Welcome To CHUANGRONG

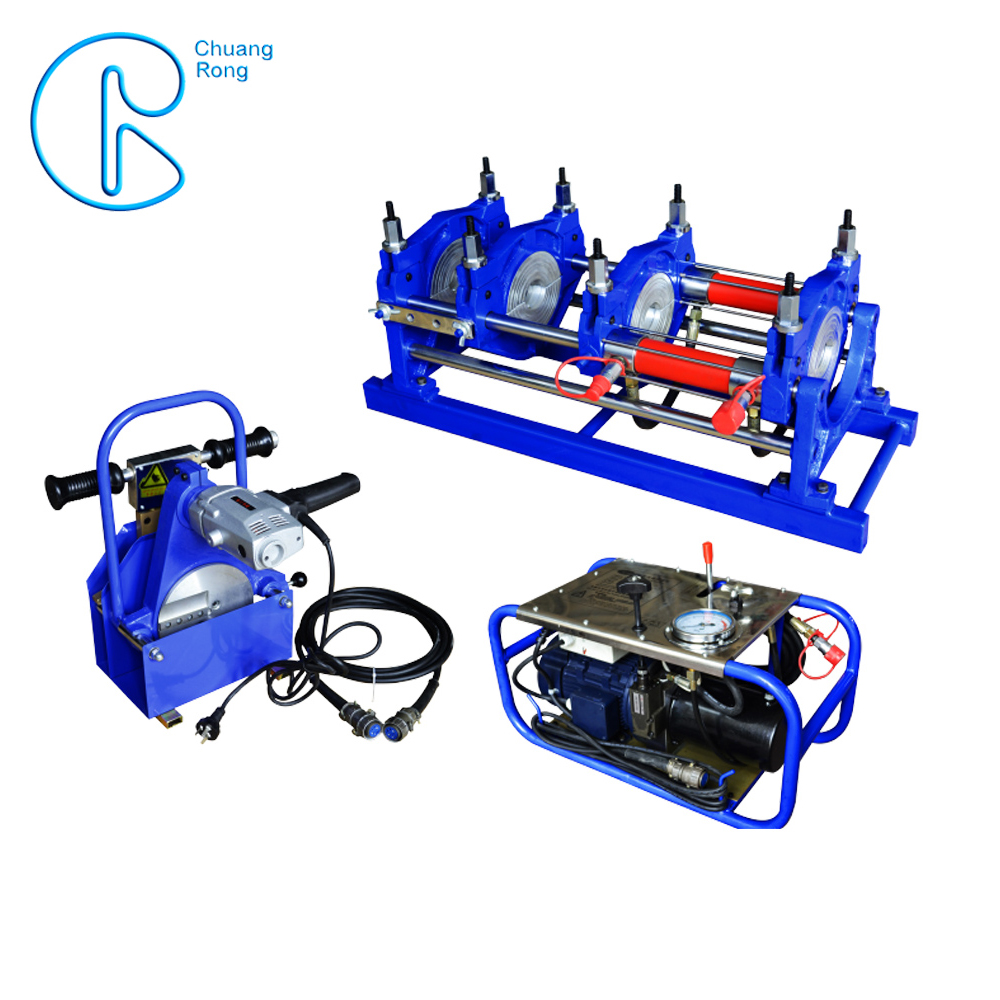

China Wholesale Hdpe Butt Fusion Welding Machine Manufacturers – 220 V / 240 V160 250 315 450 Butt Fusion Welding Machine , Plastic Hdpe Pipe Welding Machine – CHUANGRONG

China Wholesale Hdpe Butt Fusion Welding Machine Manufacturers – 220 V / 240 V160 250 315 450 Butt Fusion Welding Machine , Plastic Hdpe Pipe Welding Machine – CHUANGRONG Detail:

Basic Information

| Usage: | Welding | Working Range: | 280-450/315-500/400-630 |

|---|---|---|---|

| Power Supply: | 380/415 | Warranty: | One Year |

| Port: | China’s Major Port | Plate Tempreture: | 170-250 Celsius |

Product Description

220 V / 240 V160,250,315,450 Plastic hdpe Pipe butt fusiong welding machine

This is a self-aligning welding machine with hydraulic clamps suitable for welding under-pressure pipes for water,gas and other fluids.

Built according to international standards(UNI10565,ISO12176-1).

Application to be the site,the connection groove PE,PP,PVDF pipes,fittings can also be produced in the workshop.

Specification

| Model | CRDH 450 | CRDH 500 | CRDH 630 |

| Range(mm) | 280/315/355/400/450 | 315/355/400/450/500 | 400/450/500/560/630 |

| The Heating Plate Temperature | 170℃-250℃(±5℃)Max270℃ | 170℃-250℃(±5℃)Max270℃ | 170℃-250℃(±5℃)Max270℃ |

| Power Supply | 8.7KW | 10.3KW | 12.35KW |

| Total Weight | 388kg | 400kg | 617kg |

| Optional Accessory | Stub end holder,Crane and special inserts | ||

Uses and Features

1. From the rach,cutter,electric panels and frame composition

2. Heating plate with high precision tempreture control system,Teflon coating

3. Note departments aluminum alloy frame,lightweight structures

4. Welding position can be transformed to facilitate a variety of welding pipe fittings

5. Big accurate and shockproof pressure gauge reading clearer

FIRST CHECKS

| Instruments:Timer Pressure gauge Thermometer |

Make sure they are in good working condition.

|

|

|

Milling cutter |

Make sure that it is in good working condition. Make sure the blades are sharp enough. |

|

|

Heating plate |

Make sure the Teflon surface is free from damage.

Use a digital thermometer to check that the temperature reached corresponds to the temperature value set. |

|

|

Joint |

Test by doing experimental welding before use. | |

Application

The CRDH is an on-site welding machine equipped with a heating element for butt-welding of pipes and/or fittings made of Polyethylene (PE), Polypropylene (PP) and other thermoplastic materials intended for carrying combustible gas, water and other fluids under pressure.

The CRDHcan weld PE100 with the “Dual Pressure” method.

The use of this welding machine is only allowed to trained staff having the qualifications required by the regulations in force.

Product detail pictures:

Related Product Guide:

We have been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for China Wholesale Hdpe Butt Fusion Welding Machine Manufacturers – 220 V / 240 V160 250 315 450 Butt Fusion Welding Machine , Plastic Hdpe Pipe Welding Machine – CHUANGRONG , The product will supply to all over the world, such as: India, Swiss, Germany, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our products and services, please do not hesitate to contact us!

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top