Welcome To CHUANGRONG

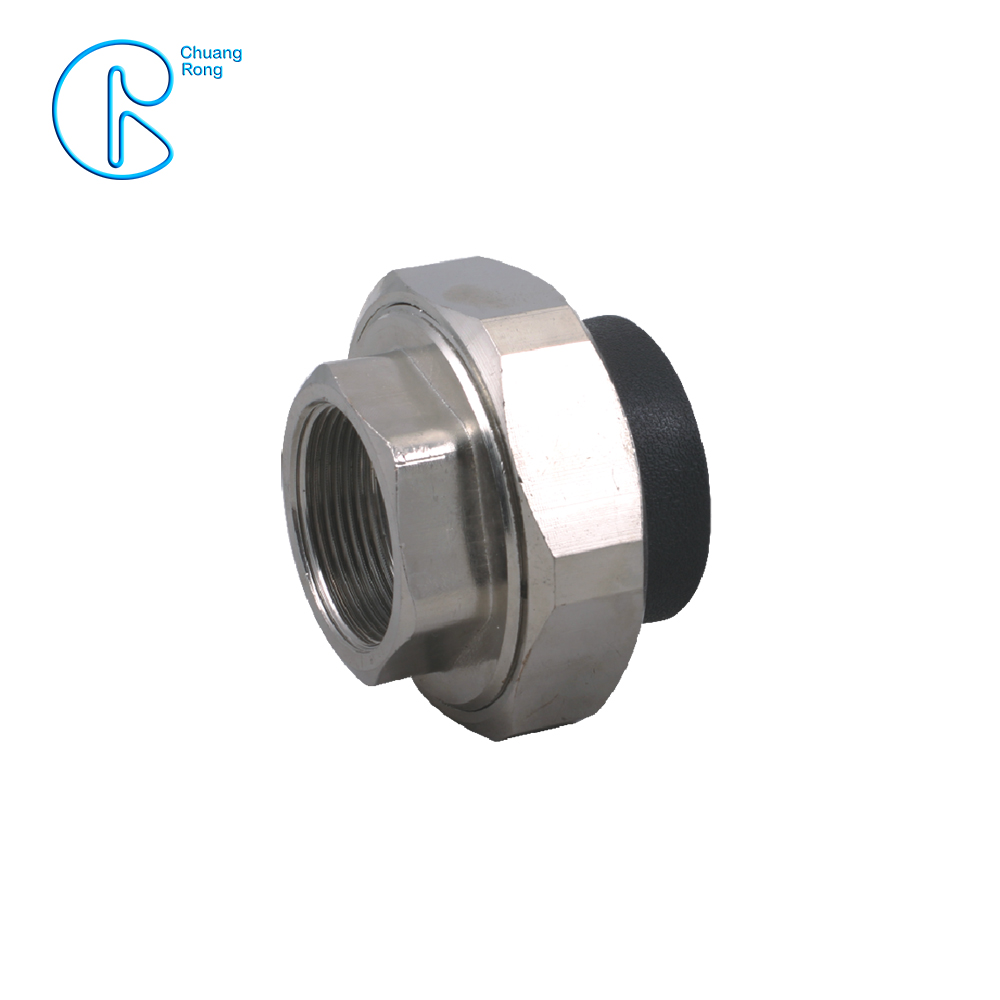

China Wholesale Socket Fusion Fittings Pricelist – PE100 PN16 SDR11 HDPE Socket Fusion Fittings Female Thread Union For Municipal Water Supply – CHUANGRONG

China Wholesale Socket Fusion Fittings Pricelist – PE100 PN16 SDR11 HDPE Socket Fusion Fittings Female Thread Union For Municipal Water Supply – CHUANGRONG Detail:

Detail Information

| Product Name: | HDPE Socket Fusion Fittings Female Thread Union For Water Supply PE100 PN16 SDR11 | Connection: | Socket Fusion |

|---|---|---|---|

| Application: | Water Supply | Size: | 20*1/2″-63*2″ |

| Material: | PE100 Virgin Raw Material | Port: | China Main Port |

| Products name | Socket Joint Fusion HDPE Female Thread Union |

| Sizes | 20*1/2″-63*2″ |

| Connection | Socket Joint Fusion |

| Executive Standard | EN 12201-3:2011 |

| Colors Available | Black color , blue color, Orange or as request. |

| Packing Method | Normal export packing. by carton |

| Production Lead Time | Depending on the order quantity.Normally about 15-20 days for 20ft container, 30-40 days for a 40ft container |

| Certificate | WRAS,CE,ISO,CE |

| Supply Ability | 100000 Ton/Year |

| Payment Method | T/T, L/C at sight |

| Trading Method | EXW, FOB, CFR, CIF, DDU |

Product Description

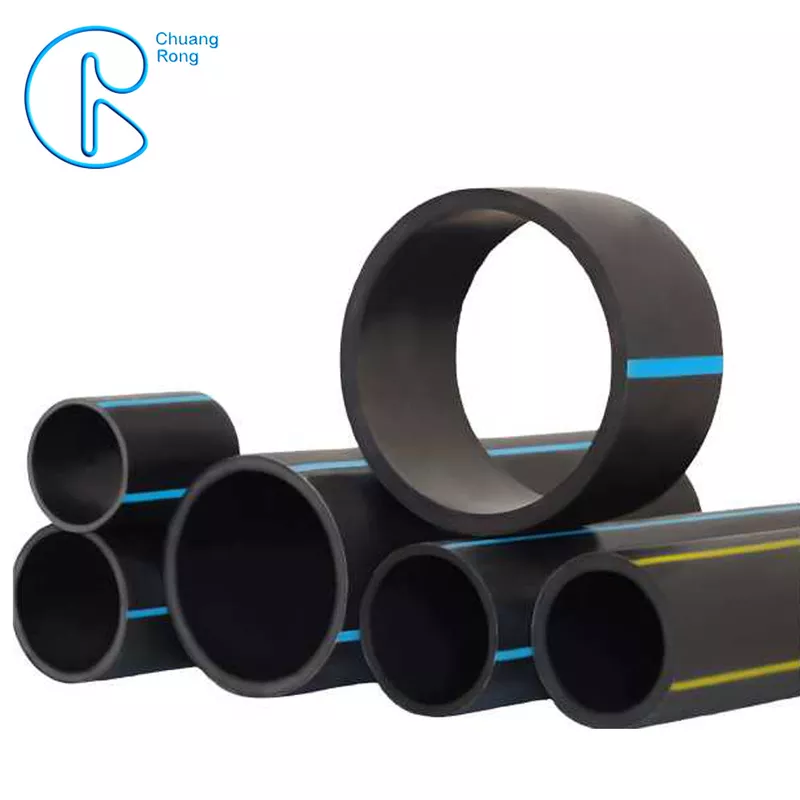

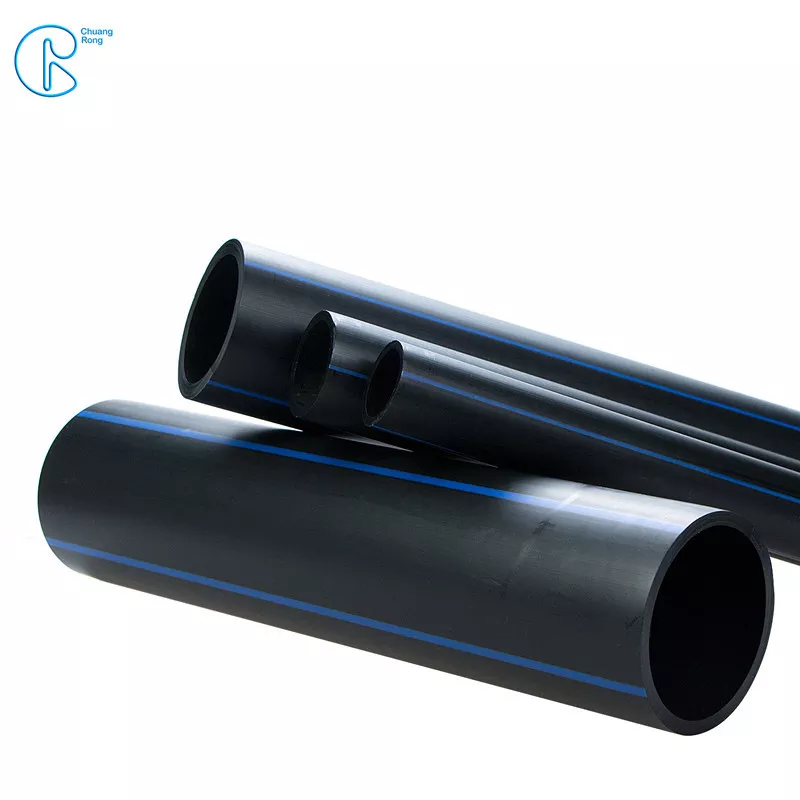

CHUANGRONG HDPE socket fittings are mainly used to connect OD20-110mm pipelines, and are used for water supply, gas, irrigation, etc. Socket welding principle: This method of connecting pipes and fittings involves a heating tool that can simultaneously heat plastic pipes and fittings to a melting point. In this case, the molten pipe can be melted by inserting it To connect the two in the socket of the accessory. Once properly inserted and allowed to cool, these two parts become a continuous bond of HDPE plastic, unable to separate and form a stronger connection than its parts.

CHUANGRONG manufactures a full line of HDPE socket fusion fittings, in which the outer diameter of the pipe is controlled over the entire thickness of the side wall. We offer stocks of the following socket welding sizes: OD20-110mm, 1/2 “, 3/4″, 1 “, 1 1/4″, 1 1/2 “, 2″.And comprehensive types: casing, elbow, tee, flange head, inner and outer wire fittings.

Specification

| SPECIFICATIONφD | QUANTITY(PC) | BOX SIZE(W×L×D)mm | Unit Volumn(cbm) | NW/CTN(KG) |

| 20×1/2“ | 250 | 47*31*17 | 0.025 | 28.25 |

| 25×3/4“ | 150 | 47*31*17 | 0.025 | 24.00 |

| 32×1“ | 100 | 47*31*17 | 0.025 | 23.20 |

| 40*11/4“ | 50 | 47*31*17 | 0.025 | 20.95 |

| 50*11/2“ | 40 | 47*31*17 | 0.025 | 27.80 |

| 63*2“ | 20 | 47*31*17 | 0.025 | 25.78 |

Adavantages

1.Customer-specific solutions

According to the specific needs of customers, we provide the most cost-effective solution. We produce custom parts that meet the requirements of all technical customers: we manufacture tubes of any contour and diameter.

2.Production process: injection molding

Safety, reliability and performance are ensured through the injection molding process used to make our accessories.

We use state-of-the-art technology to enable us to mold accessories with diameters up to 1200mm!

3.Eco-friendly and Safer Use: Non-toxic, no heavy metal additives

4.Impact Resistance

5.Low Temperature Resistance

6.Good Corrosion Resistance/Corrosion Resistance

7.Excellent Shock Resistance

8.Safe and Reliable Connection Method

Application

1.Municipal water supply, gas supply and agriculture etc.2.Commercial & Residential water supply3.Industrial liquids transportation4.Sewage treatment5. Food and chemical industry7. Replacement of cement pipes and steel pipes8. Argillaceous silt, mud transportation9. Garden green pipe networks

Certificaiton

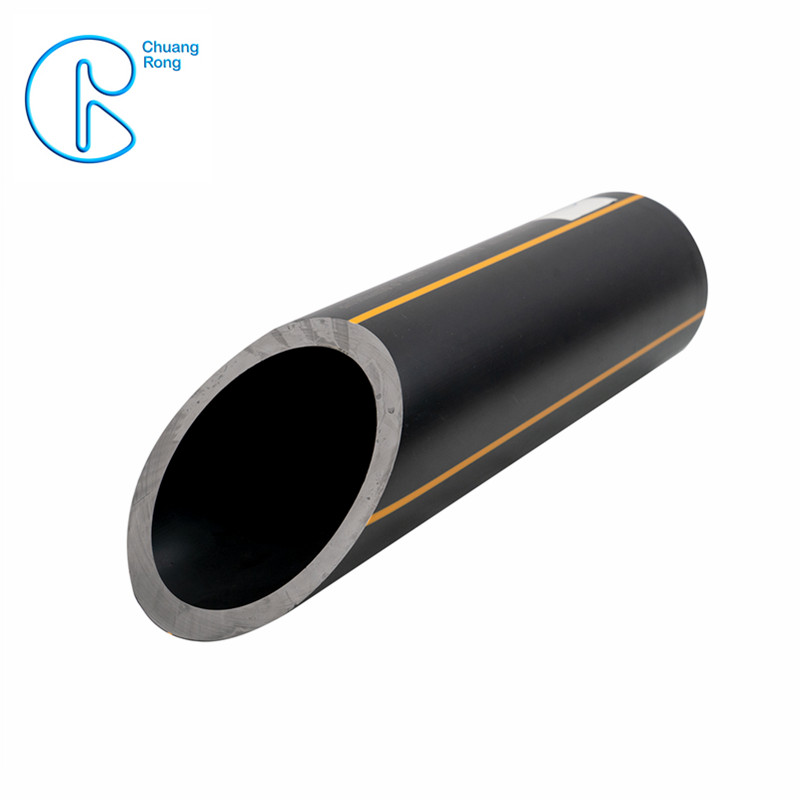

Product detail pictures:

Related Product Guide:

We attempt for excellence, support the customers", hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for China Wholesale Socket Fusion Fittings Pricelist – PE100 PN16 SDR11 HDPE Socket Fusion Fittings Female Thread Union For Municipal Water Supply – CHUANGRONG , The product will supply to all over the world, such as: Denmark, Nicaragua, Kenya, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top