Welcome To CHUANGRONG

China Wholesale Hdpe Coupling Fittings Factory – PE100 PN16 SDR11 Hdpe Equal Tee Socket Pipe Fitting 20-110mm For Sewage Treatment – CHUANGRONG

China Wholesale Hdpe Coupling Fittings Factory – PE100 PN16 SDR11 Hdpe Equal Tee Socket Pipe Fitting 20-110mm For Sewage Treatment – CHUANGRONG Detail:

Detail Information

| Product Name: | 20-110mm HDPE Socket Joint Fittings Equal Tee For Water Supply PE100 PN16 SDR11 | Connection: | Socket Joint Fuse |

|---|---|---|---|

| Material: | PE100 Virgin Raw Material | Application: | Water Supply |

| Standard: | EN 12201-3:2011 | Size: | 20-110mm |

Product Description

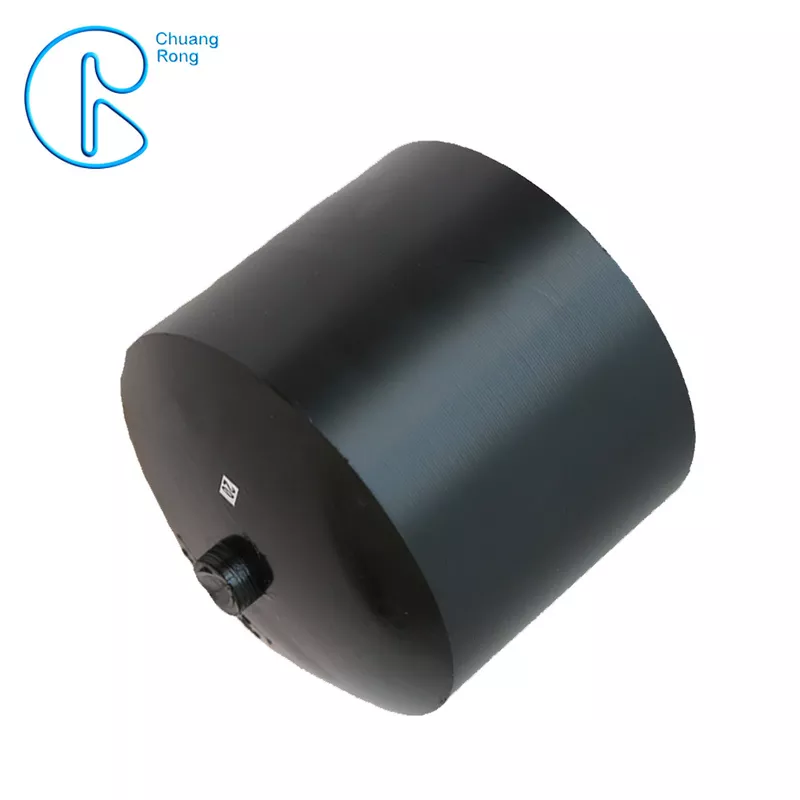

20-110mm HDPE Socket Joint Fittings Equal Tee for Water supply PE100 PN16 SDR11

Production Description of Socket Joint Or Fusion HDPE fittings

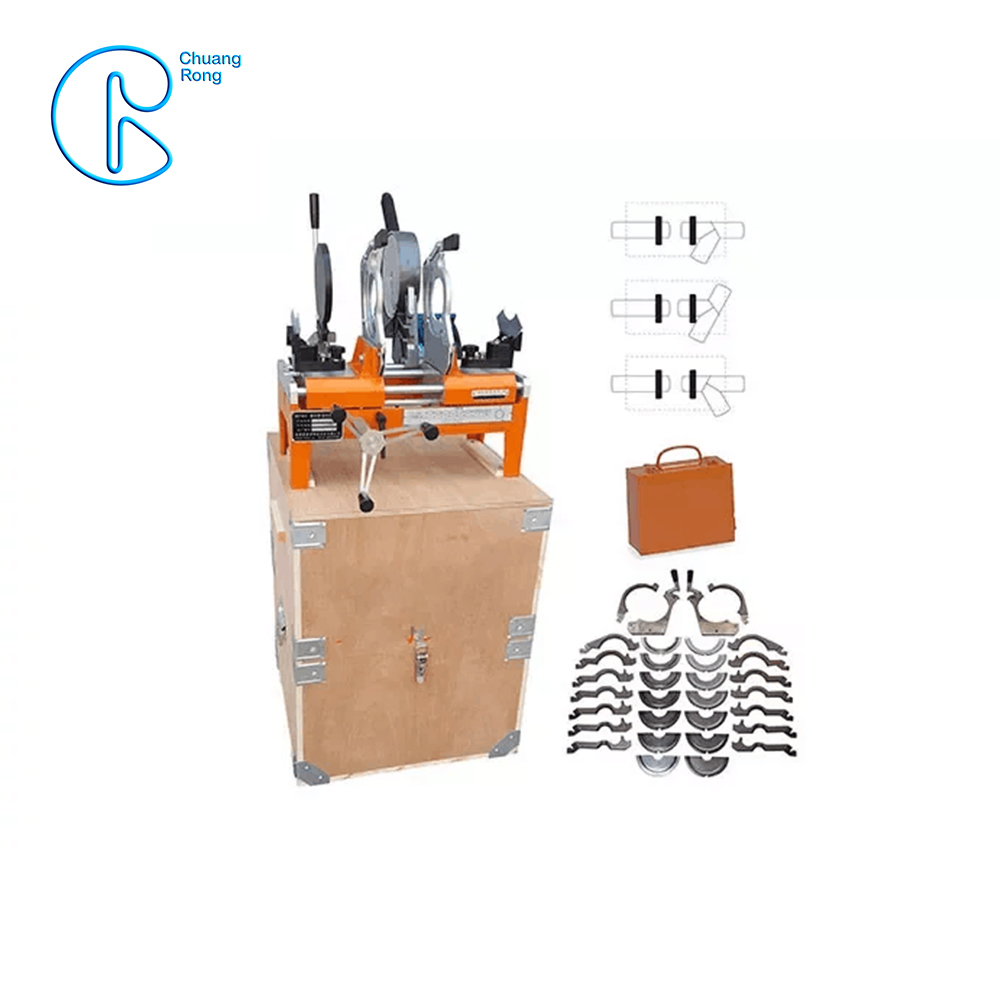

CHUANGRONG provides socket welding fittings for HDPE pipes, including a full range of types: sleeves, elbows, tees, caps, flanges, internal and external wire fittings.

The most complete specifications: 20-110mm, 20 * 1/2 “-63 * 2″

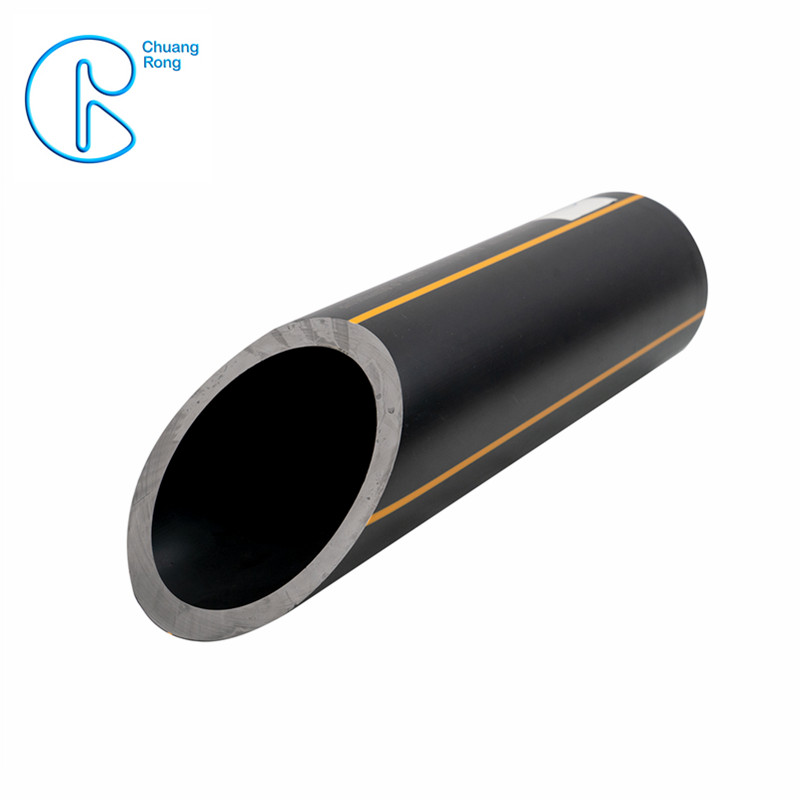

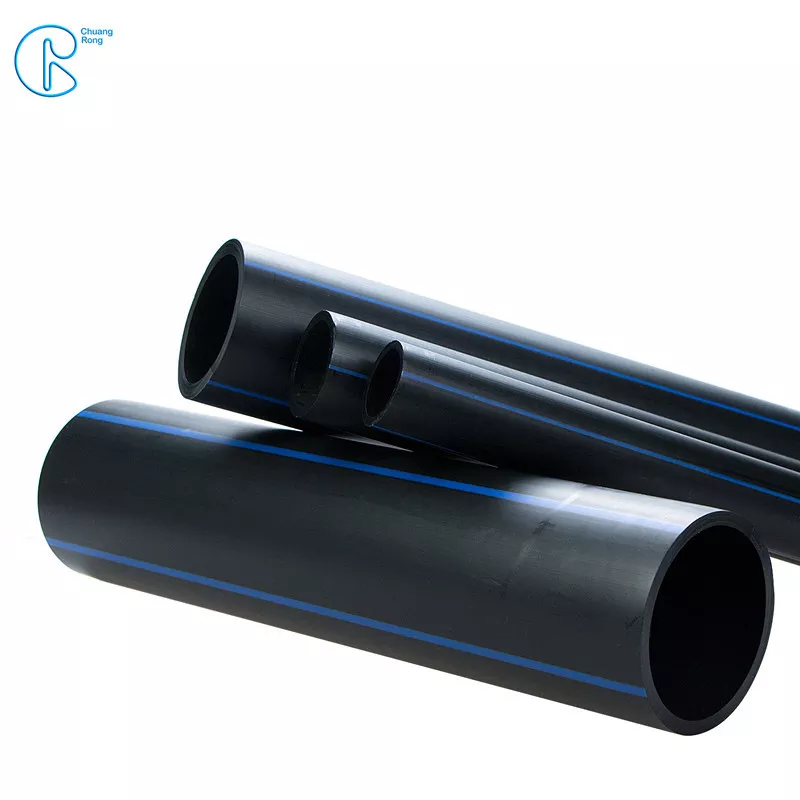

ApplicationDrinking water supply systemGardening network and sewage treatmentOld network transformation engineering systemAgricultural irrigation pipe

| Products name | Socket Joint Fusion HDPE Equal Tee |

| Sizes | 20-110mm |

| Connection | Socket Joint Fusion |

| Executive Standard | EN 12201-3:2011 |

| Colors Available | Black color , blue color, Orange or as request. |

| Packing Method | Normal export packing. by carton |

| Production Lead Time | Depending on the order quantity.Normally about 15-20 days for 20ft container, 30-40 days for a 40ft container |

| Certificate | WRAS,CE,ISO,CE |

| Supply Ability | 100000 Ton/Year |

| Payment Method | T/T, L/C at sight |

| Trading Method | EXW, FOB, CFR, CIF, DDU |

Specification

| SPECIFICATIONφD

|

QUANTITY(PC) | BOX SIZE (W×L×D)mm |

NET WEIGHT(KG) |

| 20×20×20 | 600 | 50*41*26 | 12.00 |

| 25×25×25 | 350 | 50*41*26 | 14.00 |

| 32×32×32 | 200 | 50*41*26 | 8.00 |

| 40×40×40 | 120 | 50*41*26 | 10.80 |

| 50×50×50 | 120 | 61*42*36 | 16.80 |

| 63×63×63 | 60 | 61*42*36 | 12.60 |

| 75×75×75 | 35 | 61*42*36 | 11.55 |

Adavantages

1.Production of HDPE pipe fittings

The most complete socket polyethylene pipe fittings, product types include sleeves, tees, elbows, caps, flanges, inner and outer wire fittings. Specification size range: OD20-110mm.

2.Customer-specific solutions

According to the specific needs of customers, we provide the most cost-effective solution. We produce custom parts that meet the requirements of all technical customers: we manufacture tubes of any contour and diameter.

3.Production process: injection molding

Safety, reliability and performance are ensured through the injection molding process used to make our accessories. We use state-of-the-art technology to enable us to mold accessories with diameters up to 1200mm!

4. Wear Resistance/Good Wear Resistance

5. Low Temperature Resistance

6. Lower system and maintenance costs

7.Small Flow Resistance

8.Safe and Reliable Connection Method

Details of Socket Joint Fusion HDPE Fittings

Application

1. Municipal water supply, gas supply and agriculture etc.2. Commercial & Residential water supply3. Industrial liquids transportation4. Sewage treatment5. Food and chemical industry7. Replacement of cement pipes and steel pipes8. Argillaceous silt, mud transportation9. Garden green pipe networks

Certificaiton

We can supply ISO9001-2008, BV ,SGS, CE etc certification.All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

Product detail pictures:

Related Product Guide:

We goal to understand excellent disfigurement from the manufacturing and supply the top support to domestic and abroad clients wholeheartedly for China Wholesale Hdpe Coupling Fittings Factory – PE100 PN16 SDR11 Hdpe Equal Tee Socket Pipe Fitting 20-110mm For Sewage Treatment – CHUANGRONG , The product will supply to all over the world, such as: Ukraine, Puerto Rico, Ukraine, Our items are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top