Welcome To CHUANGRONG

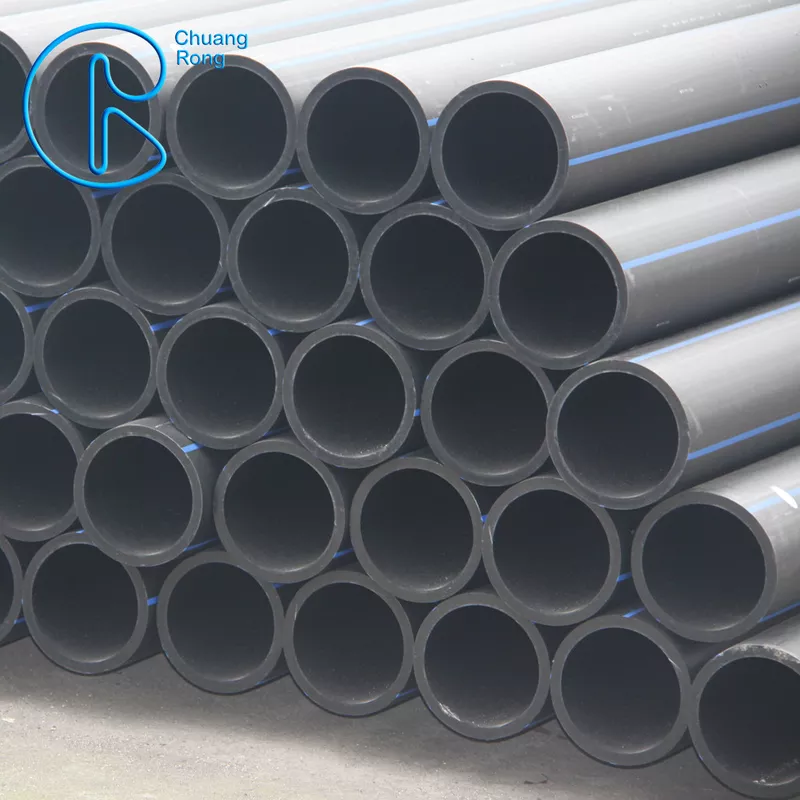

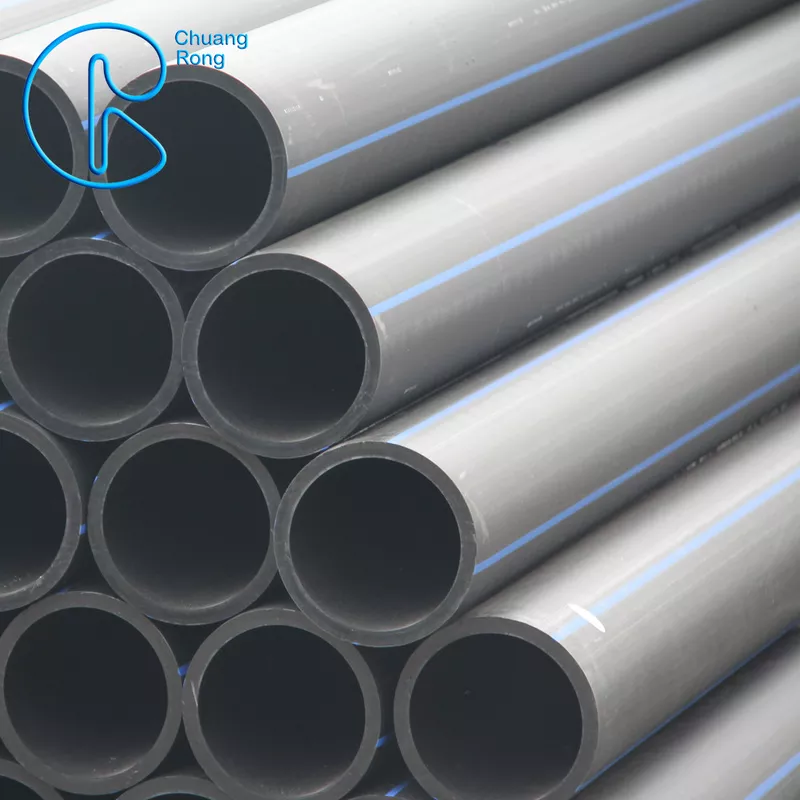

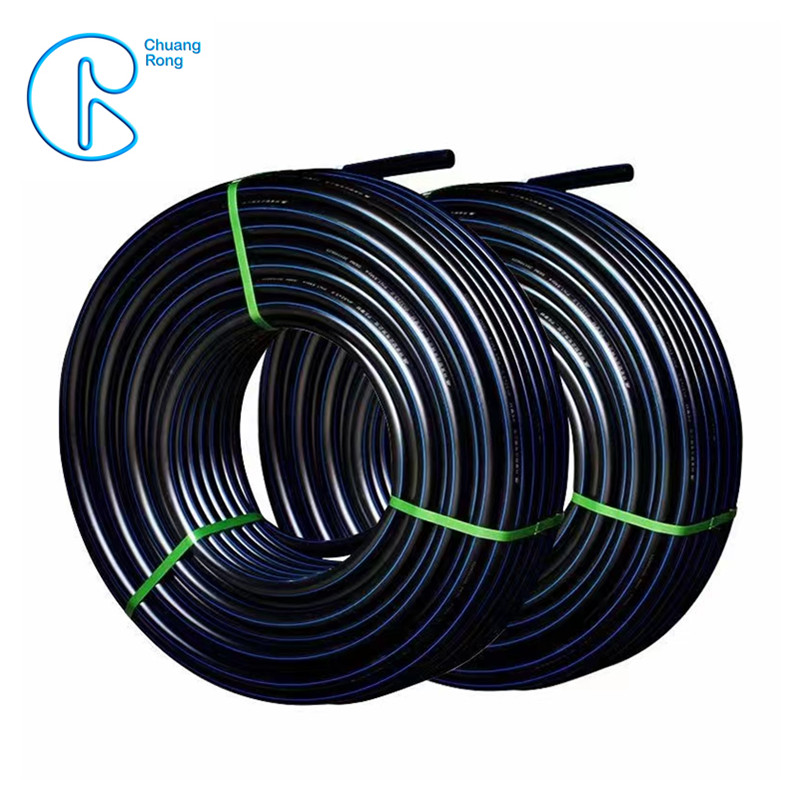

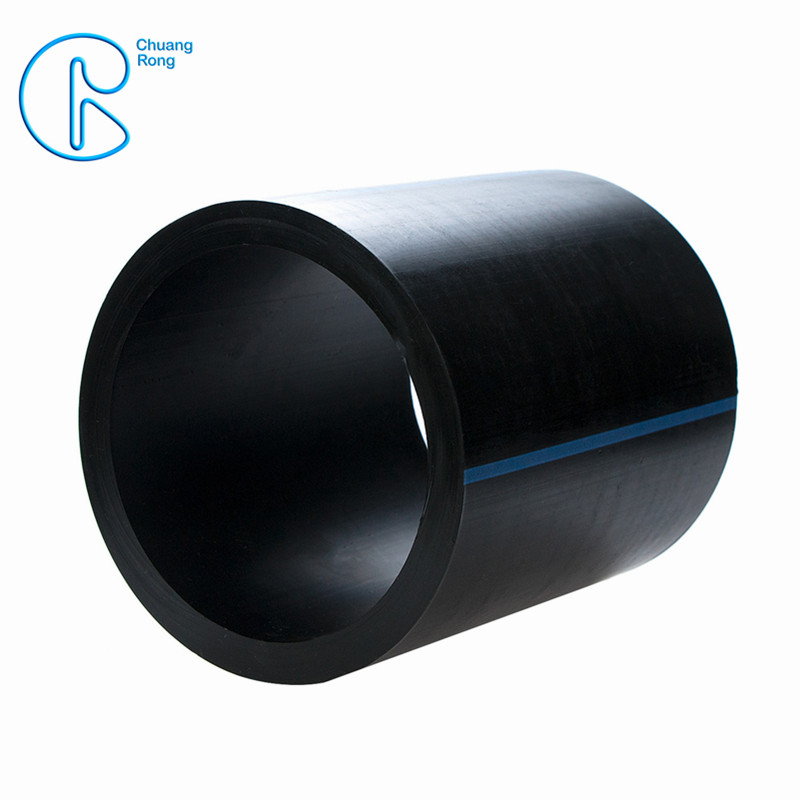

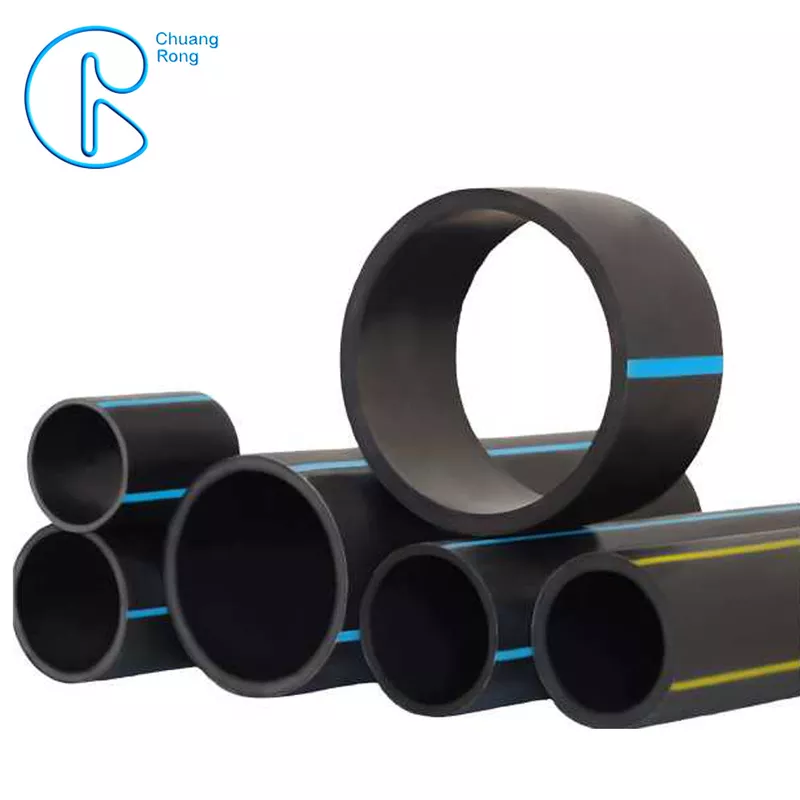

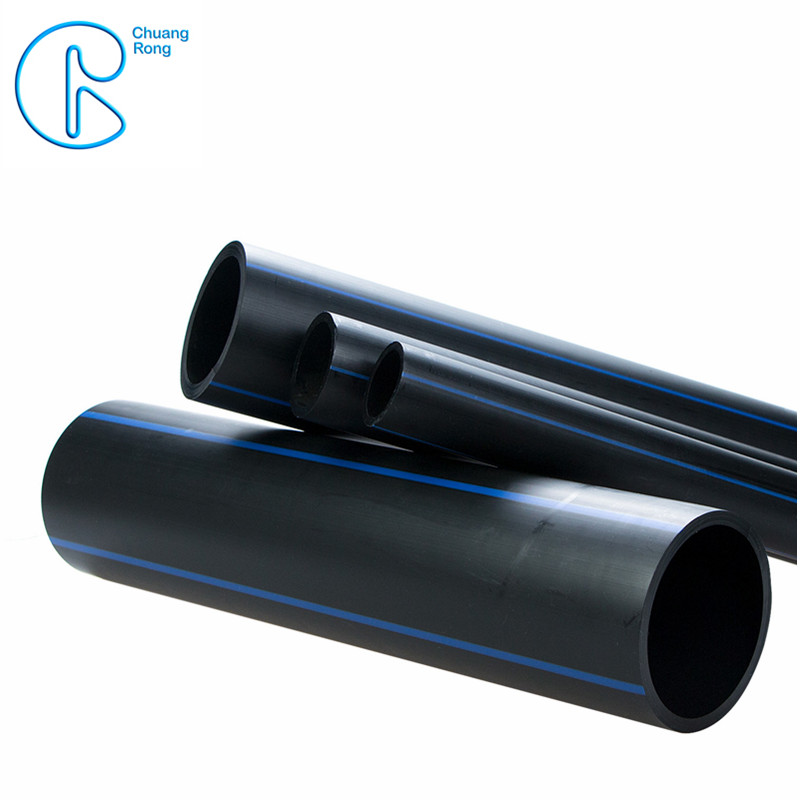

Black PE100-RC Resist Crack Corrosion Resistance HDPE Pipe For Water and Gas Supply

Basic Information

CHUANGRONG's mission is providing different customers with perfect one-stop solution for plastic pipe system. It can supply professionally designed, customized service for your project.

Black PE100-RC Resist Crack Corrosion Resistance HDPE Pipe For Water and Gas Supply

|

Products Details |

Company/Factory Strength |

||

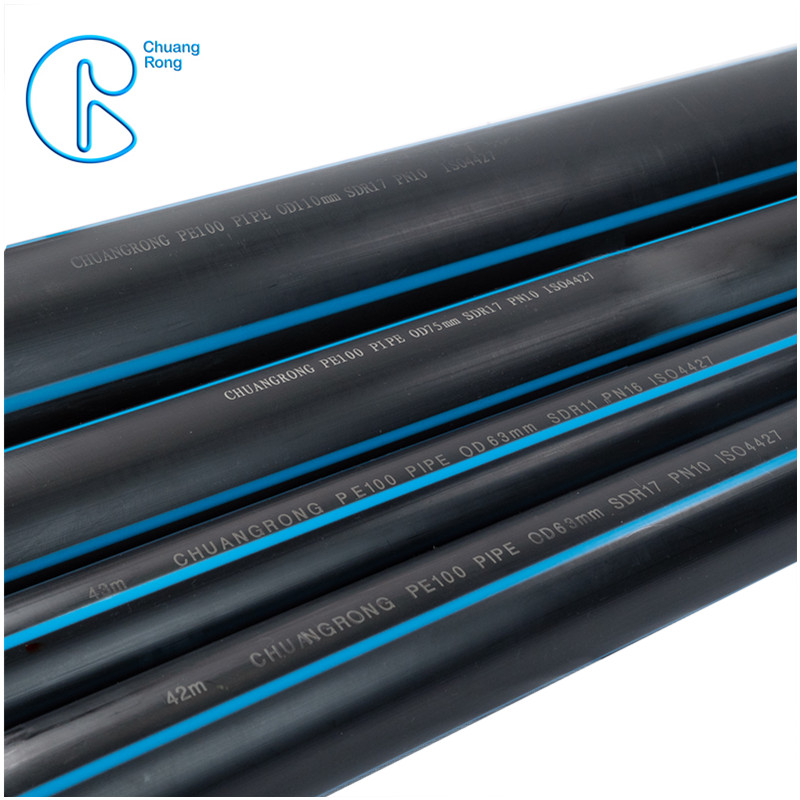

| Name | High Density Polyethylene (HDPE) Drinking Water Pipe | Production Capacity | 100,000 Ton/Year |

| size | DN20-1600mm | Sample | Free sample available |

| Pressure | PN4- PN25, SDR33-SDR7.4 | Delivery time | 3-15 days, depending on the quantity |

| Standards | ISO 4427, ASTM F714, EN 12201, AS/NZS 4130, DIN 8074, IPS | Test/inspection | National standard laboratory, Pre-delivery inspection |

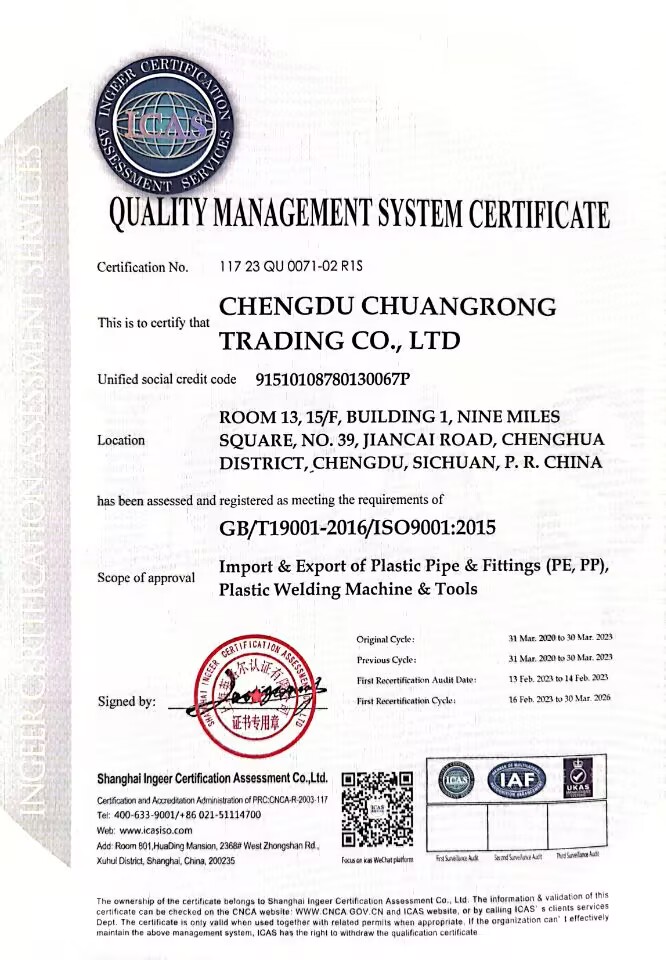

| Raw Material | 100% Virgin l PE80, PE100, PE100-RC | Certificates | ISO9001, CE, WRAS, BV, SGS |

| Color | Black with blue stripes, Blue or others colors | Warranty | 50 years with normal use |

| Packing | 5.8m or 11.8m/length, 50-200m/roll, for DN20-110mm. | Quality | QA & QC system, Ensure traceability of each process |

| Application |

Drinking water, Fresh water, Drainage, Oil and Gas, Mining, Dredging, Marine, Irrigation, Industry, Chemical, Fire fighting... |

Service | R&D, production, sale and installation, after-sales service |

|

Matching products: Butt fusion, Socket fusion, Electrofusion, Drainage, Fabricated, Machined fitting, Compression fittings, Plastic Welding machines and tools, etc. |

|||

Welcome to visit our factory or conduct a third-party audit.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com

Product Description

CHUANGRONG PE100-RC DN20-DN1600 HDPE PIPE

Polyethylene pipe materials have gone through 4 stages.

The first stage started in the 1950s, and mainly consisted of polyethylene macromolecules without branching; the second was PE80 material; the third was PE100 material; the fourth passed the Molecular structure design.

High toughness polyethylene PE100-RC pipe not only maintains the excellent toughness, good wear resistance and corrosion resistance of PE100 pipe, but also has the following characteristics:

1, With high toughness: high toughness polyethylene PE100-RC pipe elongation at break of more than 500%, high impact strength, resistance to strong shock and distortion. Under different crustal changes such as ground subsidence and earthquake, the pipeline will not break and has high safety.

2, High resistance to stress cracking: high toughness polyethylene PE100-RC pipe has super toughness, normal service life of more than 100 years. If the outer wall of the pipeline is scratched during transportation or construction, the scratch depth is less than 20% of the wall thickness, because its crack resistance growth rate is only one tenth of the high-density PE100 grade material, it can effectively ensure the normal operation of the pipe and extend the service life. Correspondingly, when the scratch depth of high-density PE100 pipe is greater than 10% wall thickness, it can not meet the standard requirements.

3, Scratch resistance: Because the surface hardness of PE100 -RChigh toughness polyethylene s pipe is higher than that of high-density PE100, under the same scratching action, the depth of scratch is reduced by 1/3 ~ 1/2 than that of high-density PE100 pipe.

4, High resistance to point load: During the operation of the pipeline, the outer wall is squeezed by hard things such as stones in the soil for a long time, forming an inward depression, which is called point load. PE100-RC high-toughness polyethylene pipe can effectively prevent the damage of point load, make the pipeline operation safer and more reliable, and truly meet the use of the pipeline for 50 years. During the operation of the high-density PE100 pipe, the outer wall is squeezed by hard materials such as stones for a long time, which will cause the inner wall of the pipe to bulge and local brittle cracking.

CHUANGRONG has an excellent staff team with rich experience. Its principal is Integrity, Professional and Efficient. It has established business relationship with more than 80 countries and zones in relative industry. Such as United States, Chile, Guyana, The United Arab Emirates, Saudi Arabia, Indonesia, Malaysia,Bangladesh, Mongolia, Russia, Africa and so on.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

PE100-RC Resist Crack Corrosion Resistance HDPE Pipe For Water and Gas Supply

|

PE100 |

0.4MPa |

0.5MPa |

0.6MPa |

0.8MPa |

1.0MPa |

1.25MPa |

1.6MPa |

2.0MPa |

2.5MPa |

|

Outside Diameter (mm) |

PN4 |

PN5 |

PN6 |

PN8 |

PN10 |

PN12.5 |

PN16 |

PN20 |

PN25 |

|

SDR41 |

SDR33 |

SDR26 |

SDR21 |

SDR17 |

SDR13.6 |

SDR11 |

SDR9 |

SDR7.4 |

|

|

Wall Thickness (en) |

|||||||||

|

20 |

- |

- |

- |

- |

- |

- |

2.0 |

2.3 |

3.0 |

|

25 |

- |

- |

- |

- |

- |

2.0 |

2.3 |

3 |

3.5 |

|

32 |

- |

- |

- |

- |

2.0 |

2.4 |

3.0 |

3.6 |

4.4 |

|

40 |

- |

- |

- |

2.0 |

2.4 |

3.0 |

3.7 |

4.5 |

5.5 |

|

50 |

- |

- |

2.0 |

2.4 |

3.0 |

3.7 |

4.6 |

5.6 |

6.9 |

|

63 |

- |

- |

2.5 |

3.0 |

3.8 |

4.7 |

5.8 |

7.1 |

8.6 |

|

75 |

- |

- |

2.9 |

3.6 |

4.5 |

5.6 |

6.8 |

8.4 |

10.3 |

|

90 |

- |

- |

3.5 |

4.3 |

5.4 |

6.7 |

8.2 |

10.1 |

12.3 |

|

110 |

- |

- |

4.2 |

5.3 |

6.6 |

8.1 |

10.0 |

12.3 |

15.1 |

|

125 |

- |

- |

4.8 |

6.0 |

7.4 |

9.2 |

11.4 |

14 |

17.1 |

|

140 |

- |

- |

5.4 |

6.7 |

8.3 |

10.3 |

12.7 |

15.7 |

19.2 |

|

160 |

- |

- |

6.2 |

7.7 |

9.5 |

11.8 |

14.6 |

17.9 |

21.9 |

|

180 |

- |

- |

6.9 |

8.6 |

10.7 |

13.3 |

16.4 |

20.1 |

24.6 |

|

200 |

- |

- |

7.7 |

9.6 |

11.9 |

14.7 |

18.2 |

22.4 |

27.4 |

|

225 |

- |

- |

8.6 |

10.8 |

13.4 |

16.6 |

20.5 |

25.2 |

30.8 |

|

250 |

- |

- |

9.6 |

11.9 |

14.8 |

18.4 |

22.7 |

27.9 |

34.2 |

|

280 |

- |

- |

10.7 |

13.4 |

16.6 |

20.6 |

25.4 |

31.3 |

38.3 |

|

315 |

7.7 |

9.7 |

12.1 |

15 |

18.7 |

23.2 |

28.6 |

35.2 |

43.1 |

|

355 |

8.7 |

10.9 |

13.6 |

16.9 |

21.1 |

26.1 |

32.2 |

39.7 |

48.5 |

|

400 |

9.8 |

12.3 |

15.3 |

19.1 |

23.7 |

29.4 |

36.3 |

44.7 |

54.7 |

|

450 |

11 |

13.8 |

17.2 |

21.5 |

26.7 |

33.1 |

40.9 |

50.3 |

61.5 |

|

500 |

12.3 |

15.3 |

19.1 |

23.9 |

29.7 |

36.8 |

45.4 |

55.8 |

- |

|

560 |

13.7 |

17.2 |

21.4 |

26.7 |

33.2 |

41.2 |

50.8 |

62.5 |

- |

|

630 |

15.4 |

19.3 |

24.1 |

30 |

37.4 |

46.3 |

57.2 |

70.3 |

- |

|

710 |

17.4 |

21.8 |

27.2 |

33.9 |

42.1 |

52.2 |

64.5 |

79.3 |

- |

|

800 |

19.6 |

24.5 |

30.6 |

38.1 |

47.4 |

58.8 |

72.6 |

89.3 |

- |

|

900 |

22 |

27.6 |

34.4 |

42.9 |

53.3 |

66.2 |

81.7 |

- |

- |

|

1000 |

24.5 |

30.6 |

38.2 |

47.7 |

59.3 |

72.5 |

90.2 |

- |

- |

|

1200 |

29.4 |

36.7 |

45.9 |

57.2 |

67.9 |

88.2 |

- |

- |

- |

|

1400 |

34.3 |

42.9 |

53.5 |

66.7 |

82.4 |

102.9 |

- |

- |

- |

|

1600 |

39.2 |

49 |

61.2 |

76.2 |

94.1 |

117.6 |

- |

- |

- |

PE100-RC Super Tough Polythylene Pipe Physical and Mechanical Properties

|

No. |

Performance |

Unit |

Requirement |

Requirement |

Requirement |

|

1 |

Hydrostatic strength |

h |

No damage, no leakage |

20℃, 12.0MPa , ≥100h |

GB/T 6111 |

|

80℃,5.4MPa,≥165h |

|||||

|

80℃, 5.0MPa,≥1000h |

|||||

|

2 |

Elongation at break e≤5mm |

% |

≥350b,c |

type 2d 100mm/min |

GB/T 8804.3 |

|

Elongation at break 5mm<e≤12mm |

type 1d 50mm/min | ||||

|

Elongation at break e>12mm |

type 1d 25mm/mintype 3d 10mm/min | ||||

|

3 |

Slow crack growth resistance (pipe cone test)) en≤5mm |

mm/48h |

<1 |

80℃ |

GB/T 19279 |

|

4 |

Slow crack growth resistance (pipe notch test) en>5mm |

h |

failure time ≥8760 |

80℃,0.92MPa (test pressure) |

GB/T 18476 |

|

5 |

Full incision creep test(FNCT) |

h |

failure time ≥8760 |

80℃,4.0MPa,2% nonylphenol polyoxyethylene ether solution |

DIN/PAS 1075 |

|

6 |

Point load test |

h |

failure time ≥8760 |

0℃,4MPa,2% nonylphenol polyoxyethylene ether solution |

DIN/PAS 1075 |

|

7 |

Fast Crack growth resistance(RCP) |

Mpa |

Pcs≥MOP/2.4-0.072 |

- |

GB/T 19280 |

|

8 |

Compression Recovery |

- |

Pcs≥MOP/2.4-0.072 |

0℃ |

GB/T 15558.1-2015 |

|

9 |

Thermal stability |

min |

>20 |

200℃ |

GB/T 19466.6 |

|

10 |

Thermal stability(MFR) |

g/10min |

change before and after processing <20% |

5kg,190℃ |

GB/T 3682 |

|

11 |

Longitudinal retraction (wall thickness ≤16mm) |

% |

≤3,no surface damage |

110℃,200mm,1h |

GB/T 6671 |

a. Only brittle failure is considered. If ductile failure occurs before 165h, the lower stress and corresponding minimum failure time are selected according to the standard to re-test.

b. If the damage occurs outside the standard distance, the test is considered to be passed if the test value meets the requirements.

c. When the required test value is reached, the test can be stopped without the need to test until the sample is damaged.

d. If feasible, pipe with wall thickness not greater than 25mm can also be used type 2 sample, type 2 sample by machining or molding method.

e. For pressure values corresponding to other SDR series, see GB/T 18476.

f. The RCP test shall be performed only when the pipe produced by the pipe manufacturer is greater than the wall thickness of the pipe used in the RCP test provided by the mixed ingredients manufacturer. When applied below 0 ° C, RCP tests are required at this temperature to determine the critical pressure at the minimum operating temperature. When testing according to GB/T 19280, if the S4 test fails to meet the requirements, the test should be re-tested according to the full-size test, and the results of the full-size test should be used as the final judgment basis.

Welcome to contact us for products details and professional service.

Please send email to: chuangrong@cdchuangrong.com or Tel: + 86-28-84319855

HDPE pipes have been in existence since the mid 50′s. The experience shows that HDPE pipes is the solution to most pipe problems being recognized by clients and engineering consultants as the ideal pipe material for many pressure and non pres-sure applications from water and gas distribution to gravity, Sewers and surface water drainage for both new & Rehabilitation Projects. Chuangrong polyethylene pipes is based on a polytholefin thermoplastic resin which is also a physiologically non-toxic material, therefore, it is suitable for a wide range of applications.

Suitable for:

Water Supply. Chuangrong PE pipes are made from material meeting the toxicity requirement of the WHO and this can be used for transportation of drinking water.

-Pipes and fittings with pressure ratings of SDR 7.4 up to SDR 41 for water mains as well as distribution piping systems and service lines.

-Drain pipes and fittings for spring water chamber pipes.

-Ascending pipes for wells.

In contrast for pipes mad of steel or ductile iron, HDPE piping systems are light weight and corrosion resistant. Neither sour soils nor “aggressive” water will have no effect to the material. Additionally,corrosion products,which often impair the operability of the piping system, are avoided. In comparison to PVC pipes, HDPE pipes are more flexible and offer high impact resistance even in zero temperatures. The pipes may be adapted easily to the trench layout without employing additional fittings.On the other hand, fracture risks due to extreme handling conditions on the construction site are minimized. HDPE piping systems (spigot and socket joints) offer a range of longitudinal frictional connection methods. Thus, the installation of anchors or thrust blocks is not necessary and a leak proof piping system with a long life is guaranteed.

Highest drinking water quality. The suitability of the material for drinking water is ensured through independent tests.Neither the taste nor the smell of the drinking water is affected due to the contact with HDPE pipes. The smooth surface and the high abrasion resistance guarantee minimum deposits. Polyethylene is corrosion resistant, therefore, the drinking water cann ot be contaminated with corrosion by-products like copper or heavy metals such as cadmium or lead, which happens frequently with older metal piping systems.

Environmental Friendly material for a clean environment. The HDPE pipes and fitting are exclusively made from the environmentally friendly materials. For instance, the energy requirements for the production of HDPE pipes is lower n result from the production of the pipes is made of polyethylene. The application of HDPE piping systems provides the best solution for the environment. A 100% leak proof supply system may be installed with simple welding methods. Thus, endangering the drinking water with toxic substances is reduced. Additionally, water loss due to leaking piping systems are avoided. No other supply system offers these advantages.

For extreme conditions. HDPE piping systems are approved for installation in all types of soil. Polyethylene is a flexible application of various jointing methods encases a leak proof supply system. Due to the light weight and the simple jointing methods, HOPE pipes are very well suitable for unfavourable conditions- for the installation in difficult terrain.

Drainage.Chuangrong pipes are being used for underground drainage for buildings, waste lines for corrosive fluids and also as as a perfect material for the manufacturer of large bore pipes for sewage systems.They are ideally suited for industrial waste disposal and are being used to an increasing extent as underground sewer and waste pipes.

Industry.Features like corrosion-resistance, easy installation, light weight, and flexibility make chuangrong pipes ideal for complicated plumbing in factories. They are ideal for corrosive chemicals.

Gas and Oil Pipeline Systems. PE pipes to line carbon steel pipes to transport oil & gases at higher pressure are avail-able. The pipes are specially designed with a smooth surface and made easy to install. Thus gas lines can be installed at low costs. In drilling they are used as shot-hole casings as they are cheaper.Due to the excellent properties of HDPE,which exhibit a high impact strength and very good resistance aggressive soils.Combined with ease of handling and installation, the HDPE pipes are excellent for transporting material and other gas types including bio-gas.

CHUANGRONG possesses complete detection methods with all kinds of advanced detection equipment to ensure the quality control in all processes from raw material to finished product. The products are in line with ISO4427/4437, ASTMD3035, EN12201/1555, DIN8074, AS/NIS4130 standard, and approved by ISO9001-2015, CE, BV, SGS, WRAS.

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top