Welcome To CHUANGRONG

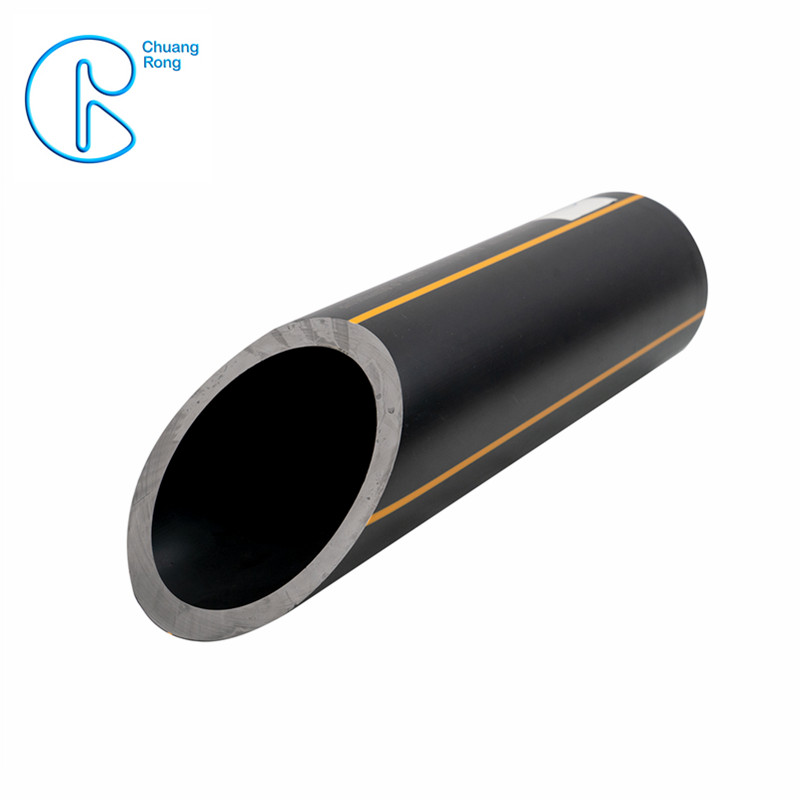

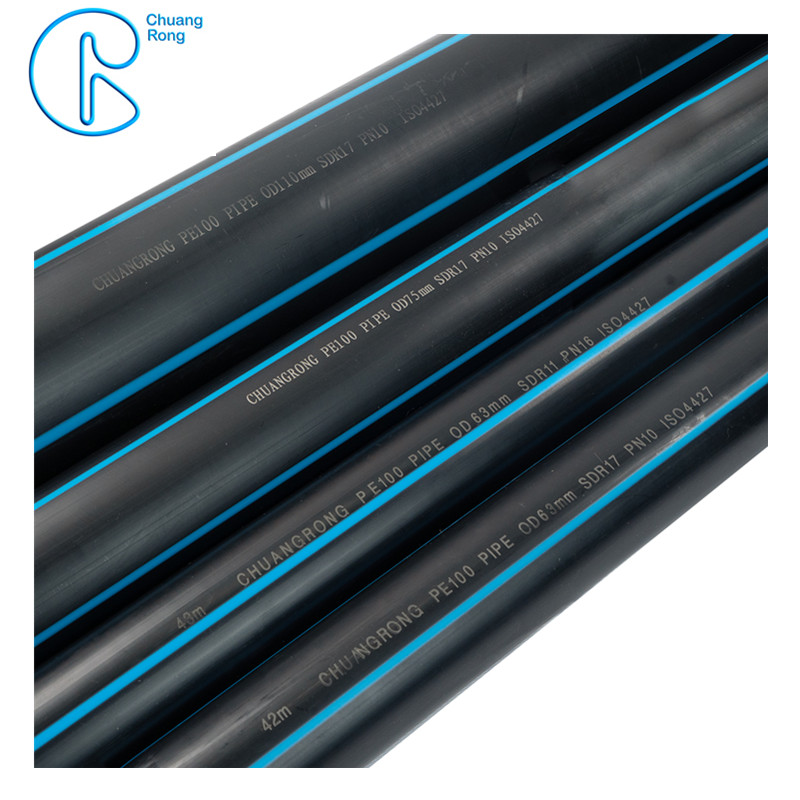

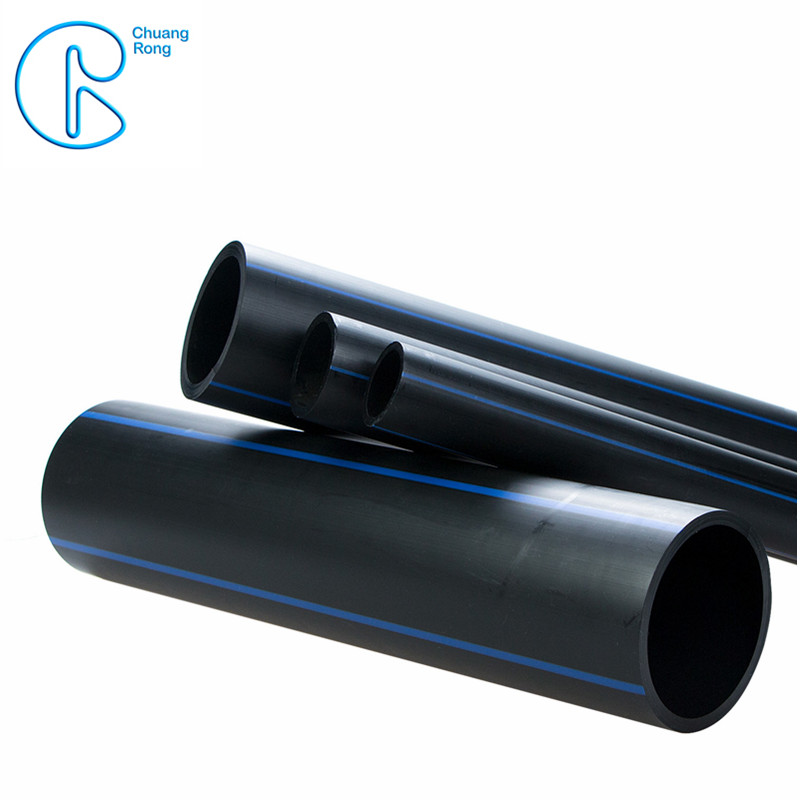

Polythylene PE80 /PE100/ MDPE Pipe For Natural Gas & Oil Pipe System

Basic Information

CHUANGRONG is a share industry and trade integrated company, established in 2005 which focused on the production of HDPE Pipes, Fittings & Valves, PPR Pipes, Fittings & Valves, PP compression fittings & Valves, and sale of Plastic Pipe Welding machines, Pipe Tools, Pipe Repair Clamp and so on.

Polythylene PE80 /PE100/ MDPE Pipe For Natural Gas & Oil Pipe System

| Products Details | Company/Factory Strength | ||

| Name | Polythylene Pipe For Natural Gas & Oil Pipe System | Production Capacity | 100,000 Ton/Year |

| size | DN20-630mm | Sample | Free sample available |

| Pressure | SDR17.6 PE80 5Bar/PE100 6BaSDR11 PE80 7Bar/PE100 10Bar | Delivery time | 3-15 days, depending on the quantity |

| Standards | ISO4437, EN1555, GB15558 | Test/inspection | National standard laboratory, Pre-delivery inspection |

| Raw Material | 100% Virgin PE80, PE100, PE100-RC | Certificates | ISO9001, CE, WRAS, BV, SGS |

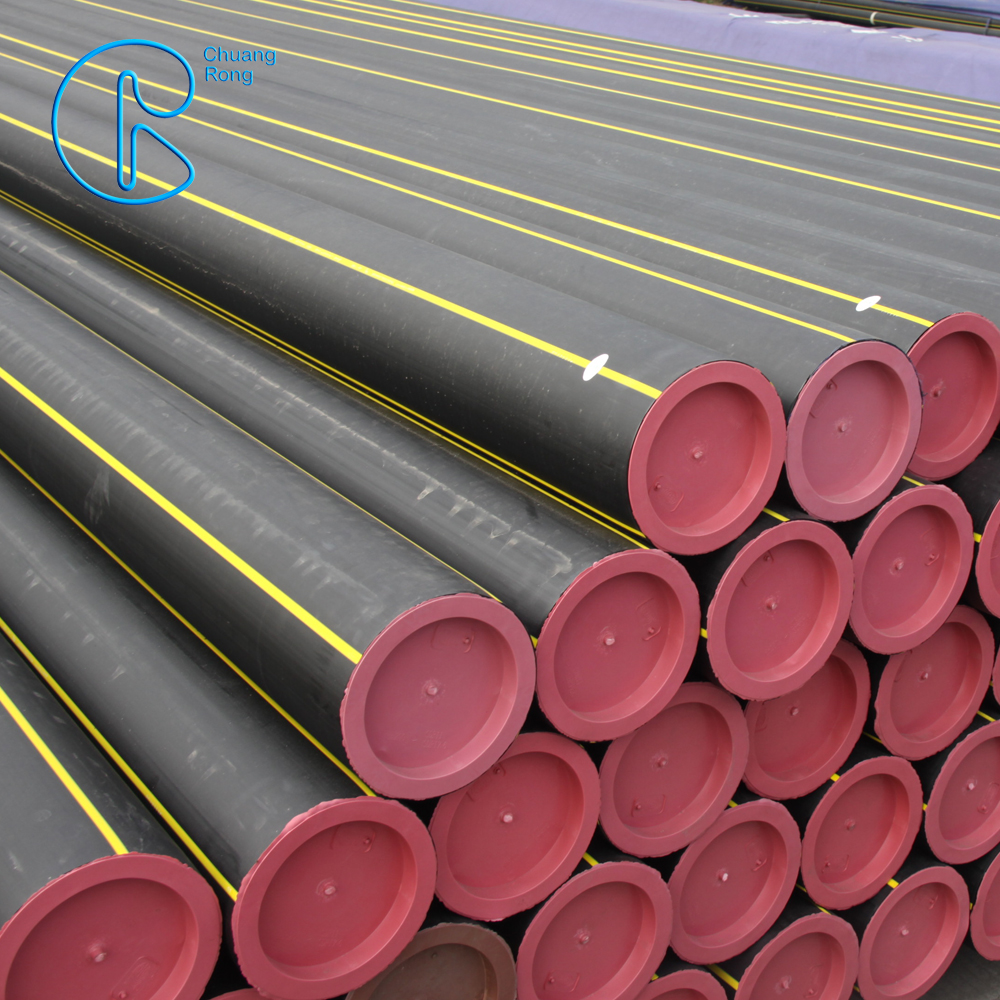

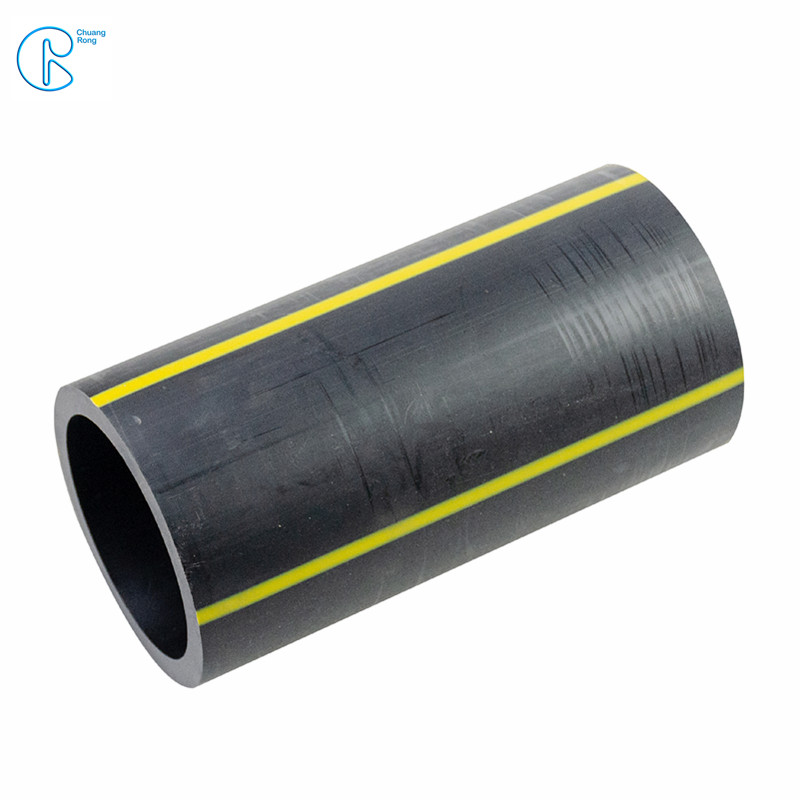

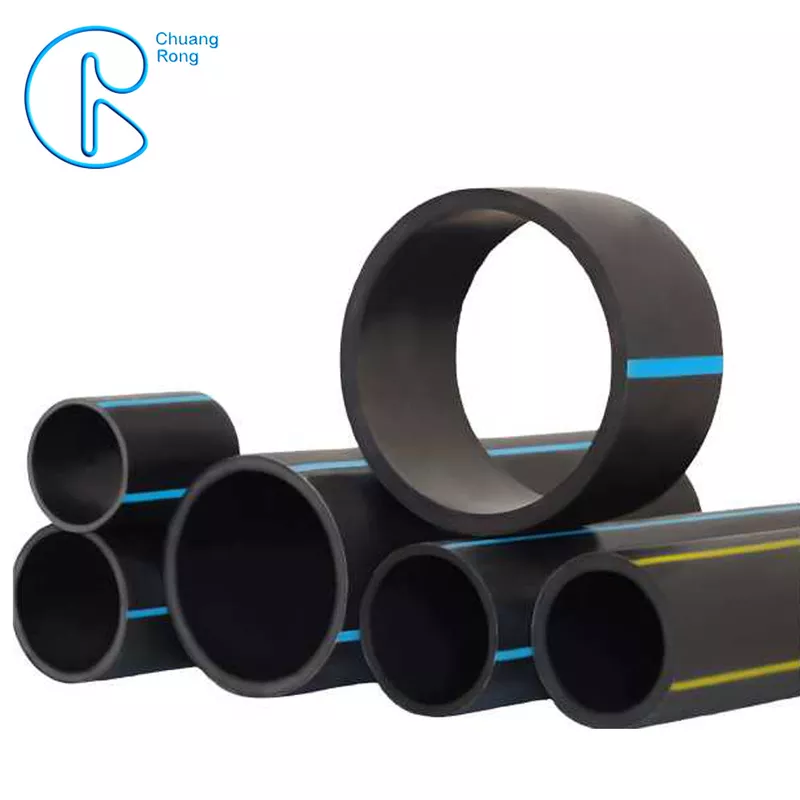

| Color | Black with Yellow stripe, Yellow or others colors | Warranty | 50 years with normal use |

| Packing | 5.8m or 11.8m/length, 50-200m/roll, for DN20-110mm. | Quality | QA & QC system, Ensure traceability of each process |

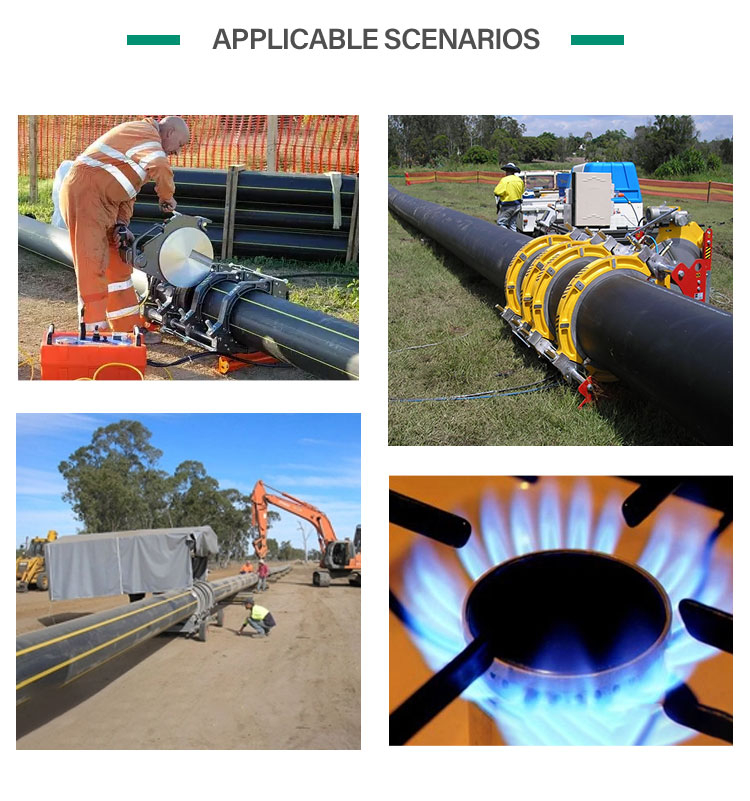

| Application | Oil and Gas | Service | R&D, production, sale and installation, after-sales service |

| Matching products: Butt fusion, Socket fusion, Electrofusion, Drainage, Fabricated, Machined fitting, Compression fittings, Plastic Welding machines and tools, etc. | |||

Welcome to visit our factory or conduct a third-party audit.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com

Product Description

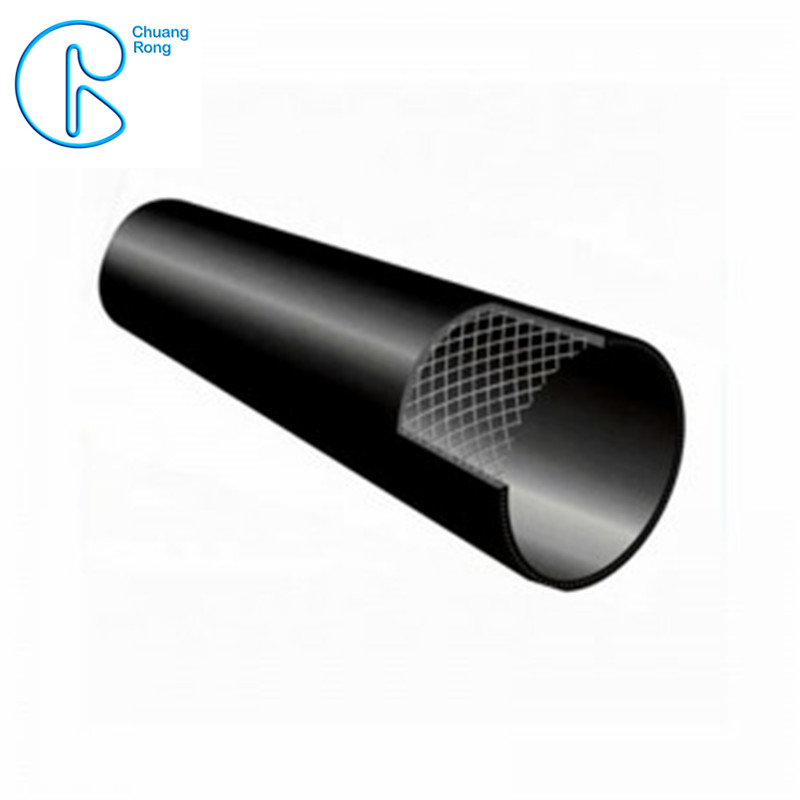

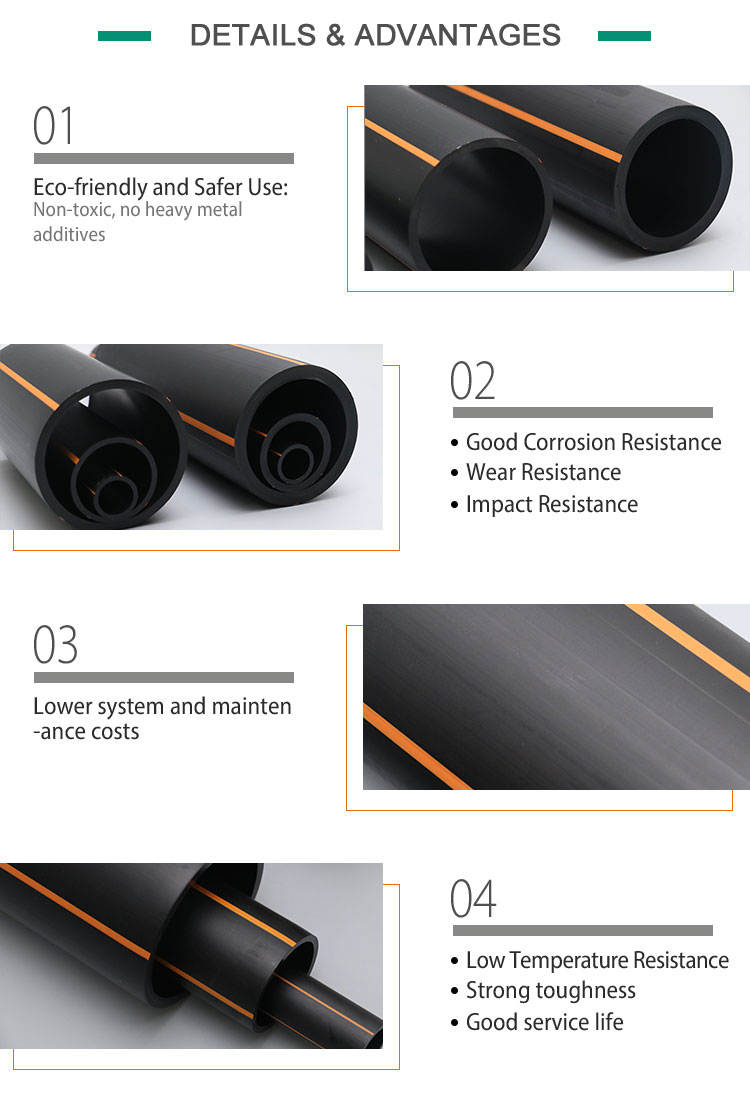

CHUANGRONG offer a complete piping system manufactured in Medium(High) Density Polyethylene for low pressure gas transport applications and distribution of natural gas or LPG.

Meet ISO4437 /EN1555 and has achieved CE&BV&ISO&BECETEL(BELGIAN RESEARCH CENTRE FOR PIPES AND FITTINGS)&SP.

The advantages of the PE pipe have been approved in the Gas Industry. Polyethylene’s toughness & light-weightiness adds to its cost effective and reliable solutions required for Gas Distribution Systems.

CHUANGRONG Polyethylene Gas Pipes are available in the range of 20 mm to 630 mm O.D.

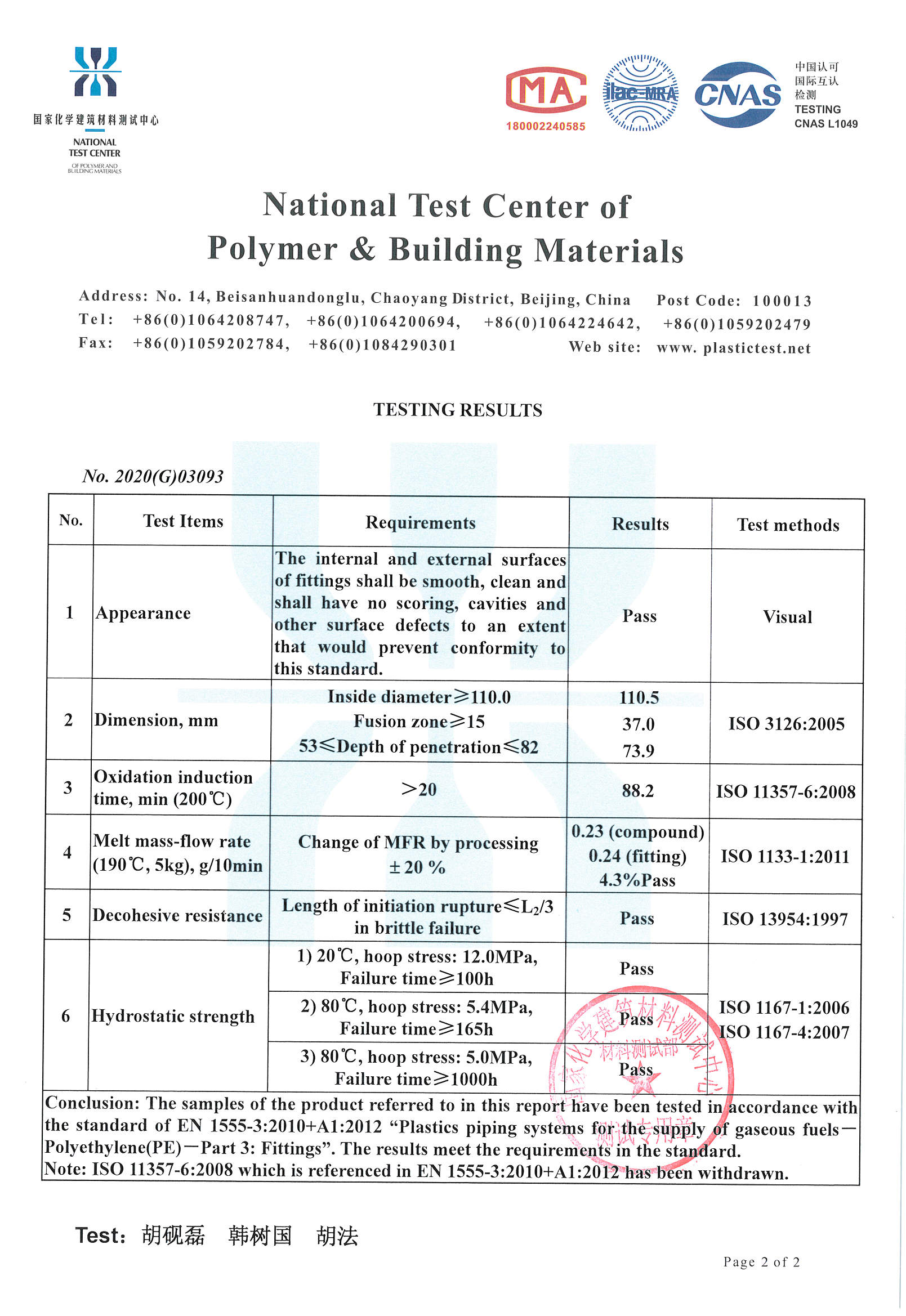

Polyethylene Gas pipe Test Properties:

|

Appearance Requirement |

|||||

|

Appearance

|

The inner and outer surfaces of the pipe should be clean and smooth, and no bubbles, obvious scratches, dents, impurities, and color inequality defects are allowed. Both ends of the pipe shall be cut flat and perpendicular to the pipe axis.

|

||||

|

Table 1 Mechanical properties of the pipe |

|||||

|

NO |

Item |

Requirements |

Test parameters |

Test method

|

|

|

1 |

Hydrostatic strength (20℃,100h) |

No damage, no leakage |

Ring stress: PE80 PE100 Test time Test temperature |

9.0 Mpa 12.0MPa >100h 20℃ |

GB15558.1-20156.2.4 |

|

2 |

Hydrostatic strength (80℃,165h) |

No damage, no leakage |

Ring stress: PE80 PE100 Test time Test temperature |

4.5 Mpa 5.4MPa >165h 80℃ |

GB15558.1-20156.2.4 |

|

3 |

Hydrostatic strength (80C,1000h) |

No damage, no leakage |

Ring stress: PE80 PE100 Test time Test temperature |

4.0 Mpa 5.0MPa >1000h 80℃ |

GB15558.1-20156.2.4 |

|

4 |

Elongation at breake<5mm |

>350% |

Sample shape Test Speed |

Type2100mm/min |

GB15558.1-20156.2.5 |

|

Elongation at break5mm<e<12mm |

>350% |

Sample shape Test Speed |

Type150mm/min |

||

|

Elongation at breake>12mm |

>350% |

Sample shape Test Speed |

Type 125mm/min |

||

|

or |

|||||

|

Sample shape Test Speed |

Type310mm/min |

||||

|

5 |

Slow crack growth resistance e<5mm (cone test) |

<10mm/24h |

- |

GB155586.2 |

|

|

6 |

Slow crack growth resistance e>5mm (notch test) |

No damage, no leakage |

Test temperature Internal test pressure PE80,SDO11 PE100,SDR11 Test time |

80℃ 0.80 MPa 0.92 Mpa >500h

|

GB15558.1-20156.2.6 |

|

7 |

Resistance to rapid crack growth (RCP) |

Pc.S4≥MOP/2.4-0.072,Mpa |

Test temperature |

0℃ |

GB15558.1-20156.2.7 |

|

Table 2 Physical properties of pipes |

|||||

|

No |

Item |

Requirements |

Test parameters |

Test method |

|

|

1 |

Oxidation induction time (thermal stability) |

>20 min |

Test temperature |

200℃(15±2)mg |

GB15558.1-20156.2.8 |

|

2 |

Melt mass flow rate (MFR)(g/10min) |

Change of MFR before and after processing<20% |

Load mass test temperature |

5kg 190℃ |

GB15558.1-20156.2.9 |

|

3 |

Longitudinal retraction (wall thickness < 16mm) |

no surface damage<3%, |

Test temperature sample length placed in the oven time |

110℃200mm 1h |

GB15558.1-20156.2.10 |

|

Table 3 System suitability of butt welded joints |

|||||

|

No. |

Item |

Requirements |

Test method |

Test method |

|

|

1 |

Hydrostatic strength (80C,165h)b |

No damage, no leakage |

ring stress PE80PE100 |

4.5 MPa 5.4 MPa |

GB15558.1-20156.3.2 |

|

2 |

Tensile test |

test to failure Toughness failure through brittle failure did not pass |

Test temperature |

23℃ |

GB15558.1-20156.3.3 |

|

a.All components of the sample a joint shall have the same MRS And the same SDR, and the joint shall meet the minimum and maximum conditions. b.Only brittle failure is considered. If ductile failure occurs before 165h, the lower stress and corresponding minimum failure time should be selected for re-test according to Table 1. c. Suitable for pipes whose dn is not less than 90mm (en > 5mm).

|

|||||

CHUANGRONG has an excellent staff team with rich experience. Its principal is Integrity, Professional and Efficient. It has established business relationship with more than 80 countries and zones in relative industry. Such as United States, Chile, Guyana, The United Arab Emirates, Saudi Arabia, Indonesia, Malaysia,Bangladesh, Mongolia, Russia, Africa and so on.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

Polythylene PE80 /PE100/ MDPE Pipe For Natural Gas & Oil Pipe System

|

Nominal outside diameterDn(mm) |

Nominal wall thickness (en) |

|||

|

|

PE80 |

PE100 |

||

|

|

5Bar |

7Bar |

6Bar |

10 Bar |

|

|

SDR17.6 |

SDR11 |

SDR17.6 |

SDR11 |

|

20 |

2.3 |

3.0 |

2.3 |

3.0 |

|

25 |

2.3 |

3.0 |

2.3 |

3.0 |

|

32 |

2.3 |

3.0 |

2.3 |

3.0 |

|

40 |

2.3 |

3.7 |

2.3 |

3.7 |

|

50 |

2.9 |

4.6 |

2.9 |

4.6 |

|

63 |

3.6 |

5.8 |

3.6 |

5.8 |

|

75 |

4.3 |

6.8 |

4.3 |

6.8 |

|

90 |

5.2 |

8.2 |

5.2 |

8.2 |

|

110 |

6.3 |

10.0 |

6.3 |

10.0 |

|

125 |

7.1 |

11.4 |

7.1 |

11.4 |

|

140 |

8.0 |

12.7 |

8.0 |

12.7 |

|

160 |

9.1 |

14.6 |

9.1 |

14.6 |

|

180 |

10.3 |

16.4 |

10.3 |

16.4 |

|

200 |

11.4 |

18.2 |

11.4 |

18.2 |

|

225 |

12.8 |

20.5 |

12.8 |

20.5 |

|

250 |

14.2 |

22.7 |

14.2 |

22.7 |

|

280 |

15.9 |

25.4 |

15.9 |

25.4 |

|

315 |

17.9 |

28.6 |

17.9 |

28.6 |

|

355 |

20.2 |

32.3 |

20.2 |

32.3 |

|

400 |

22.8 |

36.4 |

22.8 |

36.4 |

|

450 |

25.6 |

40.9 |

25.6 |

40.9 |

|

500 |

28.4 |

45.5 |

28.4 |

45.5 |

|

560 |

31.9 |

50.9 |

31.9 |

50.9 |

|

630 |

35.8 |

57.3 |

35.8 |

57.3 |

CHUANGRONG and its affiliated companies specialize in the R&D, production, sale and installation of new-type plastic pipes and fittings. It owned five factories, one of the largest manufacturer and supplier of plastic pipes and fittings in China. Furthermore, the company owns more 100 sets pipe production lines that are advanced at domestic and abroad,200 sets of fitting production equipment. The production capacity reaches more than 100 thousand tons. Its main contain 6 systems of water, gas, dredging, mining, irrigation and electricity, more than 20 series and more than 7000 specifications

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

PE gas pipe is suitable for gas transportation on condition that working temperature is among -20°C~40°C , and long-term maximum working pressure is not more than 0.7MPa. CHUANGRONG Polyethylene Gas Pipe is suitable for Gas distribution network both for domestic & industrial consumption.

Low specific Weight

Excellent weldability

Smooth inside surface, no deposits and no overgrowth

Due to less frictional resistance, less pressure drop compared to metals

Suitable for food and potable water

Complies with the food stuff regulations

Approved and registered for potable water supply

Laying speed ease joining and reliability

We can supply ISO9001-2015,WRAS, BV ,SGS, CE etc certification. All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top