Welcome To CHUANGRONG

China Wholesale Hdpe Male Thread Adaptor Factory – Black Color HDPE Socket Fusion Fittings Reducing Tee PE100 PN16 SDR11 – CHUANGRONG

China Wholesale Hdpe Male Thread Adaptor Factory – Black Color HDPE Socket Fusion Fittings Reducing Tee PE100 PN16 SDR11 – CHUANGRONG Detail:

Detail Information

| Product Name: | HDPE Socket Fusion Fittings Reducing Tee For Water Supply PE100 PN16 SDR11 | Size: | 20-110mm |

|---|---|---|---|

| Connection: | Socket Fusion | Material: | PE100 Virgin Raw Material |

| Application: | Water Supply | Corlor: | Black |

Product Description

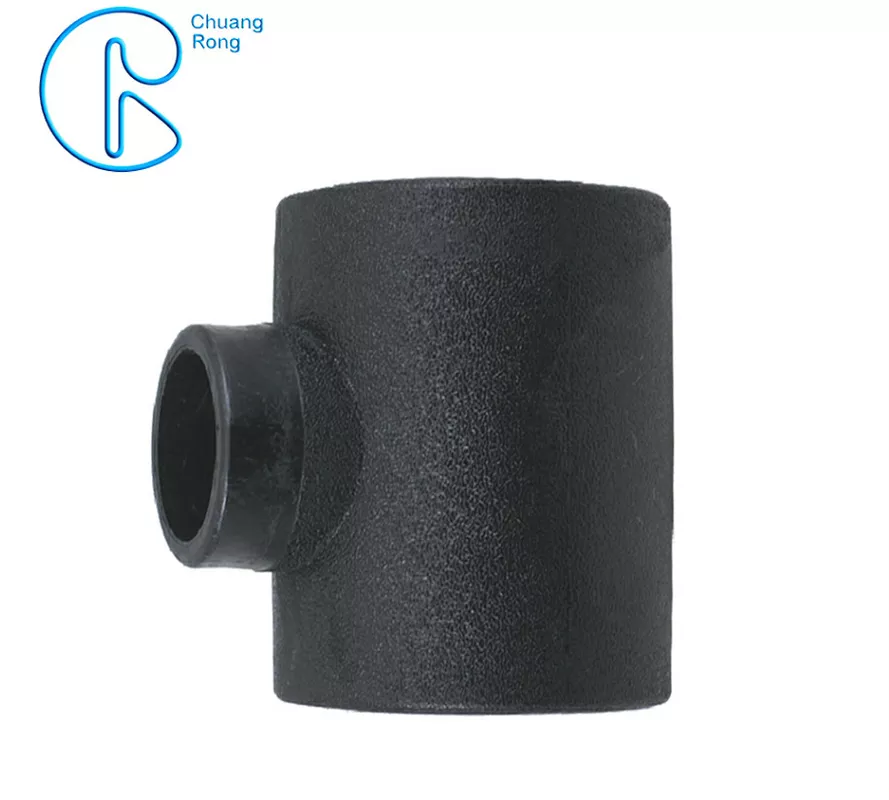

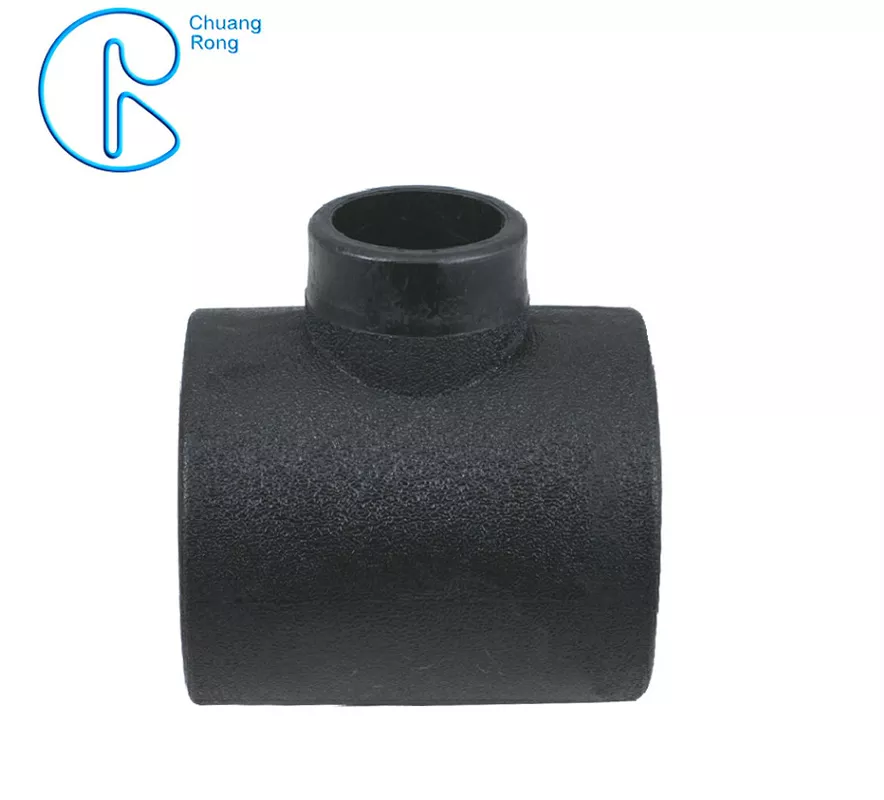

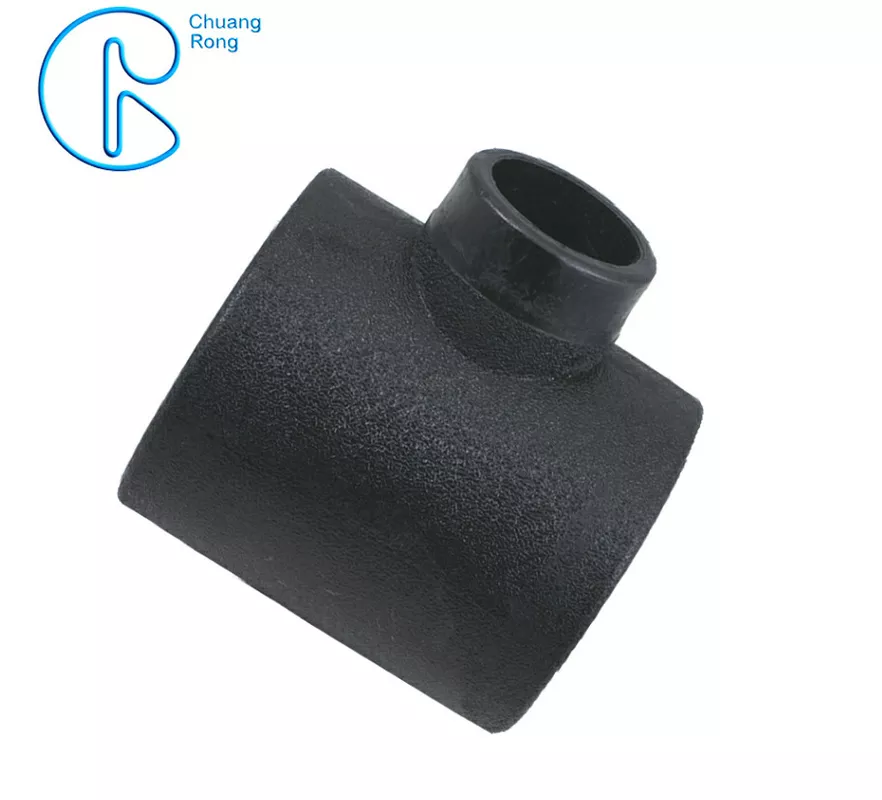

HDPE Socket Fusion Fittings Reducing Tee for Water Supply PE100 PN16 SDR11

Production Description of Socket Joint Or Fusion HDPE fittings

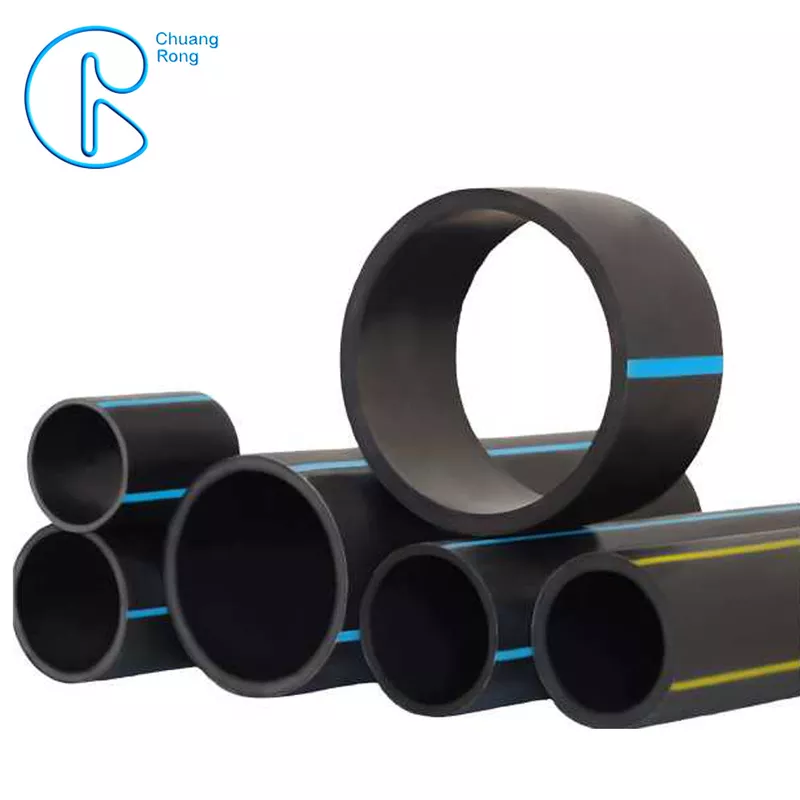

CHUANGRONG HDPE socket fittings are mainly used to connect OD20-110mm pipelines, and are used for water supply, gas, irrigation, etc. Socket welding principle: This method of connecting pipes and fittings involves a heating tool that can simultaneously heat plastic pipes and fittings to a melting point. In this case, the molten pipe can be melted by inserting it To connect the two in the socket of the accessory. Once properly inserted and allowed to cool, these two parts become a continuous bond of HDPE plastic, unable to separate and form a stronger connection than its parts.

CHUANGRONG manufactures a full line of HDPE socket fusion fittings, in which the outer diameter of the pipe is controlled over the entire thickness of the side wall. We offer stocks of the following socket welding sizes: OD20-110mm, 1/2 “, 3/4″, 1 “, 1 1/4″, 1 1/2 “, 2″. And comprehensive types: casing, elbow, tee, flange head, inner and outer wire fittings.

| roducts name | Socket Joint Fusion HDPEReducing Tee |

| Sizes | 20-110mm |

| Connection | Socket Joint Fusion |

| Executive Standard | EN 12201-3:2011 |

| Colors Available | Black color , blue color, Orange or as request. |

| Packing Method | Normal export packing. by carton |

| Production Lead Time | Depending on the order quantity.Normally about 15-20 days for 20ft container, 30-40 days for a 40ft container |

| Certificate | WRAS,CE,ISO,CE |

| Supply Ability | 100000 Ton/Year |

| Payment Method | T/T, L/C at sight |

| Trading Method | EXW, FOB, CFR, CIF, DDU |

Specification

| SPECIFICATIONφD | QUANTITY(PC) | BOX SIZE(W×L×D)mm | Unit Volumn(cbm) | NW/CTN(KG) |

| 25×20×25 | 400 | 50*41*26 | 0.0533 | 16.00 |

| 32×20×32 | 200 | 50*41*26 | 0.0533 | 12.00 |

| 32×25×32 | 200 | 50*41*26 | 0.0533 | 13.00 |

| 40×20×40 | 150 | 50*41*26 | 0.0533 | 11.25 |

| 40×25×40 | 150 | 50*41*26 | 0.0533 | 11.25 |

| 40×32×40 | 120 | 50*41*26 | 0.0533 | 10.80 |

| 50×20×50 | 160 | 63*36*28 | 0.064 | 16.80 |

| 50×25×50 | 160 | 63*36*28 | 0.064 | 17.60 |

| 50×32×50 | 160 | 63*36*28 | 0.064 | 17.60 |

| 50×40×50 | 120 | 61*42*36 | 0.093 | 17.40 |

| 63×20×63 | 120 | 61*42*36 | 0.093 | 15.60 |

| 63×25×63 | 120 | 61*42*36 | 0.093 | 15.00 |

| 63×32×63 | 120 | 61*42*36 | 0.093 | 15.00 |

| 63×40×63 | 80 | 61*42*36 | 0.093 | 14.80 |

| 63×50×63 | 80 | 61*42*36 | 0.093 | 16.00 |

| 75×40×75 | 50 | 62*36*36 | 0.08 | 15.25 |

| 75×50×75 | 50 | 62*36*36 | 0.08 | 15.75 |

| 75×63×75 | 50 | 62*36*36 | 0.08 | 15.75 |

Adavantages

1.Technology R & D of HDPE fittings

Research and development of new technologies are at the core of the company’s invincibility in an increasingly competitive global environment.

To guide our company to excellence, the R & D department must continuously create technological value.

Provide customers with more efficient and quality solutions for water and natural gas transportation, enabling our customers to improve the quality and performance of their work sites.

There is also the safety of HDPE fittings, such as geolocation of previously welded parts and reduced test time.

2.Technical Support within 24 hours

Through professional, timely and effective technical assistance, close communication with customers, the fastest and efficient solution to customer problems, and the establishment of strong contacts.

3.Impact Resistance

4. Lower system and maintenance costs

5.Excellent Shock Resistance

Certificaiton

Visit

Product detail pictures:

Related Product Guide:

We emphasize advancement and introduce new products into the market each year for China Wholesale Hdpe Male Thread Adaptor Factory – Black Color HDPE Socket Fusion Fittings Reducing Tee PE100 PN16 SDR11 – CHUANGRONG , The product will supply to all over the world, such as: Morocco, Mozambique, New Zealand, Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products ! You will be Unique with our hair products !!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top