Welcome To CHUANGRONG

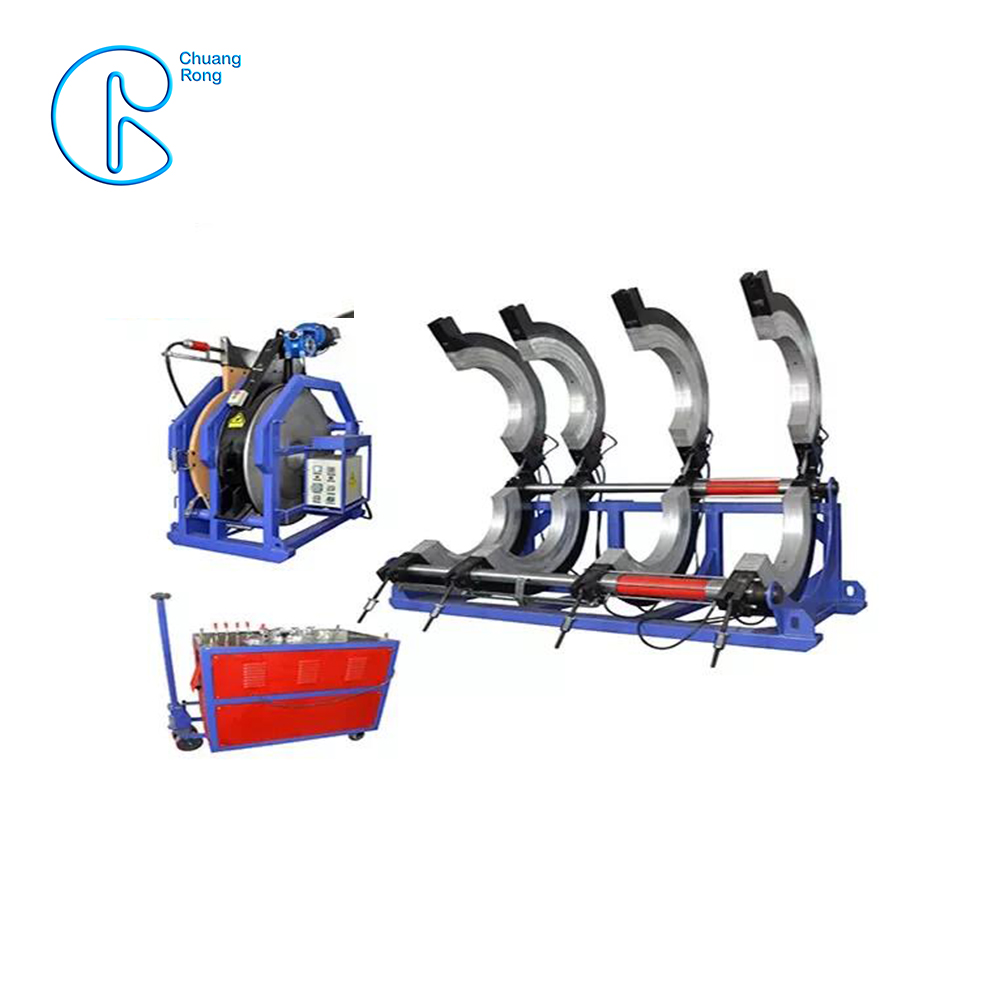

HDPE Plastic Pipe DN1200mm / DN1600mm Butt Fusion Welding Machine With Crane

Basic Information

CHUANGRONG is a share industry and trade integrated company, established in 2005 which focused on the production of HDPE Pipes, Fittings & Valves, PPR Pipes, Fittings & Valves, PP compression fittings & Valves, and sale of Plastic Pipe Welding machines, Pipe Tools, Pipe Repair Clamp and so on.

Plastic Pipe DN1200mm / DN1600mm Butt Fusion Welding Machine

| Condition: | New | Working Range: | 800-1200/1200-1600 |

|---|---|---|---|

| Usage: | Pipe Fittings Welding | Warranty: | 1 Year |

| Materials: | HDPE,PP,PVDF | The Heating Plate Temperature: | 170-250(±5℃)MAX270℃ |

Product Description

Electric Cutter 1200MM / 1600MM Pipe Welding Machine With Crane

1200MM / 1600MM Pipe Welding Machine Description

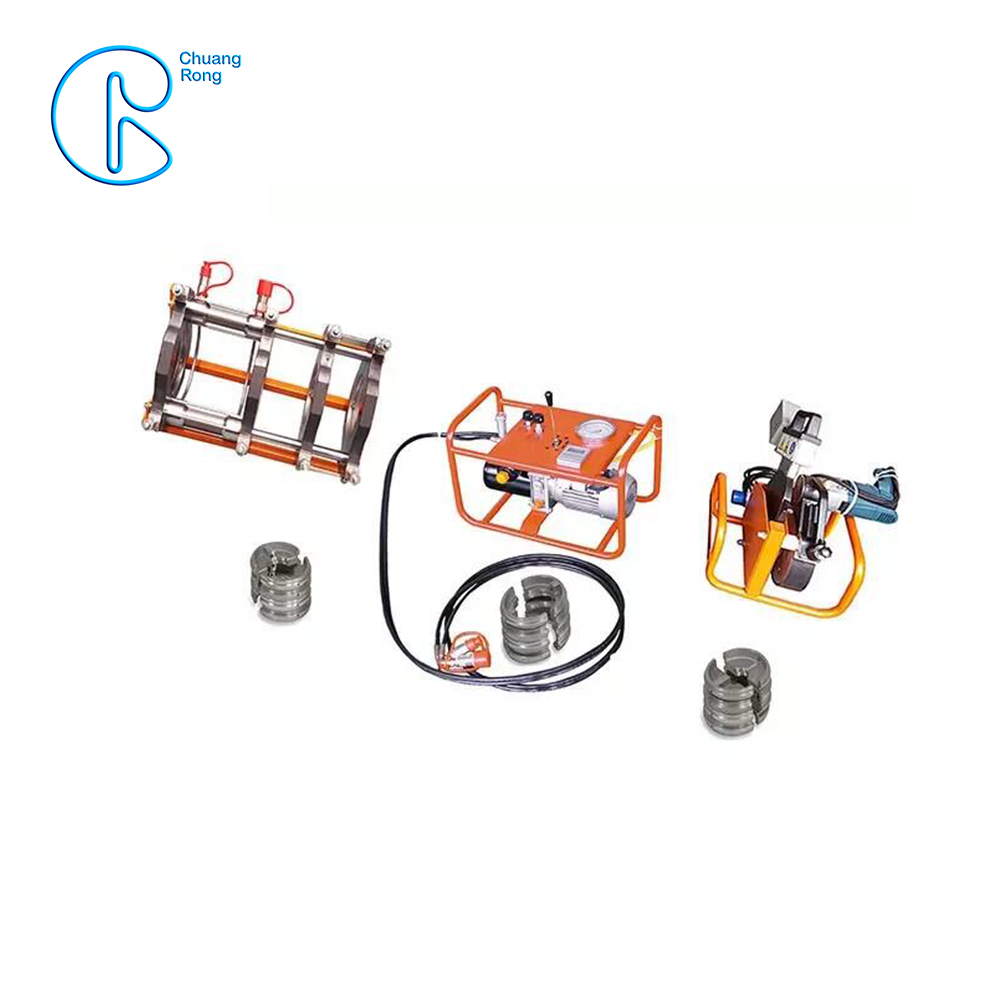

This is a self-aligning welding machine with hydraulic clamps suitable for welding HDPE pipes for the transport of water and other fluids under pressure, up to DN1600mm.

The CRDH 1600 is designed in accordance to international standards(UNI10565,ISO12176-1). The CRDH1600 can weld fitings such as elbows,tees, branches and flange necks.

CHUANGRONG has an excellent staff team with rich experience. Its principal is Integrity, Professional and Efficient. It has established business relationship with more than 80 countries and zones in relative industry. Such as United States, Chile, Guyana, The United Arab Emirates, Saudi Arabia, Indonesia, Malaysia,Bangladesh, Mongolia, Russia, Africa and so on.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

| Model | CRDH 1200 | CRDH 1600 |

| Range(mm) | 800/900/1000/1100/1200 | 1200/1400/1600 |

| Type | Elbow,90 degree equal tees,cosses,Equal Branch Tee and Wye Tee | |

| The Heating Plate Temperature | 170℃-250℃(±7℃)Max270℃ | 170℃-250℃(±7℃)Max270℃ |

| Power Supply | 36.5KW | 59KW |

| Total Weight | 1800kg | 2500kg |

| Optional Accessory | Stub end holder and special inserts | |

-Robust machine body made of steel. The main body supportsa and centres the plastic pipes with two fixed and two movable clamps.

-Steel hydraulic clamping. The necessary electric will be transfered to the heater and milling cutter by means of this unit and to the main machine by the hydraulic pressure.

-Automotic detaching device of heating plate. The pipe ends wiil be heater before the welding process. The setting of the heater wiil be done by the thermostat on the plates. butt welding machine PTFE-coated heating element and uniform surface temperature.

-Raised platform deck for perfect monitoring of fusion process

-Easy to operate control panel.

-The data-logging compatible

-On board hydraulic control gearcase

-Pressure adjustment and pressure release valves for easy operations

-Hydraulically controller facer with safety microswitch

-Teflon coated heating plate with indipengdent tehrmometer

-From the rack, cutter, independent heating plates and bracket-Frame made of high strength materials and structures, 45 ℃ tilt design-Electric cutter, safety limit switch to prevent accidental start-cutter

| CRDH 1200 | Body+ Hydraulic 2970*1980*2080 | 12.23 | 1972 | 2368 | |

| Frame 1880*1170*2360 | 5.19 | 1107 | 1297 | ||

| Total | 17.42 | 3079 | 3665 | 2 cases | |

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top