Welcome To CHUANGRONG

China Wholesale Pe Drainage Fitting Quotes – Easy To Install HDPE Siphon Fittings , Hdpe End Cap PN6 50mm 90mm 110mm160mm – CHUANGRONG

China Wholesale Pe Drainage Fitting Quotes – Easy To Install HDPE Siphon Fittings , Hdpe End Cap PN6 50mm 90mm 110mm160mm – CHUANGRONG Detail:

Detail Information

| Product Name: | PN6 50mm 90mm 110mm160mm HDPE Draining Fittings Siphon End Cap | Application: | Sewage,Syphon,Drainage |

|---|---|---|---|

| Technics: | Injection | Port: | China Main Port(Ningbo,Shanghai Or As Required) |

| Certificate: | ISO9001-2008, BV ,SGS, CE Etc Certification. | Connection: | Buttfusion |

Product Description

Product Description

PN6 50mm 90mm 110mm160mm HDPE Draining Fittings Siphon End Cap

CHUANGRONG Siphon HDPE fittings are suitable for various of application ranges in building drainage, roof drainage, Factories, Commercial or Laboratory facilities, Public buildings.

1.Siphon fittings made by HDPE have excellent chemical properties :Resistant to around 95% of all standard alkalis, acids and chemicals.And Good Physical properties mechanical properties:The siphon HDPE pipes and fittings have strong withstand shocks, drops, impacts or short-term pressure without breakage or permanent deformation.

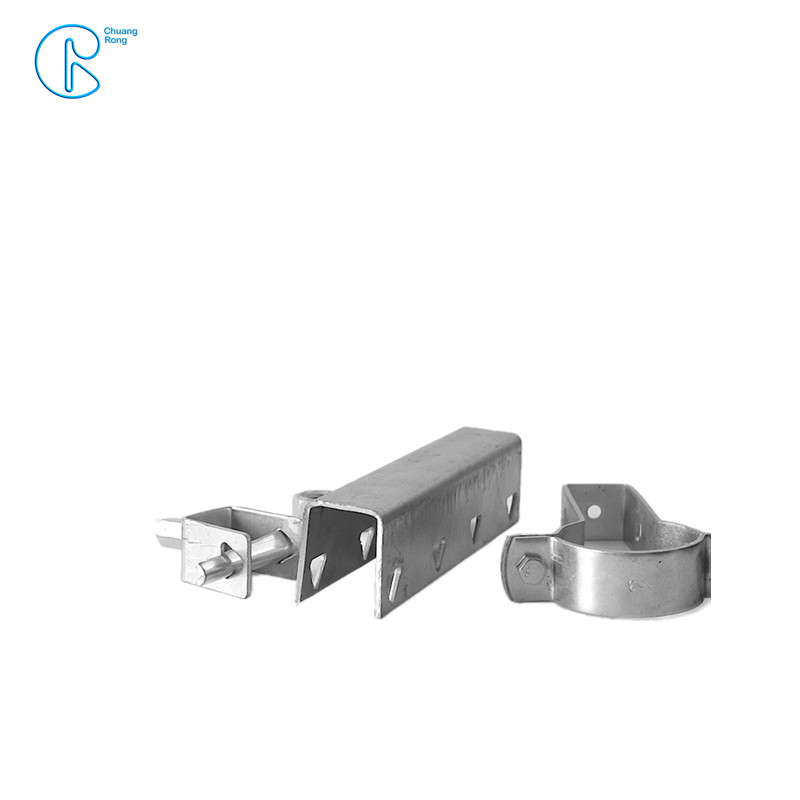

1)System composition: The siphon drainage system is mainly composed of rainwater head, fastening systems,polyethylene pipe and the corresponding design software

2) Advantage of system:Compared with the traditional gravity drainage system, the siphon drainage system without slope;less material; the construction are greatly reduced; reduction of pipe diameter;save installation space;pipe has self-cleaning function;design, construction is simple and quick; widely applicable to various purposes buildings.

3) Features:1, black PE pipeline uv resistant, ageing resistance, long service life of 50 years.

2. Smooth inner wall, and does not change with time, small frictional resistance,save energy, the pressure loss about 30% smaller than the steel tube,can choose smaller than steel pipe diameter. Health performance is good, no additives, no possibility of pollution of drinking water, ISO standard grading polyethylene material level 0 (the lowest), no mildew material, compared with some other commonly used plastic material of polyethylene is much mildew resistance, use for a long time also not fouling.

3. Polyethylene pipe can be welded joint with pipe become an organic whole, without the possibility of joint leakage, water saving, reducing operation cost and maintenance cost examination, pipe can be manufactured in any length, but the flexible layout, saving fittings.

4. PE pipe installation available welding or fused to form a completely closed seepage control system.

5. Light, easy to install, handling, connection, construction is convenient and reliable.

6. Has good flexibility, small can winding pipe, pipe winding along the ditch, can resist formation geological change, can be used as liner repairing old pipeline.

7. Good low temperature resistance, corrosion resistance, long life, buried pipeline within to 40 °C and 40 °C.

Specification

| SIZE(mm) | 50 | 63 | 75 | 90 | 110 |

Application

1)Garden project: planting underground garage roof, green roof, soccer fields, golf courses, beach, saline, desert planting.

2)Construction: basement floor level seepage, construction basis of the upper, lower, basement seepage level facades, insulation.

3)Traffic engineering: tunnels, roads, railway embankment, dams, slope protection.

4)Municipal Engineering: Metro, road embankment, landfill

5)Renovation: moisture, noise, vibration, threading.

Delivery

Certifications

We can supply ISO9001-2008, BV ,SGS, CE etc certification.All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

Product detail pictures:

Related Product Guide:

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for China Wholesale Pe Drainage Fitting Quotes – Easy To Install HDPE Siphon Fittings , Hdpe End Cap PN6 50mm 90mm 110mm160mm – CHUANGRONG , The product will supply to all over the world, such as: Uruguay, Berlin, Puerto Rico, "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, make sure you feel free to contact us. We hope to establish cooperative relationships with you in the near future.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top