Welcome To CHUANGRONG

China Wholesale Hdpe Coupler Pricelist – 20-110mm Hdpe Stub End , Socket Fusion Stub End PE100 PN16 SDR11 – CHUANGRONG

China Wholesale Hdpe Coupler Pricelist – 20-110mm Hdpe Stub End , Socket Fusion Stub End PE100 PN16 SDR11 – CHUANGRONG Detail:

Detail Information

| Product Name: | HDPE Socket Fusion Fittings Stub End For Water Supply PE100 PN16 SDR11 | Connection: | Socket Fusion |

|---|---|---|---|

| Size: | 20-110mm | Application: | Water Supply |

| Material: | PE100 Virgin Raw Material | Port: | China Main Port |

| Products name | Socket Joint Fusion HDPE Stub End |

| Sizes | 20-110mm |

| Connection | Socket Joint Fusion |

| Executive Standard | EN 12201-3:2011 |

| Colors Available | Black color , blue color, Orange or as request. |

| Packing Method | Normal export packing. by carton |

| Production Lead Time | Depending on the order quantity.Normally about 15-20 days for 20ft container, 30-40 days for a 40ft container |

| Certificate | WRAS,CE,ISO,CE |

| Supply Ability | 100000 Ton/Year |

| Payment Method | T/T, L/C at sight |

| Trading Method | EXW, FOB, CFR, CIF, DDU |

Product Description

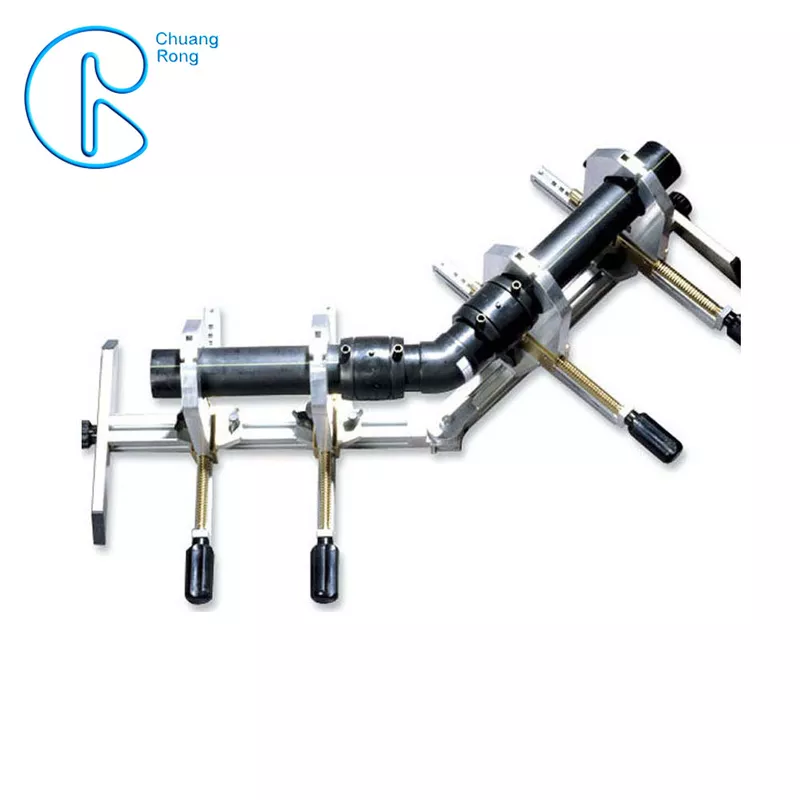

Socket fusion is distinguished from butt-welding by using custom-shaped and -sized heating plates rather than a basic flat surface. These heads allow for more surface contact, reducing the time needed to heat and fuse the pipe. Socket fusion joins pipe and fittings together, rather than simply joining pipe to pipe. It requires less pressure than butt-welding and is more commonly used on smaller sizes of pipe (4″ or less). Socket welding has additional advantages of requiring less machinery and is more portablethan the heavier equipment required for butt fusion.

Specification

| SPECIFICATIONφD | QUANTITY(PC) | BOX SIZE(W×L×D)mm | Unit Volumn(cbm) | NW/CTN(KG) |

| 40 | 200 | 50*41*26 | 0.0533 | 9.00 |

| 50 | 140 | 50*41*26 | 0.0533 | 9.10 |

| 63 | 100 | 50*41*26 | 0.0533 | 9.00 |

| 75 | 80 | 50*41*26 | 0.0533 | 10.40 |

Adavantages

1.Technology R & D of HDPE fittings

Research and development of new technologies are at the core of the company’s invincibility in an increasingly competitive global environment.

To guide our company to excellence, the R & D department must continuously create technological value.

Provide customers with more efficient and quality solutions for water and natural gas transportation, enabling our customers to improve the quality and performance of their work sites.

There is also the safety of HDPE fittings, such as geolocation of previously welded parts and reduced test time.

2.Customer-specific solutions

According to the specific needs of customers, we provide the most cost-effective solution. We produce custom parts that meet the requirements of all technical customers: we manufacture tubes of any contour and diameter.

3.Technical Support within 24 hours

Through professional, timely and effective technical assistance, close communication with customers, the fastest and efficient solution to customer problems, and the establishment of strong contacts.

4. Good service life/Long Service Life, At least 50 years of usage life.

5. Wear Resistance/Good Wear Resistance

6. Lower system and maintenance costs

7.Good Flexibility

8.Small Flow Resistance

Certificaiton

Product detail pictures:

Related Product Guide:

Having a sound small business credit score, outstanding after-sales services and modern manufacturing facilities, we've got earned an fantastic reputation among our buyers across the globe for China Wholesale Hdpe Coupler Pricelist – 20-110mm Hdpe Stub End , Socket Fusion Stub End PE100 PN16 SDR11 – CHUANGRONG , The product will supply to all over the world, such as: San Diego, Myanmar, Kenya, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top