Welcome To CHUANGRONG

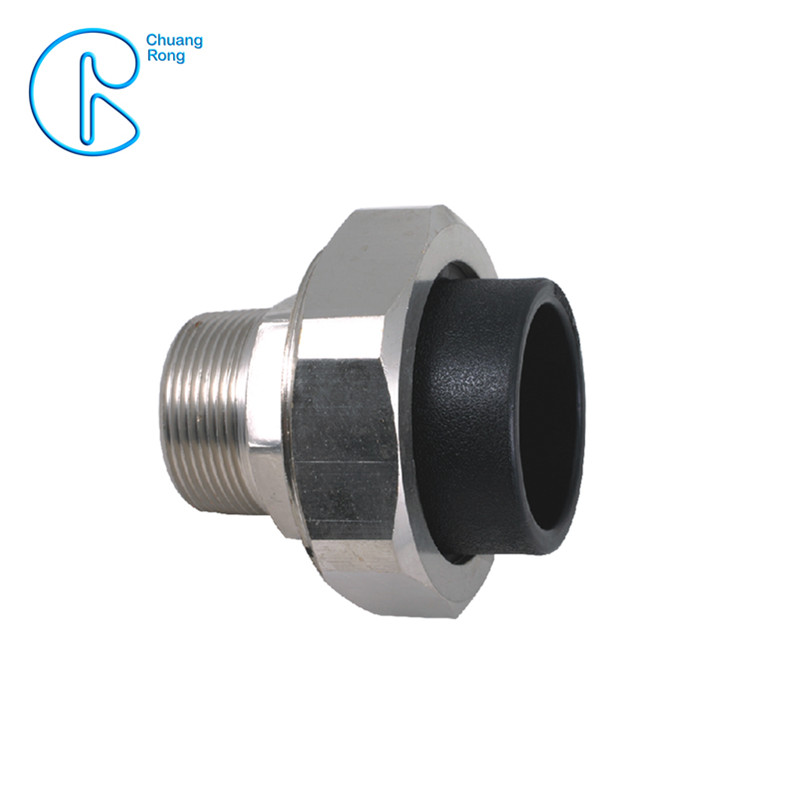

HDPE Socket Fusion Pipe Reducer Coupling PE100 PN16 SDR11 CE Approved

Detail Information

CHUANGRONG and its affiliated companies specialize in the R&D, production, sale and installation of new-type plastic pipes and fittings. It owned five factories, one of the largest manufacturer and supplier of plastic pipes and fittings in China. Furthermore, the company owns more 100 sets pipe production lines that are advanced at domestic and abroad,200 sets of fitting production equipment. The production capacity reaches more than 100 thousand tons. Its main contain 6 systems of water, gas, dredging, mining, irrigation and electricity, more than 20 series and more than 7000 specifications.

PE100 HDPE Socket Fusion Pipe Reducer Coupling

|

Type |

Specification |

Diameter(mm) |

Pressure |

|

Socket Fittings |

Coupler |

DN20-110mm |

PN16 |

|

|

Reducer |

DN25*20-DN110*90 |

PN16 |

|

|

90 Deg Elbow |

DN20-110mm |

PN16 |

|

|

45 Deg Ebow |

DN20-110mm |

PN16 |

|

|

Tee |

DN20-110mm |

PN16 |

|

|

Reducer Tee |

DN25*20 -DN110*90 |

PN16 |

|

|

Stub End |

DN20-110mm |

PN16 |

|

|

End Cap |

DN20-110mm |

PN16 |

|

|

Ball Valves |

DN20-63mm |

PN16 |

|

Threaded- Socket Fitting |

Female Adapter |

DN20X1/2'-110 X4' |

PN16 |

|

|

Male Adapter |

DN20X1/2'-110 X4' |

PN16 |

|

|

Female Elbow |

DN20X1/2'-63X2' |

PN16 |

|

|

Female Tee |

DN20X1/2'-63X2' |

PN16 |

|

|

Male Tee |

DN20X1/2'-63X2' |

PN16 |

|

|

Stop Valve |

DN20-110mm |

PN16 |

|

|

Female Union |

DN20X1/2'-63X2' |

PN16 |

|

|

Male Union |

DN20X1/2'-63X2' |

PN16 |

Welcome to visit our factory or conduct a third-party audit.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com

Product Description

CHUANGRONG HDPE socket fittings are mainly used to connect OD20-110mm pipelines, and are used for water supply, gas, irrigation, etc.

Socket welding principle: This method of connecting pipes and fittings involves a heating tool that can simultaneously heat plastic pipes and fittings to a melting point. In this case, the molten pipe can be melted by inserting it To connect the two in the socket of the accessory.

Once properly inserted and allowed to cool, these two parts become a continuous bond of HDPE plastic, unable to separate and form a stronger connection than its parts.

CHUANGRONG manufactures a full line of HDPE socket fusion fittings, in which the outer diameter of the pipe is controlled over the entire thickness of the side wall. We offer stocks of the following socket welding sizes: OD20-110mm, 1/2 “, 3/4″, 1 “, 1 1/4″, 1 1/2 “, 2″. And comprehensive types: casing, elbow, tee, flange head, inner and outer wire fittings.

| Products name | Socket Joint Fusion HDPE Reducing Coupling |

| Sizes | 20-110mm |

| Connection | Socket Joint Fusion |

| Executive Standard | EN 12201-3:2011 |

| Colors Available | Black color , blue color, Orange or as request. |

| Packing Method | Normal export packing. by carton |

| Production Lead Time | Depending on the order quantity.Normally about 15-20 days for 20ft container, 30-40 days for a 40ft container |

| Certificate | WRAS,CE,ISO,CE |

| Supply Ability | 100000 Ton/Year |

| Payment Method | T/T, L/C at sight |

| Trading Method | EXW, FOB, CFR, CIF, DDU |

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

|

specifications |

L mm |

L1 mm |

L2 mm |

|

S25×20 |

38 |

16 |

14.5 |

|

S32×20 |

41 |

18.1 |

14.5 |

|

S32×25 |

40 |

18.1 |

16 |

|

S40×20 |

47.5 |

20.5 |

14.5 |

|

S40×25 |

46.5 |

20.5 |

16 |

|

S40×32 |

46.5 |

20.5 |

18.1 |

|

S50×20 |

59 |

23.5 |

14.5 |

|

S50×25 |

53 |

23.5 |

16 |

|

S50×32 |

52 |

23.5 |

18.1 |

|

S50×40 |

52 |

23.5 |

20.5 |

|

S63×20 |

64 |

27.4 |

14.5 |

|

S63×25 |

63 |

27.4 |

16 |

|

S63×32 |

62 |

27.4 |

18.1 |

|

S63×40 |

60 |

27.4 |

20.5 |

|

S63×50 |

58.5 |

27.4 |

23.5 |

|

S75×32 |

78 |

31 |

18.1 |

|

S75×40 |

76.5 |

31 |

20.5 |

|

S75×50 |

75 |

31 |

23.5 |

|

S75×63 |

74 |

31 |

27.4 |

1.Municipal water supply, gas supply and agriculture etc.

2.Commercial & Residential water supply.

3.Industrial liquids transportation.

4.Sewage treatment.

5. Food and chemical industry.

6. Replacement of cement pipes and steel pipes.

7. Argillaceous silt, mud transportation.

8. Garden green pipe networks

We can supply ISO9001-2015, BV ,SGS, CE etc certification.All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top