Welcome To CHUANGRONG

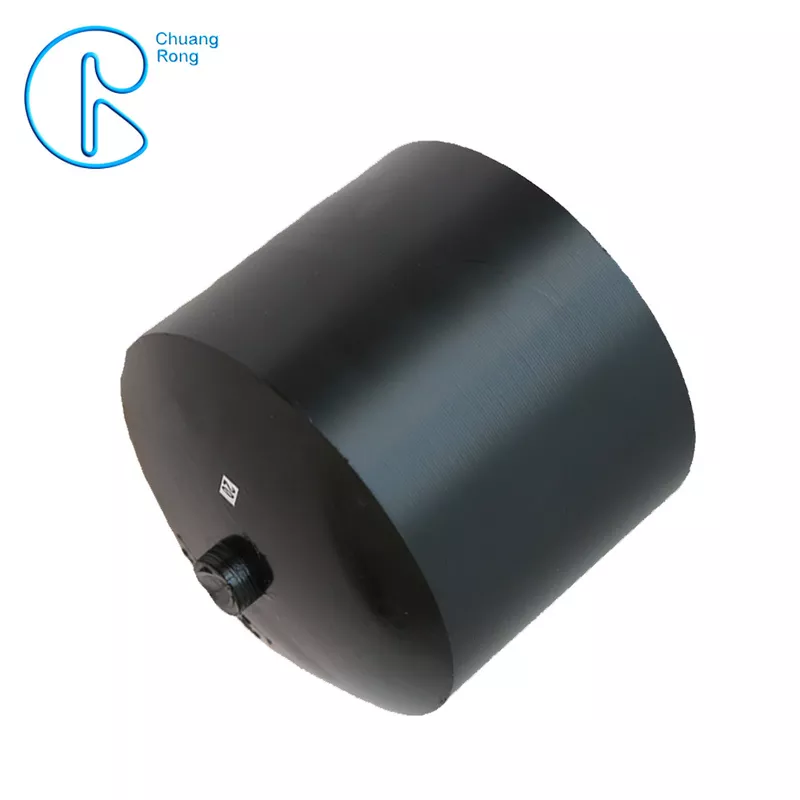

China Wholesale Hdpe Coupling Fittings Quotes – 20-75mm Hdpe Pipe Cap , Black Socket Fusion End Cap PE100 PN16 SDR11 – CHUANGRONG

China Wholesale Hdpe Coupling Fittings Quotes – 20-75mm Hdpe Pipe Cap , Black Socket Fusion End Cap PE100 PN16 SDR11 – CHUANGRONG Detail:

Detail Information

| Product Name: | HDPE Socket Fusion Fittings End Cap For Water Supply PE100 PN16 SDR11 | Size: | 20-75mm |

|---|---|---|---|

| Connection: | Socket Fusion | Material: | PE100 Virgin Raw Material |

| Application: | Water Supply | Port: | China Main Port |

| Products name | Socket Joint Fusion HDPE End Cap |

| Sizes | 20-110mm |

| Connection | Socket Joint Fusion |

| Executive Standard | EN 12201-3:2011 |

| Colors Available | Black color , blue color, Orange or as request. |

| Packing Method | Normal export packing. by carton |

| Production Lead Time | Depending on the order quantity.Normally about 15-20 days for 20ft container, 30-40 days for a 40ft container |

| Certificate | WRAS,CE,ISO,CE |

| Supply Ability | 100000 Ton/Year |

| Payment Method | T/T, L/C at sight |

| Trading Method | EXW, FOB, CFR, CIF, DDU |

Product Description

HDPE Socket Fusion Fittings End Cap for Water Supply PE100 PN16 SDR11

Production Description of Socket Joint Or Fusion HDPE fittings

Socket fusion is distinguished from butt-welding by using custom-shaped and -sized heating plates rather than a basic flat surface. These heads allow for more surface contact, reducing the time needed to heat and fuse the pipe. Socket fusion joins pipe and fittings together, rather than simply joining pipe to pipe. It requires less pressure than butt-welding and is more commonly used on smallersizes of pipe (4″ or less). Socket welding has additional advantages of requiring less machinery and is more portablethan the heavier equipment required for butt fusion.

Specification

| SPECIFICATIONφD | QUANTITY(PC) | BOX SIZE(W×L×D)mm | Unit Volumn

(cbm) |

NW/CTN(KG) |

| 20 | 1500 | 50*41*26 | 0.0533 | 7.50 |

| 25 | 1000 | 50*41*26 | 0.0533 | 10.00 |

| 32 | 800 | 50*41*26 | 0.0533 | 12.00 |

| 40 | 350 | 50*41*26 | 0.0533 | 10.50 |

| 50 | 280 | 50*41*26 | 0.0533 | 12.60 |

| 63 | 140 | 50*41*26 | 0.0533 | 11.20 |

| 75 | 100 | 50*41*26 | 0.0533 | 12.50 |

Application

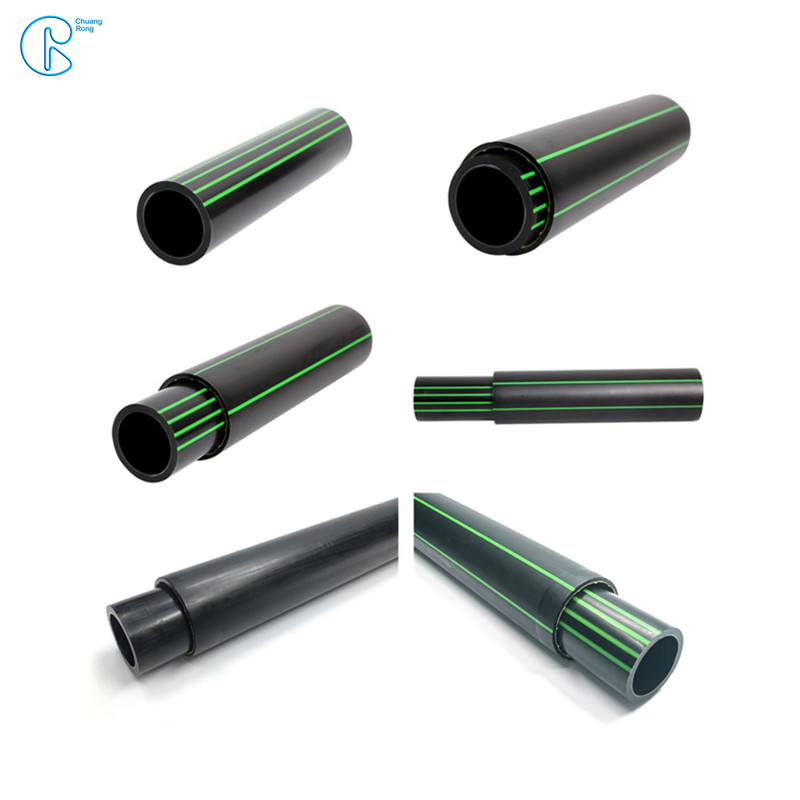

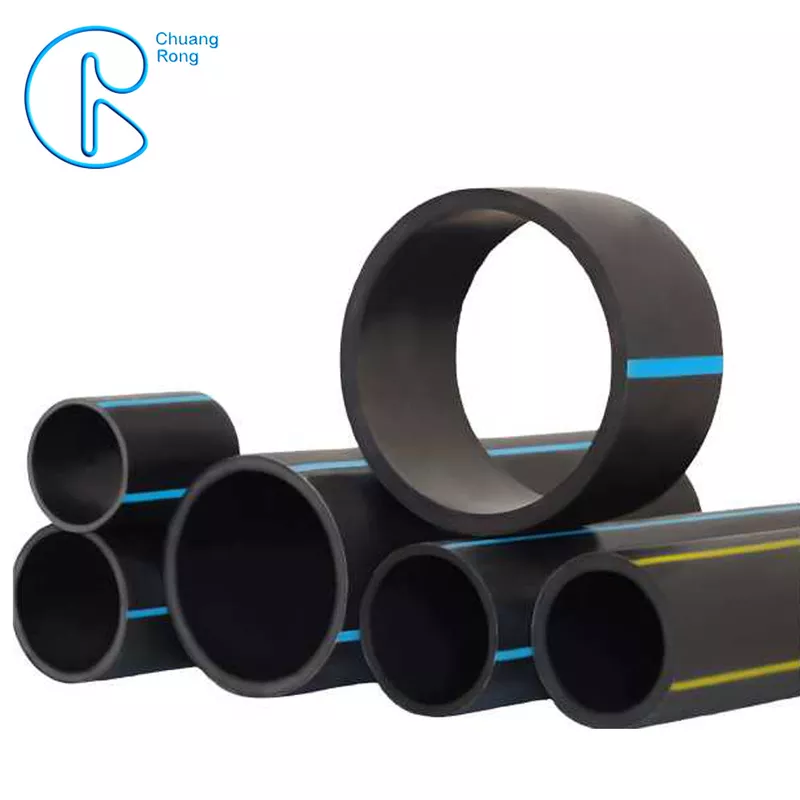

1.Municipal water supply, gas supply and agriculture etc.

2.Commercial & Residential water supply

3.Industrial liquids transportation

4.Sewage treatment

5. Food and chemical industry

7. Replacement of cement pipes and steel pipes

8. Argillaceous silt, mud transportation

9. Garden green pipe networks

Certificaiton

We can supply ISO9001-2008, BV ,SGS, CE etc certification.All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

Product detail pictures:

Related Product Guide:

Normally customer-oriented, and it's our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for China Wholesale Hdpe Coupling Fittings Quotes – 20-75mm Hdpe Pipe Cap , Black Socket Fusion End Cap PE100 PN16 SDR11 – CHUANGRONG , The product will supply to all over the world, such as: Japan, Canada, Seattle, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we've gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top