Welcome To CHUANGRONG

100% PE100 Virgin Material ISO / ASTM Standard Dn 50-1200mm Injection HDPE Butt Fusion Equal Tee

Detail Information

CHUANGRONG's mission is providing different customers with perfect one-stop solution for plastic pipe system. It can supply professionally designed, customized service for your project.

ISO / ASTM Standard Dn 50-1200mm Injection HDPE Butt Fusion Equal Tee

|

Type |

Specification |

Diameter(mm) |

Pressure |

|

HDPE Butt Fusion Fittings |

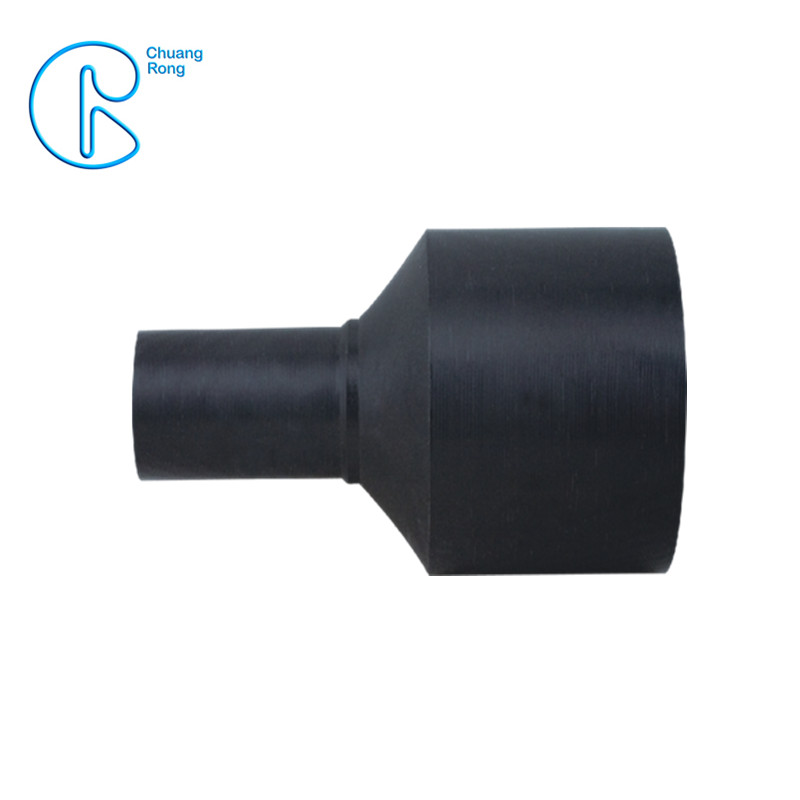

Reducer |

DN50-1200mm |

SDR17,SDR11, SDR9(90-400mm) |

|

Equal Tee |

DN50-1200mm |

SDR17,SDR11, SDR9(90-400mm) |

|

|

Reducing Tee |

DN50-1200mm |

SDR17,SDR11, SDR9(90-400mm) |

|

|

Lateral Tee(45 deg Y Tee) |

DN63-315mm |

SDR17,SDR11, SDR9(90-400mm) |

|

|

22.5 Deg Elbow |

DN110-1200mm |

SDR17,SDR11, SDR9(90-400mm) |

|

|

30 Deg Elbow |

DN450-1200mm |

SDR17,SDR11, SDR9(90-400mm) |

|

|

45 Deg Elbow |

DN50-1200mm |

SDR17,SDR11, SDR9(90-400mm) |

|

|

90 Deg Elbow |

DN50-1200mm |

SDR17,SDR11, SDR9(90-400mm) |

|

|

Cross Tee |

DN63-1200mm |

SDR17,SDR11, SDR9(90-400mm) |

|

|

Reducing Cross Tee |

DN90-1200mm |

SDR17,SDR11, SDR9(90-400mm) |

|

|

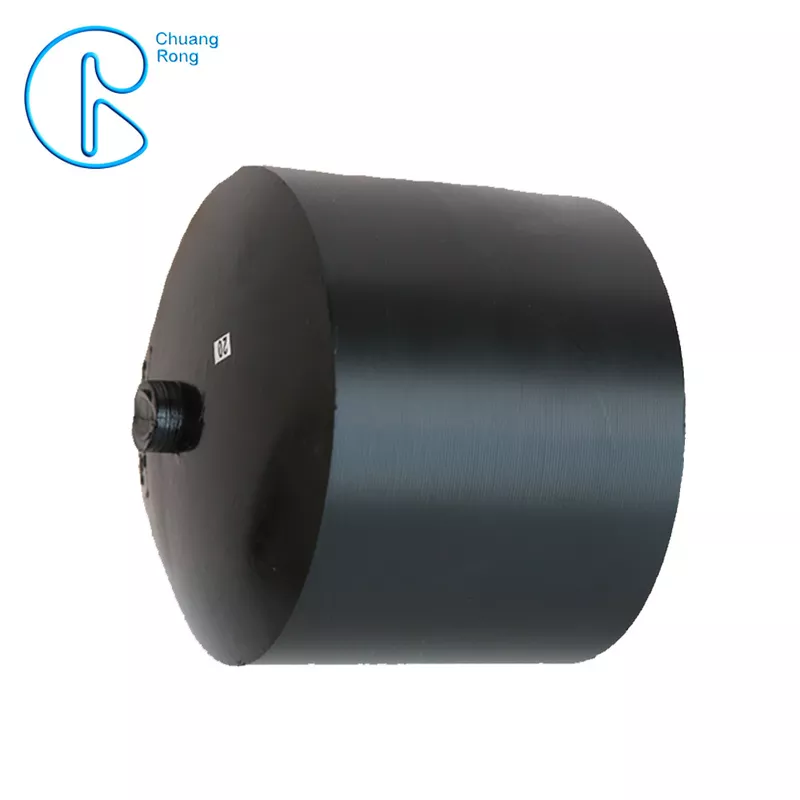

End Cap |

DN20-1200mm |

SDR17,SDR11, SDR9(90-400mm) |

|

|

Stub End |

DN20-1200mm |

SDR17,SDR11, SDR9(90-400mm) |

|

|

Male(Female) Union |

DN20-110mm 1/2'-4' |

SDR17,SDR11 |

Welcome to visit our factory or conduct a third-party audit.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com

Product Description

China Made Hdpe Fusion Dn 50-1200mm Equal Tee Buttweld Fittings

To date, butt welding is the most common method of joining polyethylene pipes of all diameters.

The ends of the polyethylene tubes are combined with the special equipment under pressure after heating to form a continuous “leak-proof” pipe. A properly fabricated tube cage is as strong as the tube itself and has the same life expectancy.

| Material: | 100% Virgin Material PE100 | Specification: | Dn50-Dn1200mm |

|---|---|---|---|

| Standard: | ISO4427/4437, DIN8074/8075 | Application: | Connection |

| Port: | NIngbo,Shanghai,Dalian Or As Required | Type: | Equal Tee |

CHUANGRONG has an excellent staff team with rich experience. Its principal is Integrity, Professional and Efficient. It has established business relationship with more than 80 countries and zones in relative industry. Such as United States, Chile, Guyana, The United Arab Emirates, Saudi Arabia, Indonesia, Malaysia,Bangladesh, Mongolia, Russia, Africa and so on.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

|

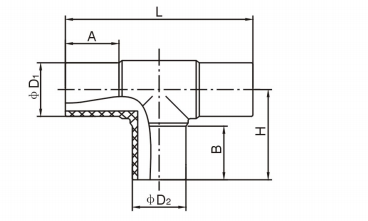

Specifications ΦD1×φD2×D1 |

L mm |

A mm |

B mm |

H mm |

|

50×50×50 |

170 |

55 |

55 |

82 |

|

63×63×63 |

200 |

63 |

63 |

104 |

|

75×75×75 |

230 |

70 |

70 |

114 |

|

90×90×90 |

260 |

79 |

79 |

133 |

|

110×110×110 |

290 |

82 |

82 |

145 |

|

125×125×125 |

315 |

87 |

87 |

160 |

|

140×140×140 |

345 |

92 |

92 |

170 |

|

160×160×160 |

325 |

75 |

75 |

170 |

|

180×180×180 |

420 |

105 |

105 |

225 |

|

200×200×200 |

377 |

75 |

84 |

200 |

|

225×225×225 |

484 |

120 |

120 |

230 |

|

250×250×250 |

517 |

120 |

120 |

265 |

|

280×280×280 |

590 |

140 |

140 |

300 |

|

315×315×315 |

615 |

130 |

125 |

310 |

|

355×355×355 |

630 |

120 |

120 |

350 |

|

400×400×400 |

670 |

120 |

120 |

360 |

|

450×450×450 |

805 |

150 |

175 |

430 |

|

500×500×500 |

855 |

150 |

180 |

485 |

|

560×560×560 |

910 |

145 |

180 |

525 |

|

630×630×630 |

990 |

145 |

180 |

530 |

|

710×710×710 |

1140 |

150 |

190 |

565 |

|

800×800×800 |

1260 |

150 |

190 |

610 |

CHUANGRONG and its affiliated companies specialize in the R&D, production, sale and installation of new-type plastic pipes and fittings. It owned five factories, one of the largest manufacturer and supplier of plastic pipes and fittings in China. Furthermore, the company owns more 100 sets pipe production lines that are advanced at domestic and abroad,200 sets of fitting production equipment. The production capacity reaches more than 100 thousand tons. Its main contain 6 systems of water, gas, dredging, mining, irrigation and electricity, more than 20 series and more than 7000 specifications.

(1) Non-toxic: HDPE pipe material is nontoxic and tasteless pipe which belongs to green building materials. No heavy metal additives would not be covered with dirt or contaminated by bacterium.

(2) Good chemical corrosion resistance: HDPE is resistant to the corrosion of various chemical media, and the presence of chemical substances in the pipe will not cause any degradation effect.

(3) Long service life: HDPE contains 2% to 2.5% carbon black polyethylene, and the service life is more than 50 years.

(4) Higher Flow Capacity:smooth interior walls result in lower pressure loss and higher volume than metal pipe.

(5) Lower Installation Costs:light weight and ease of installation can reduce installation costs by as much as 33% over metal piping system.

(6) Recycled and Environment-friendly.

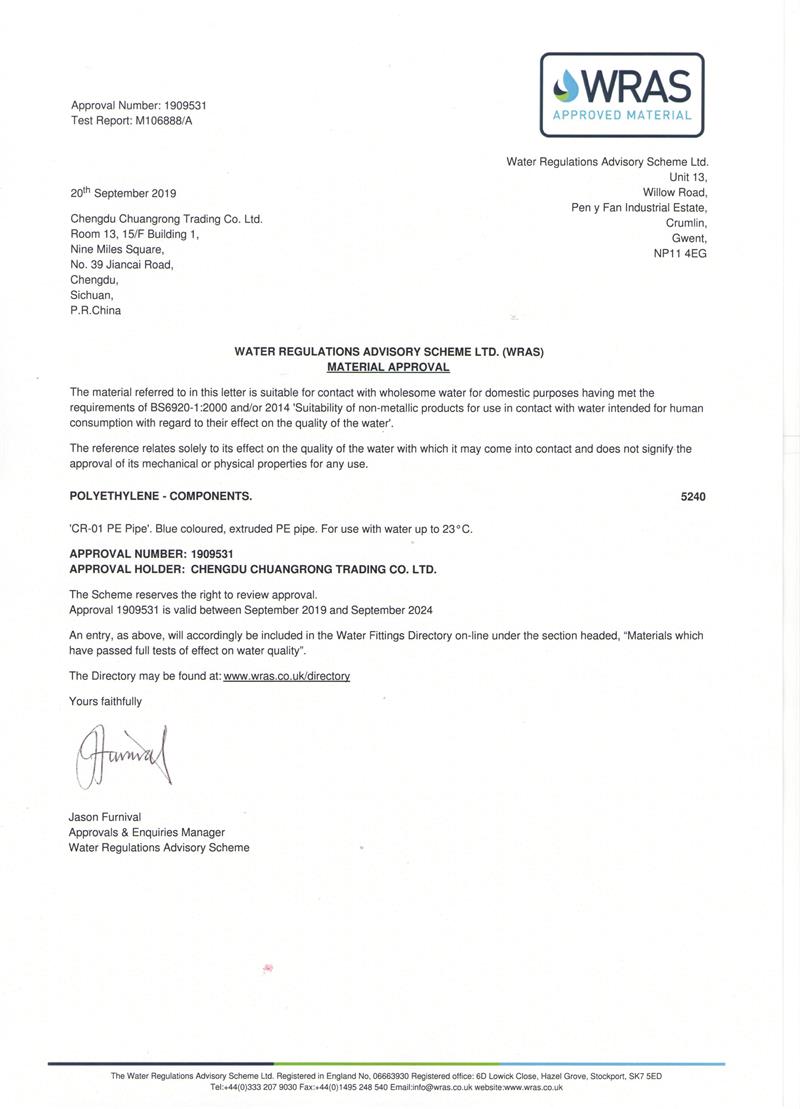

CHUANGRONG possesses complete detection methods with all kinds of advanced detection equipment to ensure the quality control in all processes from raw material to finished product. The products are in line with ISO4427/4437, ASTMD3035, EN12201/1555, DIN8074, AS/NIS4130 standard, and approved by ISO9001-2015, CE, BV, SGS, WRAS.

-Potable water mains, service pipes and house connections

-Gas transmission, distribution and house comnections.

-Wastewater systems including sewers.

-Water and wastewater treament plants.

-Rain water and grey water collection.

-Syphonic roof drainage.

-Trenchless pipeline techniques including directional drilling.

-Pumped sluury systems in mines and quarries.

-Ducting for electrical, telecomumunications and fibre optic cabling including subsea.

-Open water and marine fish cages.

-Industrial applications including process pipework and compressed air networks

-Agricultural irrigation

……and many more

Melt Flow Rate(MFR)-in according with the methodology specified in EN ISO1130.

Oxidation induction Time(OIT)test -in according with the methodology specified in EN ISO11357-6.

Resistance to internal pressure at constant temperature in accordance with the methodology specified in EN1167

-Test temprature 20℃-100h

-Test temprature 80℃-165h

-Test temprature 80℃-1000h

Verification of mechanical welding characteristics:yield stress,tear decohesion, crushing decohesion. Testing methods in accordance with the methodology specified in ISO13953.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top