Welcome To CHUANGRONG

Factory best selling 3.5kw Electrofusion HDPE Pipe Fitting Welding Machine/Electro Fusion Welder/ Butt Fusion Machine/Inverter PE Electrofusion Fittings Welding Machine/

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for Factory best selling 3.5kw Electrofusion HDPE Pipe Fitting Welding Machine/Electro Fusion Welder/ Butt Fusion Machine/Inverter PE Electrofusion Fittings Welding Machine/, We warmly welcome clients, enterprise associations and mates from all over the globe to speak to us and find cooperation for mutual rewards.

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for China Electrofusion Welding Machine and Butt Fusion Welding Machine, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of “human-oriented and faithful service”, with an aim to gain global recognition and sustainable development.

Basic Information

Standard composition

1.Machine body

2.Milling cutter

3.Heating plate

4.Hydraulic control unit

5.Support

6.Clamps

| Product Name: | Automatic Welding Machine | Working Range: | 160-355/250-400/315-500/400-630MM |

|---|---|---|---|

| Usage: | Pipe Fittings Welding | Warranty: | 1 Year |

| Single Phase: | 50/60Hz | Protection Level: | IP54 |

Product Description

Application

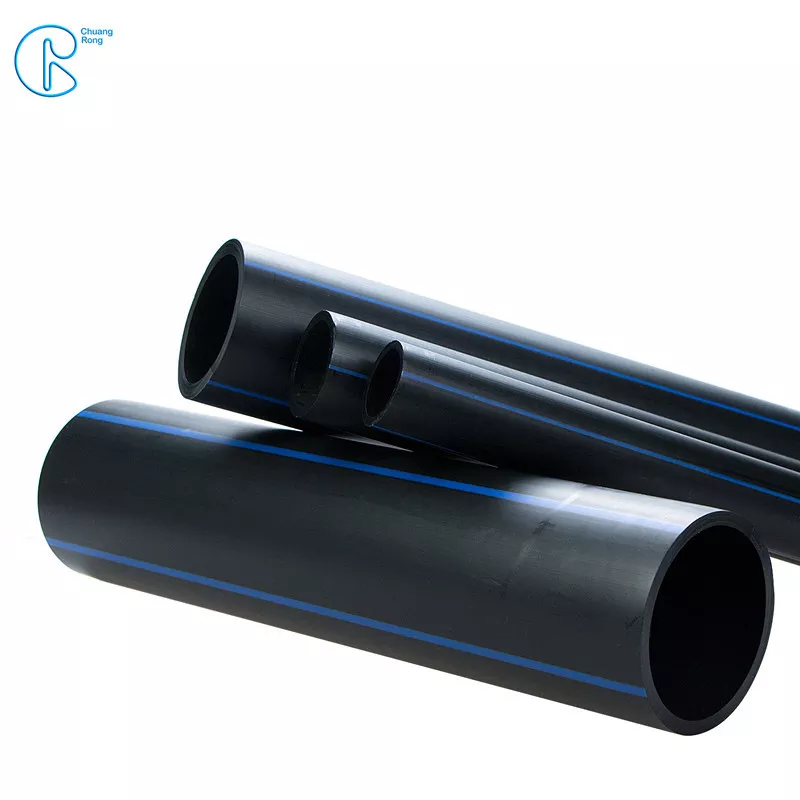

CNC is an on-site butt welding machine for pipes and fittings in Polyethylene (PE), Polypropylene (PP), and other thermoplastic materials intended for the transport of water under high pressure.

We remind you that the use of such machines is limited to authorized skilled and certified personnel, in accordance with the Legislation and Regulations in force.

Viewing and downloading

Click the Data Query button to enter the welding data management screen.

Features

| GENERAL | 160 | 250 | 315 |

| Working range: | Ø 63 ÷ Ø 160 mm | Ø 75 ÷ Ø 250 mm | Ø 90 ÷ Ø 315 mm |

| Materials: |

HDPE, PB, PP, PVDF |

||

| Range of ambient temperatures: |

-10 ÷ +40 °C |

||

| Power supply: |

230 VAC 50-60 Hz |

||

| Nominal power | 2600 W | 3950 W | 4950 W |

| Pressure’s working range: |

Up to150 bar |

||

| Weight | 80 Kg | 144 Kg | 194Kg |

| Welding cycle |

Automatic |

||

| Memory capacity |

4000 stored weldings |

||

| Transfer of stored data |

pdf document on USB flash drive |

||

| Barcode traceability | Pipe/Fitting upon ISO 12176-4Operator upon ISO 12176-3 | ||

| GPS |

Enabled |

||

| Noise (dBA) |

LpA = 74 dBA |

||

| Chassis | 160 | 250 | 315 |

| Overall thrust section: | 9.42 | 10.99 cm2 | 12.56 cm2 |

| Dimensions: [ W×D×H ] | 600x400x410 [mm] | 960x650x950 [mm] | 1090 x 800 x 1100 [mm] |

| Weight: | 35 Kg | 66 Kg | 150 Kg |

| Facer | 160 | 250 | 315 |

| Nominal power | 800 W | 900 W | 900W |

| Dimensions: [ W×D×H ] | 430×330×80 [mm] | 440×450×380 [mm] | 600×460×390 [mm] |

| Weight: | 7.5 Kg | 15 Kg | 21 Kg |

| Heater | 160 | 250 | 315 |

| Nominal power | 1000W | 2000W | 3000W |

| Dimensions: [ W×D×H ] | 350×50×450 [mm] | 470×50×490 [mm] | 470×50×600 [mm] |

| Weight: | 3.6 Kg | 8 Kg | 13 Kg |

| Facer/heater holder | 160 | 250 | 315 |

| Dimensions: [ W×D×H ] | 300×370×440 [mm] | 380×265×600 [mm] | 590×315×650 [mm] |

| Weight: | 3.5 Kg | 10 Kg | 16 Kg |

| Hydraulic gearcase | |||

| Nominal power |

1100 W |

||

| Pressure range: |

up to 150 bar |

||

| Hydraulic oil: | Viscosity class 46 o 68 ISO 3448Recommended :- TEXACO RANDO HDZ 46- ESSO UNIVIS N 46- SHELL TELLUS T 46 | ||

| INSERT DIAMETER (welght [kg] full set) | 160 | 250 | 315 |

| Ø 63mm | 2.6 | 8.4 | |

| Ø 90 mm | 2.3 | 8.0 | 16.0 |

| Ø 110 mm | 2.1 | 7.5 | 15.5 |

| Ø 160 mm | 6.0 | 14.0 | |

| Ø 200 mm | 4.8 | 12.5 | |

| Ø 250 mm | 10.5 | ||

| On request | Ø 75/125/140mm | Ø 75/125/140/180/225mm | Ø 125/140/180/225/280mm |

SAFETY CRITERIA

The use of the of this product is intended exclusively to qualified personnel according to the standards in force.

Use the machine only for purposes as described on “Fields of Application” and according to the operator’s manual. Any other use is forbidden, since it may cause harm to persons, damage the machine or other objects.

Do not remove the safety devices (switches, micro-switches, seals, etc).

Replace defective or worn out parts only with Original spare parts.

Any intervention or repair on the machine has to be performed by qualified personnel.Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for Factory best selling 3.5kw Electrofusion HDPE Pipe Fitting Welding Machine/Electro Fusion Welder/ Butt Fusion Machine/Inverter PE Electrofusion Fittings Welding Machine/, We warmly welcome clients, enterprise associations and mates from all over the globe to speak to us and find cooperation for mutual rewards.

Factory best selling China Electrofusion Welding Machine and Butt Fusion Welding Machine, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of “human-oriented and faithful service”, with an aim to gain global recognition and sustainable development.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top