Welcome To CHUANGRONG

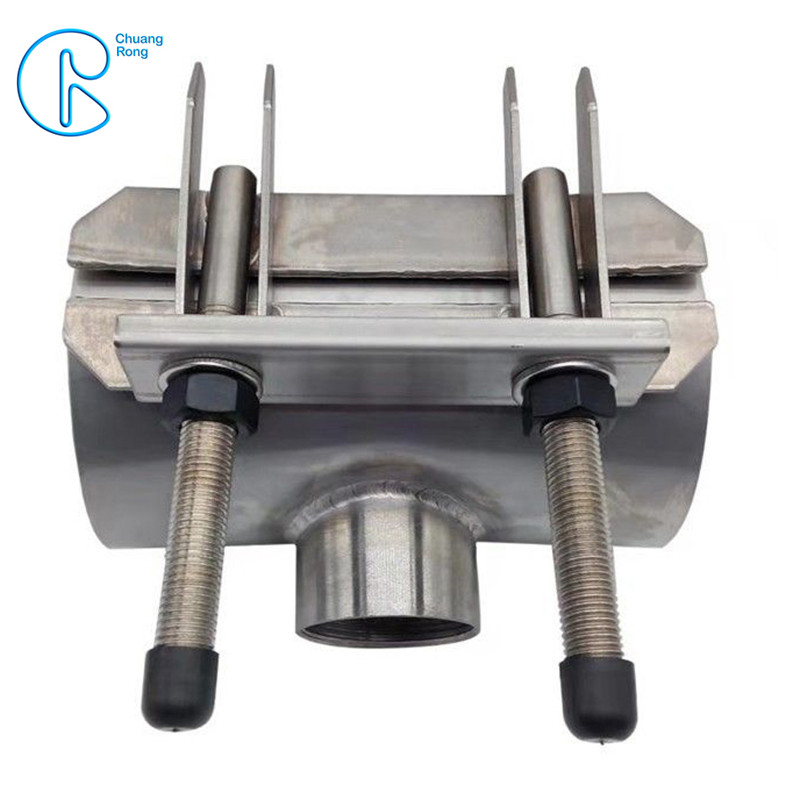

Socket Fusion Machine CRJQ-63mm Manual PPR Fitting Connection Equipment

Basic Information

| Model: | CRJQ-63 | Working Range: | 20-63mm |

|---|---|---|---|

| Max Working Range: | 63mm | Material: | PPR -PVDF |

| Working Environment: | -20℃~50℃ | Relative Humidity: | 45%~95% |

Product Description

Specification

| ternal diameter(mm) | Melting depth(mm) | Heating time(s) | Processing time(s) | Cooling time(min) | |

| A | B | ||||

| 20 | 14.0 | 14.0 | 5 | 4 | 3 |

| 25 | 15.0 | 16.0 | 7 | 4 | 3 |

| 32 | 16.5 | 18.0 | 8 | 4 | 4 |

| 40 | 18.0 | 20.0 | 12 | 6 | 4 |

| 50 | 20.0 | 23.0 | 18 | 6 | 5 |

| 63 | 24.0 | 27.0 | 24 | 6 | 6 |

Instruction for use

1.Coating diePlace the welding machine on the support, select the die according to the diameter of the pipe, and then fix it on the machine. Usually, the little endian is at the front and the big endian is at the back.

2. Power onTurn on the power (make sure the power supply has a leakage protector), the green and red lights are on, wait until the red light goes out and keep the green light on, indicating that the machine has entered the automatic temperature control mode and the machine can be used.Note: In the automatic temperature control mode, the red and green lights will alternate on and off, which indicates that the machine is in a controlled state and will not affect operation.

3.Fusion tubeCut the tube vertically with a cutter, push the tube and fittings into the die, do not rotate. Remove them as soon as the heating time is reached (see table Above) and insert

Packing

Send your message to us:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top