world, such as: venezuela, Las Vegas, Yemen, "Make the women more attractive "is our sales philosophy. "Being customers' trusted and preferred brand supplier" is the goal of our company. We've been strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top