Welcome To CHUANGRONG

China Wholesale Hdpe Pipe Fusion Welding Machine Factories – 160 / 250 / 315 mm Butt Fusion Welder Hydraulic Machine Using for Pipe Welding – CHUANGRONG

China Wholesale Hdpe Pipe Fusion Welding Machine Factories – 160 / 250 / 315 mm Butt Fusion Welder Hydraulic Machine Using for Pipe Welding – CHUANGRONG Detail:

Basic Information

| Product Name: | Butt Fusion Welder Hydraulic Machine | Input Voltage: | 220VAC |

|---|---|---|---|

| Working Range: | 63-160/90-250/160-315 | Usage: | Welding Pipes |

| Warranty: | One Year | Composition: | Machine Body,cutter,heating Plate,hydraulic Control Unit,tool Bag |

Product Description

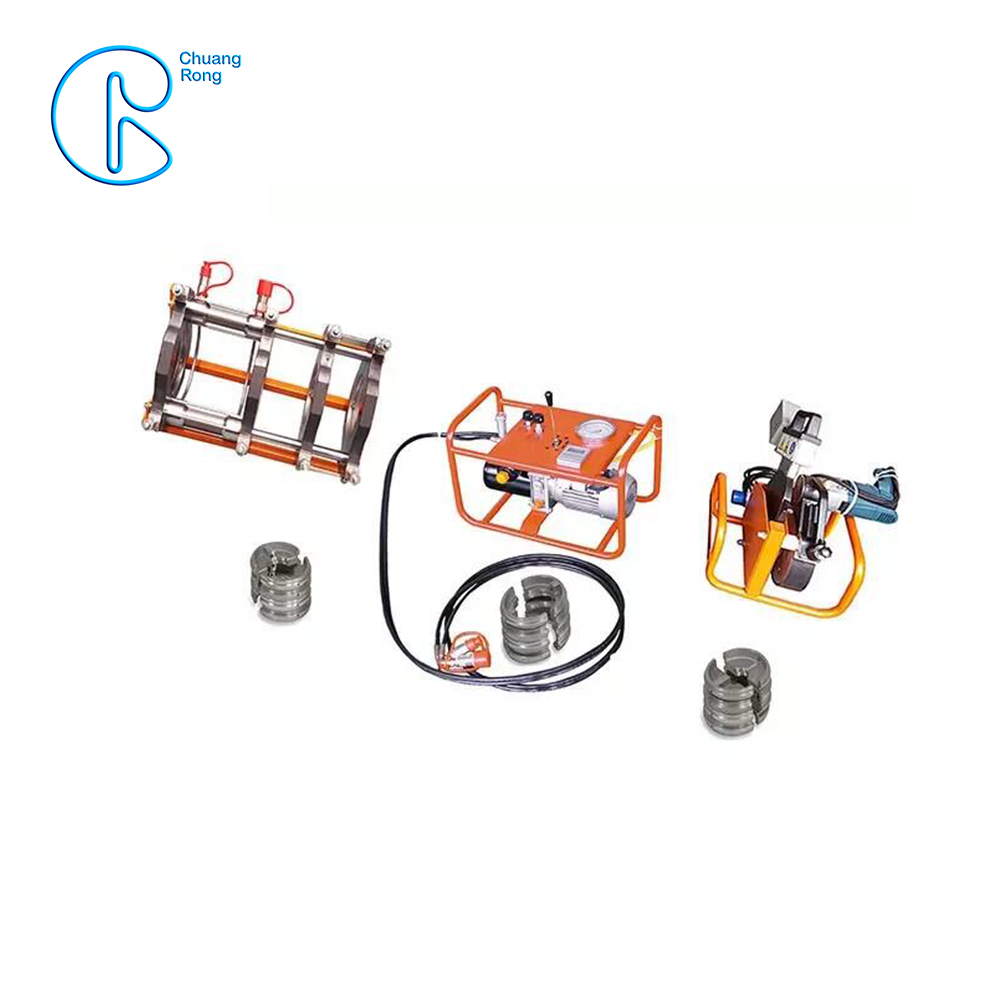

Self-aligning hydraulic butt fusion machine, suitable for welding under-pressure pipes for water, gas and other fluids. Built according to the international stands (UNI 10565, ISO12176-1). Includes:

-A machine body: built with a supporting frame, four clamps and four clamps and two hydraulic cylinders with fast non-drip coupling connections.

-A heating plate with a built -in independent thermometr, to check the working temprerature, and an high-precision electronic thermoregulator with digital display and reguating butons. Contingent probe’s failure led indicators to check if the machineis working nomally, contingent probe’s failures and/or temperate anomailies.

-Milling cutter to face the heads of the pipes and/or fitings. It includers a safety micro-switch and a thermal circuit breaker.

-An elctro-hydraulic gearcase potected from crashes and atmospheric corrosion by a plstic box. It includes a control lever, to open and close the clamps, maximum pressure and discharge vales, hydraulic connection hoses with non-drip fast coupling and timer. The machine is preset for the connection of electronic controller which come with a high-temperature -proof bag, which also protect the heating element from being scratched.

The mode is able to weld fittings like elbows ,tees, Y-branches and flanges necks.

Features

| STANDARD COMPONENTS |

160 |

250 |

315 |

|

230V |

230V |

230V |

|

| Range of diameters [mm] |

Æ 40¸160 |

Æ 75¸250 |

Æ 90¸315 |

| Materials |

Polyethylene PE-HD: PE 80(MRS 8), PE 100(MRS 10), Polypropylene PP and other thermoplastic materials |

||

| Range of ambient temperatures[° C] |

From -5 to +40 (PE 100: from 0 to +40) |

||

| Power supply |

230VAC 50/60Hz |

||

| Maximum total power absorbed [W] |

1880 |

3080 |

4420 |

| Insulation class |

1: protection conductor |

||

| Noise level [dB (A)] |

Leq=79.2 |

||

| Overall weight of standard machine [kg] |

69 |

113 |

176 |

| MACHINE BODY | |||

| Cylinders total section [cm2] |

2,498 |

5,105 |

5,890 |

| Dimensions W×D×H [mm] |

740´360´370 |

960´470´470 |

1090´620´590 |

| Weight [kg] |

27 |

54 |

100 |

| MILLING CUTTER | |||

| Nominal power [W] |

800 |

800 |

1200 |

| Fuse |

T5´20 3,15A 250V |

F5´20 5A 250V |

F5´20 5A 250V |

| Rotation speed [rev./min] |

109 |

75 |

87 |

| Dimensions W×D×H [mm] |

375´325´280 |

440´450´380 |

600´460´390 |

| Weight [kg] |

9 |

15 |

21 |

| HEATING PLATE | |||

| Maximum total absorbed power [W] |

800 |

2000 |

3000 |

| Temperature adjustment |

50¸320°C |

||

| Time for reaching working temperature |

< 20 min. |

||

| Dimensions W×D×H [mm] |

410´280´50 |

470´50´490 |

470´50´600 |

| Weight [kg] |

3 |

8 |

13 |

| ELECTROHYDRAULIC GEARCASE | |

| Nominal power [W] |

370 |

| Pressure range [bar] |

0 ¸ 150 |

| Hydraulic oil |

Viscosity class: 46 or 68 ISO 3448 Recommended oils: TEXACO RANDO HDZ 46, ESSO UNIVIS N 46 SHELL TELLUS T 46 |

| Dimensions W×D×H [mm] |

520´300´325 |

| Weight [kg] |

26 |

| Prepared for Dual Pressure welding (discharge pressure additional valve) | |

| SUPPORT FOR MILLING CUTTER / HEATING PLATE | |||

| Dimensions W×D×H [mm] |

290´280´275 |

380´265´600 |

590´315´650 |

| Weight [kg] |

4 |

10 |

16 |

WELDING PARAMETERS

9.1. PIPE / FITTING FEATURES

The following formulas and ratios apply:

|

Standard Dimension Ratio |

Series |

|

|

|

SDR |

41 |

33 |

27,6 |

26 |

22 |

21 |

17,6 |

17 |

13,6 |

11 |

9 |

7,4 |

6 |

|

S |

20 |

16 |

13.3 |

12,5 |

10,5 |

10 |

8,3 |

8 |

6,3 |

5 |

4 |

3,2 |

2,5 |

|

|

|||||||||||||

|

PN (PE 80) |

3,2 |

4 |

/// |

5 |

6 |

/// |

/// |

8 |

10 |

12,5 |

16 |

20 |

25 |

|

|

|||||||||||||

|

PN (PE 100) |

4 |

5 |

6 |

/// |

/// |

8 |

/// |

10 |

12,5 |

16 |

20 |

25 |

32 |

|

|

|||||||||||||

|

PN (PP) |

2,5 |

3,2 |

/// |

4 |

/// |

/// |

6 |

/// |

/// |

10 |

12,5 |

16 |

20 |

(Nominal Pressure at 20° C)

Herewith is a list of formulas used for calculating the welding parameters, and the tables of parameters (in compliance with various regulations for the most common diameters and thickness of pipes / fittings).

NOTE 1: The value of the approaching pressure P1, which is equivalent to that of the welding pressure P5, is to be set at the gearcase and is obtained by adding the corresponding calculated value (or obtained from one of the herewith given tables) to the value of the dragging pressure (Pt) measured by the oforator at the machine.

NOTE 2: Before consulting the tables herewith, the oforator must make sure that the real size, as measured at the pipe / fitting, actually corresponds to the nominal ones of that particular pipe / fitting. If not, and only in case the real dimensions of the pipe / fitting respect the regulated tolerances, the oforator must calculate the welding parameters by using one of the formulas herewith given. Use a callifor for this measurement.

NOTE 3: The values mentioned apply to a welding ambient at 20°C with adequate protection from adverse weather conditions.

NOTE 4: All calculations must be done in mm (pipe / fitting D diameter and s thickness).

A calculation referred to a commercial pipe (with a standard dimension) can be found next to the general formula, as an example.

Application

The ZYRD is an on-site welding machine equipped with a heating element for butt-welding of pipes and/or fittings made of Polyethylene (PE), Polypropylene (PP) and other thermoplastic materials intended for carrying combustible gas, water and other fluids under pressure.

The ZYRD can weld PE100 with the “Dual Pressure” method.

The use of this welding machine is only allowed to trained staff having the qualifications required by the regulations in force.

Product detail pictures:

Related Product Guide:

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for China Wholesale Hdpe Pipe Fusion Welding Machine Factories – 160 / 250 / 315 mm Butt Fusion Welder Hydraulic Machine Using for Pipe Welding – CHUANGRONG , The product will supply to all over the world, such as: Kuwait, Egypt, Durban, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top