Welcome To CHUANGRONG

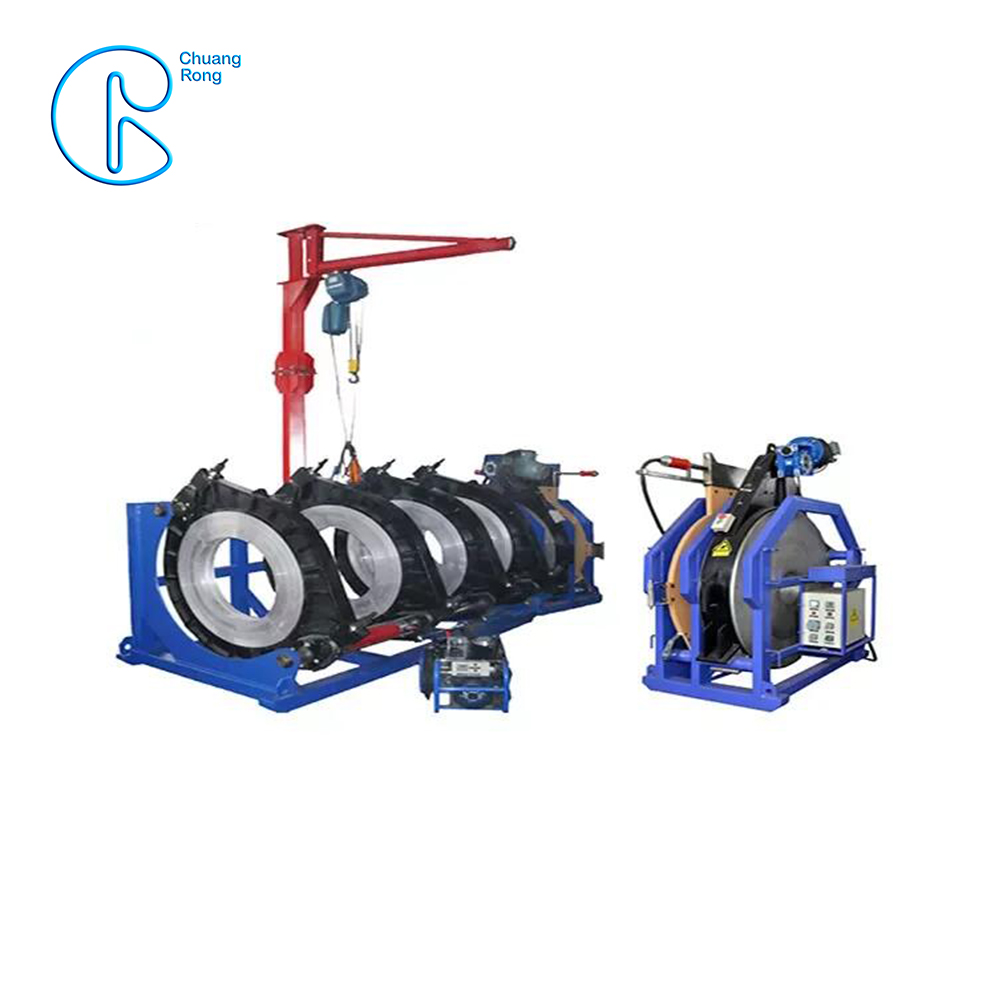

China Wholesale Hdpe Pipe Welding Machine Price Factory – Large Size Butt Fusion Welding Machine 380V/415V For Plastic Pipe Welder PE – CHUANGRONG

China Wholesale Hdpe Pipe Welding Machine Price Factory – Large Size Butt Fusion Welding Machine 380V/415V For Plastic Pipe Welder PE – CHUANGRONG Detail:

Detail Information

| Usage: | Pipe Welding | After-sales Service Provided: | Free Spare Parts, Field Installation, Commissioning And Training, Online Support, Video Technical Support |

|---|---|---|---|

| Warranty: | 1 Year | Working Range: | 630-800/800-1000 |

| Power Supply: | 380V/415V | Single Phase: | 50/60Hz |

Product Description

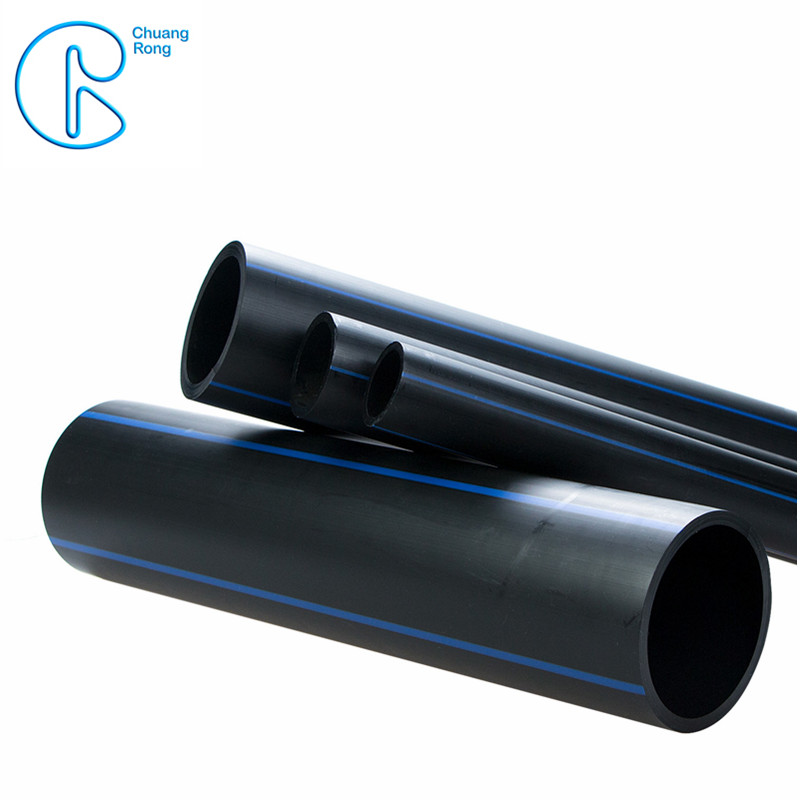

This is a self-aligning machine,suitable fore welding ducts for transport of water of and other fluids under pressure, up to dn1000mm 36” DIPS. The CRDH 1000 was designed in accordance to the International correspondent standards (UNI10565, ISO12716-1), and consistsof :

-A machine body with a bearing frame, four clamps and two hydraulic thrust cylinders with non-drip quick cooplings and steel inserts.

-An extractable heating plate with seprate thermometer for reading the working temperature.

-An extractable electrically controlled milling cutter.

-An electrohydraulic gearcase with clamping opening and closing lever.

-A milling cutrer/heating plate support.

TECHNICAL PARAMETERS

| Model | CRDH 800 | CRDH 1000 |

| Range(mm) | 630/710/800 | 800/900/1000 |

| The Heating Plate Temperature | 170℃-250℃(±7℃)Max270℃ | 170℃-250℃(±7℃)Max270℃ |

| Power Supply | 16.9KW | 26.2KW |

| Total Weight | 1440kg | 1900kg |

| Optional Accessory | Stub end holder and special inserts | |

TECHNICAL PARAMETERS

1. Applies to the site, a trench connecting PE, PP, PVDF pipes, pipe fittings can also be produced in the workshop

2. From the rack, cutter, independent heating plates and brackets

3.Frame made of high strength materials and structures, 45 ℃ tilt design

4.Electric cutter, safety limit switch to prevent accidental star-cutter5. Configuration quickly, saving the heating plate, cutter lifts

Package

| Dimension | Volume(cbm) | Net Weight(kg) | Gross Weight(kg) | Pgs | |

| CRDH 800 | Body+ Hydraulic2110*1440*1570 | 4.77 | 1000 | 1200 | |

| Basket1340*830*1700 | 1.89 | 300 | 379 | ||

| Crane2500*330*460 | 0.38 | 140 | 180 | ||

| Total | 7.04 | 1440 | 1759 | 3 cases | |

| CRDH 1000 | Basket1360*1020*2110 | 2.926 | 683 | ||

| Body+ Hydraulic2640*1790*1860 | 8.789 | 1548 | |||

Application

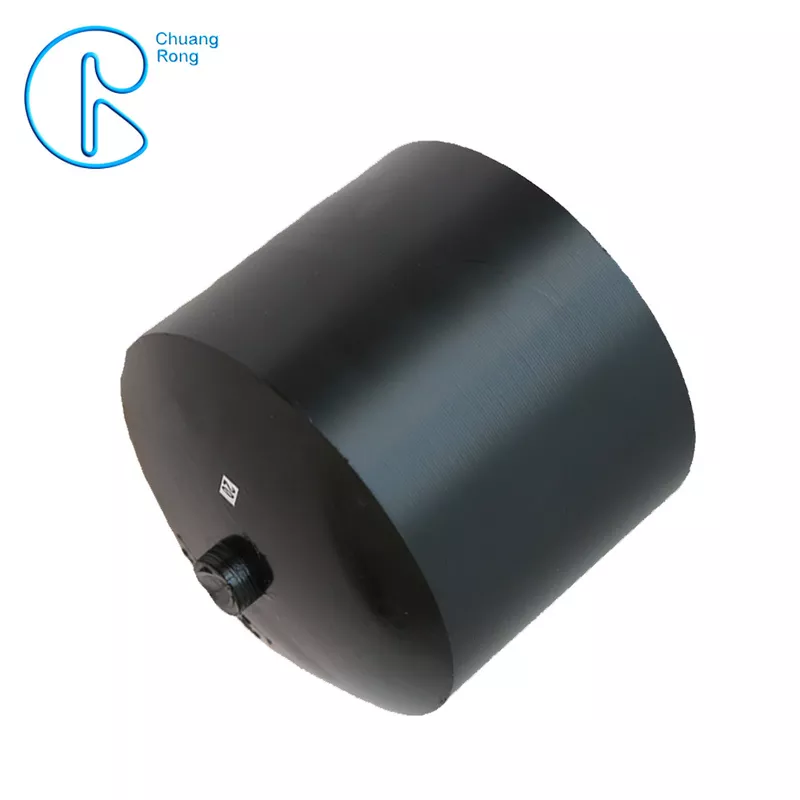

Product detail pictures:

Related Product Guide:

We will devote ourselves to giving our esteemed buyers using the most enthusiastically thoughtful services for China Wholesale Hdpe Pipe Welding Machine Price Factory – Large Size Butt Fusion Welding Machine 380V/415V For Plastic Pipe Welder PE – CHUANGRONG , The product will supply to all over the world, such as: Vancouver, Kazakhstan, Hanover, Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top