Welcome To CHUANGRONG

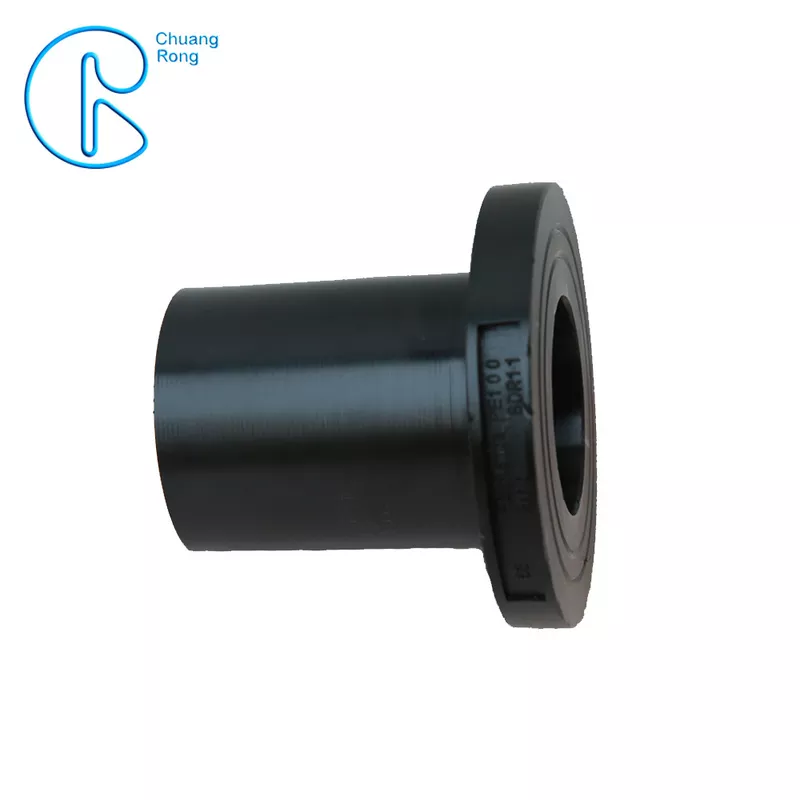

China Wholesale Pe Pipe Connector Suppliers – PN16 SDR11 PE100 HDPE Electrofusion Fittings Flange Adapter Flange Plate / Backing Ring – CHUANGRONG

China Wholesale Pe Pipe Connector Suppliers – PN16 SDR11 PE100 HDPE Electrofusion Fittings Flange Adapter Flange Plate / Backing Ring – CHUANGRONG Detail:

Detail Information

| Product Name: | Flange Plate OR Backing Ring For HDPE Electrofusion Fittings Flange Adapter For Gas And Water Supply PN16 SDR11 PE100 | Connection: | Flange Connection |

|---|---|---|---|

| Standard: | EN 12201-3:2011,EN 1555-3:2010 | Material: | Nylon Coated Flange Plate(PN16) |

| Pressure: | PN16 PN10 | Application: | Gas,Water,Oil Etc

|

Product Description

Flange plate OR Backing ring for HDPE Electrofusion Fittings Flange Adapter for Gas and Water supply PN16 SDR11 PE100

Specification

| Specification | ΦD | K | ΦE-n | ||

| PE | Steel | diameter | No. | ||

| 40 | 32 | 130 | 100 | 18 | 4 |

| 50 | 40 | 140 | 110 | 18 | 4 |

| 63 | 50 | 155 | 125 | 18 | 4 |

| 75 | 65 | 177 | 145 | 18 | 4 |

| 90 | 80 | 190 | 160 | 18 | 8 |

| 110 | 100 | 212 | 180 | 18 | 8 |

| 125 | 100 | 212 | 180 | 18 | 8 |

| 140 | 125 | 240 | 210 | 18 | 8 |

| 160 | 150 | 277 | 240 | 22 | 8 |

| 180 | 150 | 277 | 240 | 22 | 8 |

| 200 | 200 | 330 | 295 | 22 | 8 |

| 225 | 200 | 330 | 295 | 22 | 8 |

| 250 | 250 | 400 | 355 | 26 | 12 |

| 280 | 250 | 400 | 355 | 26 | 12 |

| 315 | 300 | 445 | 410 | 26 | 12 |

| 355 | 350 | 505 | 470 | 26 | 16 |

| 400 | 400 | 565 | 525 | 30 | 16 |

| 450 | 450 | 625 | 585 | 30 | 20 |

| 500 | 500 | 700 | 650 | 34 | 20 |

| 560 | 600 | 825 | 770 | 36 | 20 |

| 630 | 600 | 825 | 770 | 36 | 20 |

Performance

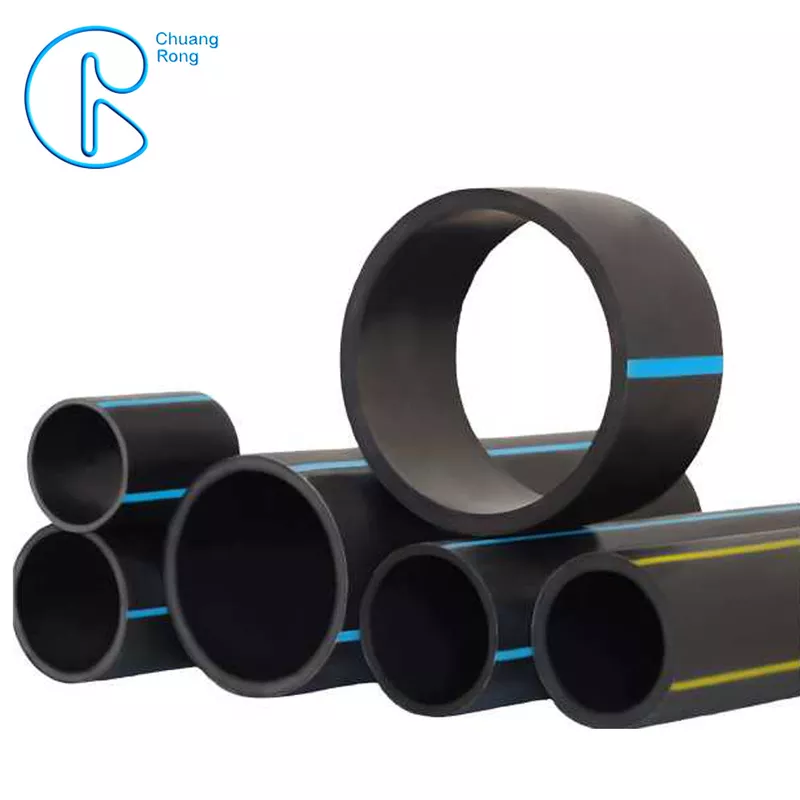

1.Cost-effective

Highest cost performance

Compared with traditional steel pipes, it is light and easy for workers to install and repair

Low installation and maintenance costs

Easy loading and transportation

Suitable for non-excavation

2.Safety and Reliability

Life span of at least 50 years

Completely maintenance-free

In all weather conditions

Excellent chemical resistance

Good impact and abrasion resistance

3.Flexiblity

Multiple connection methods, suitable for electric melting, hot melting, socket, flange connection. Electrofusion is the most efficient, time-saving, and labor-saving welding method.

CHUANGRONG provides high-, middle- and low-end brands of electric fusion welding machines to meet the various needs of customers.

Including RITMO and CHUANGRONG Brand.

4.Sustainability

Relatively low carbon footprint

Fully recyclable, environmentally friendly materials

5.Professional Solution

1) Accept customer OEM production, large quantity customization requirements.

2) Technical support:Professional engineers and senior, special engineers provide technical support:More than 80 Technique personnel,20 Middle class engineer,8 Senior Engineers.

3)More than 100 sets injection molding machine and the largest (300,000g)domestic injection molding machine; Over 20 units of automation robot, 8 sets automation Electrofusion fittings production system.

4)Various type(Elbow,Coupler,Tee,End Cap,Saddle,Ball Valve etc) and completed specification(Ranged from 20-630 Electrofusion type)

5)Annual production capacity up to 13000 tons(More than 10 million pieces or more)

6.Technical Support

The key factors of product quality are technical support and material selection

Installed successfully. Our strong and efficient teamwork provides customers with the best solution in a timely manner: the sales team understands and understands the customer’s use and proposes suitable HDPE pipeline solutions and products. The production department coordinates the production plan to ensure the fastest delivery time. Engineers and technicians solve and provide technical product performance and technical support.

7.Customized services

The team of CHUANGRONG pipeline system provides corresponding solutions according to customer needs:

Various special solutions can be produced in small batches.

Standardized processes ensure highest quality

Personalized solutions for customers.

8.Environmentally

CHUANGRONG HDPE pipeline system integrates its environmental responsibility into its daily business activities.

HDPE is a green environmental protection material, which can be recycled without causing pollution to the environment.

We work hard to conserve natural resources and constantly strive to optimize the environmental performance of our products and how they used.

Application

Certification

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for China Wholesale Pe Pipe Connector Suppliers – PN16 SDR11 PE100 HDPE Electrofusion Fittings Flange Adapter Flange Plate / Backing Ring – CHUANGRONG , The product will supply to all over the world, such as: Istanbul, Amsterdam, Tanzania, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we are going to continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top