Welcome To CHUANGRONG

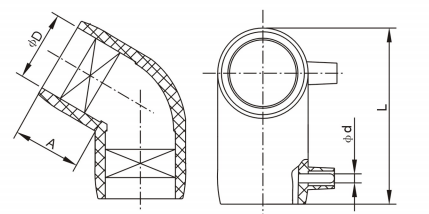

OEM/ODM HDPE EF Fittings Electrofusion HDPE 45 Degree Elbow

Detail Information

CHUANGRONG is a share industry and trade integrated company, established in 2005 which focused on the production of HDPE Pipes, Fittings & Valves, PPR Pipes, Fittings & Valves, PP compression fittings & Valves, and sale of Plastic Pipe Welding machines, Pipe Tools, Pipe Repair Clamp and so on.

CHUANGRONG can provide high quality HDPE Electrofusion Fittings for Water,Gas and Oil DN20-1200mm, SDR17, SDR11, SDR9 with bar code at competitive price.

PE100 Electrofusion 45 Degree Elbow For Water Gas and Oil Supply

|

Fittings Type |

Specification |

Diameter(mm) |

Pressure |

|

HDPE Electrofusion Fittings |

EF Coupler |

DN20-1400mm |

SDR17, SDR11 SDR9(50-400MM) |

|

EF Reducer |

DN20-1200mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF 45 deg elbow |

DN50-1000mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF 90 deg elbow |

DN25-1000mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF Tee |

DN20-800mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF Reducing Tee |

DN20-800mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF End Cap |

DN50-400mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF Stub End |

DN50-1000mm |

SDR17, SDR11 SDR9(50-400MM) |

|

|

EF Branch Saddle |

DN63-1600mm |

SDR17, SDR11 |

|

|

EF Tapping Saddle |

DN63-400mm |

SDR17, SDR11 |

|

|

EF Repair Saddle |

DN90-315mm |

SDR17, SDR11 |

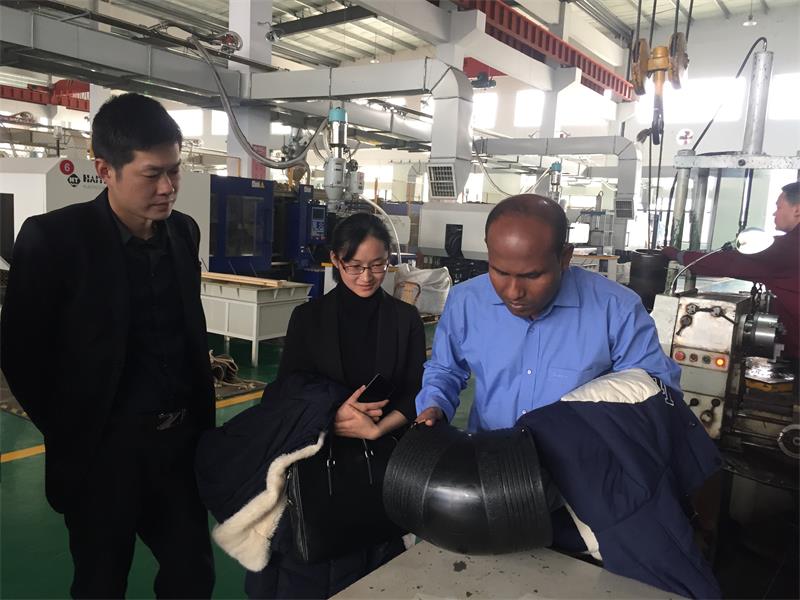

Welcome to visit our factory or conduct a third-party audit.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com

Product Description

45 degree Elbow Electrofusion HDPE Fittings for Water supply PN16 SDR11 PE100

1.Electrofusion HDPE fittings are welded by electrofusion machine to connect HDPE pipes together.

2. After electrofusion welding machine plug in electricity and turn on, The copper wire buried inserted in electric fuse.

3. HDPE fittings are heated and make HDPE melt, Which joint HDPE pipe and fittings well.

Pin

The pin provides a totally automatic methood for ensuring the correct welding parameters are used. Within each pin is a resiter. When hte electrofusion box is connected to the fitting, the pin enables it to automatically identify the correct fusion time required to make the joint. All the operator has to do is press go.

Indicators

The pressure created by the expanding molten plastic in the jointing area inside the fitting during the electrofusion process will force out the indicator lugs. This is a visible sign that the neccessary jointing pressure has been achieved.

Moulded -in welding parameters

Manual welding paarameters are moulded into the body all fitttings. Information provided includes fitings size, materail(PE80 OR PE110),applicable pipe SDRs, welding parameters, and pressure ratings for gas and water applicationgs.

Barcode

Quality control is central the success of fittings. The barcode provides full traceability right down to the polymer batch, the raw material from which the fititngs are manufactured for each individual fittings. The barcode also carries the welding parameters for us withe electrofusion boxes equipped with a barcode scanner. The new QR code on alll fittings illustrate full traceability on each individual fitting that reaches the consumer.

| Product Name: | 45 Degree Elbow Electrofusion HDPE Fittings For Water Supply PN16 SDR11 PE100 | Material: | PE100 Virgin Raw Material |

|---|---|---|---|

| Standard: | EN 12201-3:2011,EN 1555-3:2010 | Application: | Gas,Water,Oil Etc |

| Specification: | OD50-1000mm | Port: | China Main Port |

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

|

specifications φD |

L mm |

A mm |

Φd mm |

|

50×45° |

130 |

50 |

4.7 |

|

63×45° |

180 |

63 |

4.7 |

|

90×45° |

230 |

83 |

4.7 |

|

110×45° |

270 |

90 |

4.7 |

|

160×45° |

280 |

85 |

4.7 |

|

200×45° |

330 |

100 |

4.7 |

|

250×45° |

420 |

115 |

4.7 |

|

315×45° |

470 |

130 |

4.7 |

|

400×45° |

580 |

140 |

4.7 |

|

450×45° |

587 |

145 |

4.7 |

|

500×45° |

587 |

151 |

4.7 |

|

560×45° |

735 |

180 |

4.7 |

|

630×45° |

735 |

185 |

4.7 |

CHUANGRONG and its affiliated companies specialize in the R&D, production, sale and installation of new-type plastic pipes and fittings. It owned five factories, one of the largest manufacturer and supplier of plastic pipes and fittings in China. Furthermore, the company owns more 100 sets pipe production lines that are advanced at domestic and abroad,200 sets of fitting production equipment. The production capacity reaches more than 100 thousand tons. Its main contain 6 systems of water, gas, dredging, mining, irrigation and electricity, more than 20 series and more than 7000 specifications.

| TEST ITEMS | RESULT | CONCLUSION | |||

| APPEARANCE | THE INNER AND OUTER SURFACES OF THE FITTINGS SHOULD BE CLEAN,SMOOTH AND WITHOUT AIR HOLES,SHRINK PIT,OBVIOUS SCRATCHES AND OTHER SURFACE DEFECTS.PIPE FITTINGS SHOULD BE COMPLETE WITHOUT DEFECTS,GATES AND OVERFLOW SHOULD BE REMOVE | QUALIFIED | |||

| SOCKET FITTING OR ELECTRO FUSION SOCKET END | AVERAGE OD MM | / | QUALIFIED | ||

| WALL THICKNESS MM | / | QUALIFIED | |||

| OUT OF ROUNDNESS MM | / | QUALIFIED | |||

| TUBULAR LENGTH MM | / | QUALIFIED | |||

| ELECTRO FUSION FITTING BELL END | AVERAGE ID MM | MORE THAN 160 | QUALIFIED | ||

| FUSION AREA LENGTH MM | MORE THAN 20 | QUALIFIED | |||

| DEPTH OF SOCKET MM | 68-98 | QUALIFIED | |||

| OUT OF ROUNDNESS MM | LESS THAN 2.4 | QUALIFIED | |||

| ELECTRICAL PERFORMANCE OF ELECTRO FUSION FITTING | 23℃MAX:nominal x (1+10%)+0.1ΩMIN: nominal x (1-10%) | QUALIFIED | |||

| PYYSICAL AND MECHANICAL PROPERTIES | OXIDATION INDUCTION TIME (200℃) MIN | MORE THAN 20 | QUALIFIED | ||

| HYDROSTATIC STRENGTH | 80℃/,RING STRESS 5.4Mpa,DAMAGE TIME≥165h,NO BREAK,NO LEAK | ||||

| INSPECTION CONCLUSION | THE SAMPLING PIPE FITTING IS INSPECTED ACCORDING TO THE REQUIREMENT OF CHINA STANDARD GB/T 15558.2-2005 “PART 2” PIPE OF BURIED POLYETHYLENE (PE) PIPELINE SYSTEM FOR PIPES OF GAS:”PIPE FITTING”.THE RESULTS ARE COMPLY WITH THE STANDARD’S REQUIREMENT(GB/T 15558.2-2005 “PART 2” IS SAME AS EN1555-3:2010 ) | ||||

1.Municipal water supply, gas supply and agriculture etc.

2.Commercial & Residential water supply

3.Industrial liquids transportation

4.Sewage treatment

5. Food and chemical industry

6. Replacement of cement pipes and steel pipes

7. Argillaceous silt, mud transportation.

8. Garden green pipe networks

We can supply ISO9001-2015, BV ,SGS, CE etc certification. All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top